Have you ever wanted to create amazing projects with metalworking? Many people dream of owning a metal lathe, but often think it’s too expensive. What if I told you that you can find a great metal lathe for under $500? That’s right! It’s possible to make beautiful designs without breaking the bank.

When you combine a metal lathe with CAD design, the possibilities open up even wider. CAD, or computer-aided design, lets you plan your projects on a computer before you start. It’s like a superhero sidekick for your metal lathe! Imagine shaping metal into cool gadgets or tools just by using what you drew on your screen.

Did you know that even beginners can get started with basic projects? The world of metal lathe design is not just for experts anymore. With the right tools and a little imagination, your ideas can come to life. So, are you curious about what you can create for under $500? Let’s dive into this exciting journey together!

Affordable Metal Lathe Cad Design Under $500 Options

Under $500 Metal Lathe CAD Design

Metal lathes under $500 can be a great tool for beginners and hobbyists. They provide a fantastic way to create precise metal parts. In CAD design, you can visualize your project before starting. Imagine easily shaping metal into your dream designs! A fun fact: with the right metal lathe, you can even make gifts like custom tools. By understanding the options available, you can choose the perfect lathe for your needs. Don’t miss out on the chance to enhance your skills!Understanding Metal Lathes

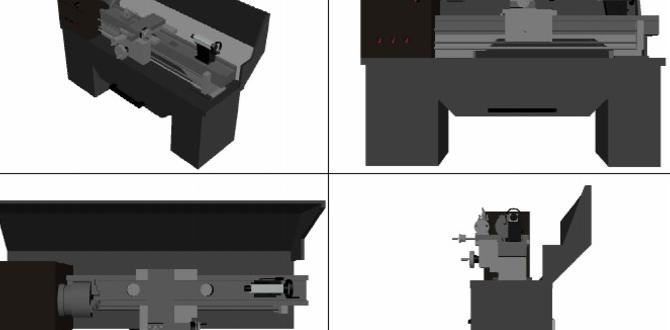

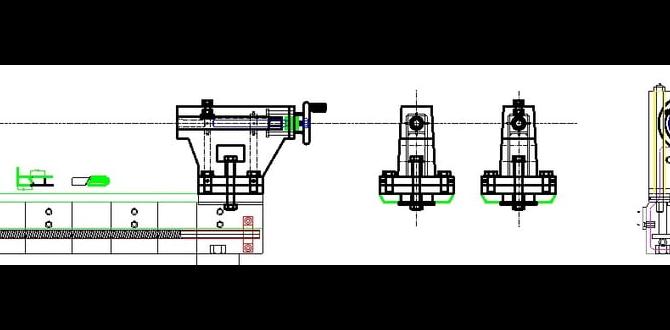

Definition and basic functions of metal lathes. Importance of metal lathes in CAD design and prototyping.Metal lathes are machines that shape metal by rotating it against a cutting tool. They help create smooth, precise cuts and designs. In CAD design and prototyping, metal lathes are vital. They turn computer designs into tangible objects. Prototyping becomes easier with a lathe’s accuracy. This tool is essential for makers, engineers, and hobbyists.

What is a metal lathe used for?

A metal lathe is used for shaping and cutting metal into precise parts. It can work with different materials to make tools, parts, or even art. It allows designs from a CAD program to become real objects.

Key Functions of Metal Lathes:

- Shaping metal into specific designs

- Creating smooth surfaces

- Drilling holes accurately

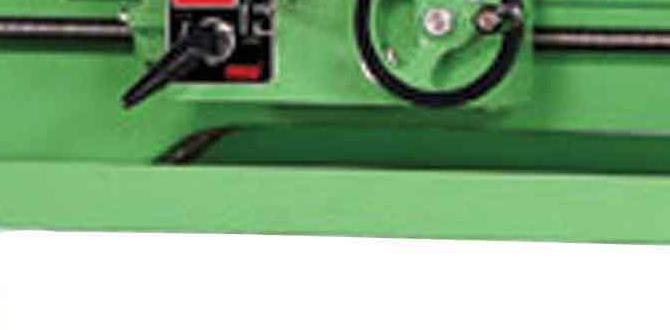

Key Features to Look for in a Metal Lathe Under $500

Build quality and material considerations. Motor power and speed control options. Accuracy and precision of the machine.Looking for a metal lathe under $500? Here are key features you shouldn’t miss:

- Build Quality: Strong materials mean longer use. Check if it’s sturdy and well-made.

