Have you ever thought about making your own parts with a metal lathe? It’s easier than you might think. For those looking to dive into the world of machining, finding a good metal lathe under $500 is a great start.

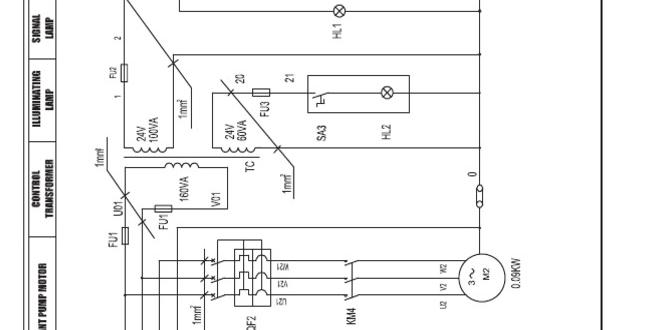

But wait—do you know how to wire it properly? A clear wiring diagram can save you time and confusion. Imagine spinning metal and creating cool projects in your garage.

In this article, you will discover the **under $500 metal lathe wiring diagram**. You’ll learn the key steps to set up your machine safely and easily. Plus, we’ll share tips to make your first project a success.

So, are you ready to unleash your creativity? Let’s get started on this exciting journey!

Under $500 Metal Lathe Wiring Diagram Guide For Beginners

Understanding the Under $500 Metal Lathe Wiring Diagram

A metal lathe under $500 is a great tool for hobbyists. Knowing how to wire it correctly is essential for safety and efficiency. Readers will discover how to read a wiring diagram clearly. They will learn about wire connections, power supply requirements, and troubleshooting common issues. Did you know a poorly wired lathe can cause damage or accidents? Understanding this wiring can help prevent that and make your work smoother and more enjoyable!Understanding Metal Lathe Basics

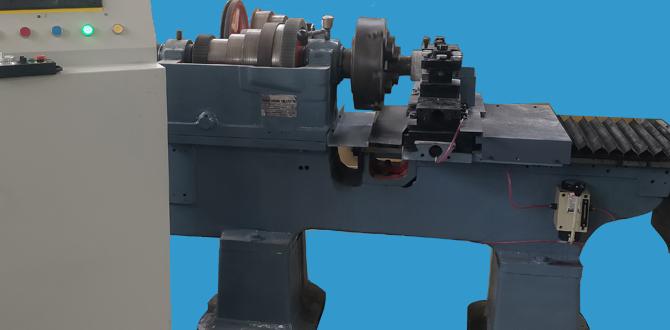

Explanation of what a metal lathe is and its functions. Importance of proper wiring for efficiency and safety.A metal lathe is a machine that shapes metal into different forms. It spins metal pieces, allowing tools to cut, carve, or polish them. This makes it very useful for creating parts for machines or tools.

Proper wiring is very important for a metal lathe. Good wiring ensures the machine runs smoothly and safely. Without it, there is a risk of accidents or malfunctions. Always follow the correct wiring diagrams to stay safe and efficient.

Why is proper wiring important for metal lathes?