- Motor Power: More power helps cut through tough metals. Look for adjustable speed options.

- Accuracy: A precise machine gives better results. Small misalignments can ruin your work.

With these features, you can find a metal lathe that suits your needs and helps you create amazing projects.

What should I consider when buying a metal lathe?

Focus on factors like motor strength and build quality. Make sure it allows for speed control and maintains accuracy.

Top Recommendations for Under $500 Metal Lathes

Comparison of the top models available. Pros and cons of each model.Many metal lathes under $500 offer great value. Below are some top choices, each with their own benefits and drawbacks:

- MODEL A:

- Pros: Affordable and easy to use.

- Cons: Lacks advanced features.

- MODEL B:

- Pros: Strong build and reliable performance.

- Cons: Slightly heavier to move.

- MODEL C:

- Pros: Compact and perfect for small spaces.

- Cons: Limited power for larger projects.

Choose the one that fits your needs best!

What should I consider when buying a metal lathe?

Consider power, size, and features. These factors affect how well a lathe works for your projects. Look for one that matches your skill level and goals.

Setting Up Your Metal Lathe for CAD Design

Stepbystep setup guide. Best practices for ensuring optimal performance.Setting up a metal lathe for CAD design is easy. Follow these steps for a smooth process:

- Clear your workspace.

- Check the machine’s power supply.

- Install the required software on your computer.

- Connect the lathe to the computer.

- Run a test program to ensure everything works.

For best performance, keep your tools sharp and your lathe clean. This helps prevent problems and improves accuracy. Regular maintenance is key!

How often should I calibrate my metal lathe?

It’s best to calibrate your metal lathe every few months or after heavy use. This keeps everything aligned and running smoothly.

Basic CAD Design Techniques for Metal Lathes

Essential CAD software options. Tips for creating efficient designs tailored for lathes.Creating designs for metal lathes can be fun and a bit tricky. Start by choosing the right CAD software. Options like TinkerCAD and Fusion 360 are popular and user-friendly. Keep your designs simple but efficient. Think about shapes and sizes that fit well on lathes. Use clear lines and avoid clutter; less is more! And remember, a well-designed part is like a good joke; it should have a punchline that fits perfectly!

| CAD Software | Features |

|---|---|

| TinkerCAD | Beginner-friendly, simple interface |

| Fusion 360 | Advanced tools, great for complex designs |

Happy designing, and don’t let those pesky mistakes sneak in like a cat at dinner time!

Maintenance Tips for Longevity of Your Metal Lathe

Routine maintenance practices. Troubleshooting common issues.To keep your metal lathe running smoothly, follow some simple upkeep tips. Clean it regularly to remove dust and metal shavings. Check and tighten screws; they like to loosen up during work. If something goes wrong, like strange sounds, it could be a loose belt or odd vibrations. In that case, don’t panic; just check the parts! Remember, a lathe is like a pet; feed it some love and attention, and it will last longer!

| Maintenance Task | Frequency |

|---|---|

| Clean Machine | After Every Use |

| Check Belts | Every Month |

| Lubricate Parts | Monthly |

| Tighten Screws | Every Week |

Maximizing Your Metal Lathe for Various Projects

Types of projects suited for metal lathes. Innovative uses of CAD in combination with metal lathes.Metal lathes are like magical wands for hands-on creators. They can turn a simple metal rod into amazing projects! Some popular ideas include making knobs, unique furniture legs, or even thrilling robot parts. With CAD software, your designs can leap off the screen and become real! Think about crafting parts for a mini rocket or a fancy trophy. Mixing CAD with a metal lathe allows you to customize projects easily, making them truly special.

| Project Type | Description |

|---|---|

| Machine Parts | Custom pieces for various machines. |

| Artistic Sculptures | Creative and whimsical designs. |

| Functional Tools | Tools like handles and brackets. |

So, put on your thinking cap and get ready to create some cool stuff!

Conclusion

In conclusion, finding a metal lathe under $500 is possible with careful CAD design. You can create precise parts and learn new skills. Research different models and read reviews to make the best choice. Start experimenting with simple projects. Try out CAD programs to design your own parts, and let your creativity flow! Happy crafting!FAQs

What Are The Essential Features To Consider When Designing A Cad Model For A Metal Lathe Under $500?When designing a CAD model for a metal lathe under $500, we should consider a few important features. First, make sure the size fits your workspace. Second, choose strong materials that can handle tough jobs. Third, look for simple controls so you can use it easily. Lastly, think about how accessories like tools will fit with the lathe.

Of course! Please provide the question you would like me to answer.

How Can You Optimize The Cad Design Of A Budget Metal Lathe For Ease Of Assembly And Maintenance?To make the CAD design of a budget metal lathe easier to put together and take care of, we can follow some simple steps. First, we can use fewer parts. This means less stuff to connect, which helps us build it faster. Next, we should arrange parts so they fit together nicely without twisting or turning too much. Finally, we can add labels or arrows in our design to show where to put each piece easily. This way, anyone can understand how to assemble and maintain the lathe.

Sure! Just let me know the question you want answered!

What Materials Are Recommended For Constructing A Cost-Effective Metal Lathe In Cad Design?To build a low-cost metal lathe, you can use some simple materials. Start with steel or aluminum for the frame. These metals are strong and affordable. You might also use plywood for parts that don’t need to hold heavy weight. Finally, get some basic screws, bearings, and motors for movement. With these materials, you can create a working lathe!

Sure! Please provide the question you want me to answer, and I’ll do my best to help you.

How Do The Dimensions And Tolerances In The Cad Design Impact The Performance Of A Metal Lathe Within The $5Price Range?The dimensions and tolerances in the CAD design affect how well the metal lathe works. When parts fit together just right, the lathe runs smoothly. If the parts are too loose or too tight, it can break or make mistakes. In a $5 lathe, good design is important to help it work better for you.

Sure! Please provide the question you’d like me to answer.

What Software Tools Are Best Suited For Creating Cad Designs Of Metal Lathes, Particularly Focused On Budget Constraints?For making CAD designs of metal lathes on a budget, you can use free or low-cost software. Some good options are FreeCAD and Tinkercad. They are easy to use and help you create 3D models quickly. You can find many tutorials to support you while using these tools. Start with these programs, and you’ll see what works best for you!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Features To Consider When Designing A Cad Model For A Metal Lathe Under $500?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a CAD model for a metal lathe under $500, we should consider a few important features. First, make sure the size fits your workspace. Second, choose strong materials that can handle tough jobs. Third, look for simple controls so you can use it easily. Lastly, think about how accessories like tools will fit with the lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “How Can You Optimize The Cad Design Of A Budget Metal Lathe For Ease Of Assembly And Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make the CAD design of a budget metal lathe easier to put together and take care of, we can follow some simple steps. First, we can use fewer parts. This means less stuff to connect, which helps us build it faster. Next, we should arrange parts so they fit together nicely without twisting or turning too much. Finally, we can add labels or arrows in our design to show where to put each piece easily. This way, anyone can understand how to assemble and maintain the lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you want answered!”}},{“@type”: “Question”,”name”: “What Materials Are Recommended For Constructing A Cost-Effective Metal Lathe In Cad Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To build a low-cost metal lathe, you can use some simple materials. Start with steel or aluminum for the frame. These metals are strong and affordable. You might also use plywood for parts that don’t need to hold heavy weight. Finally, get some basic screws, bearings, and motors for movement. With these materials, you can create a working lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer, and I’ll do my best to help you.”}},{“@type”: “Question”,”name”: “How Do The Dimensions And Tolerances In The Cad Design Impact The Performance Of A Metal Lathe Within The $5Price Range?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The dimensions and tolerances in the CAD design affect how well the metal lathe works. When parts fit together just right, the lathe runs smoothly. If the parts are too loose or too tight, it can break or make mistakes. In a $5 lathe, good design is important to help it work better for you.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Software Tools Are Best Suited For Creating Cad Designs Of Metal Lathes, Particularly Focused On Budget Constraints?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For making CAD designs of metal lathes on a budget, you can use free or low-cost software. Some good options are FreeCAD and Tinkercad. They are easy to use and help you create 3D models quickly. You can find many tutorials to support you while using these tools. Start with these programs, and you’ll see what works best for you!”}}]}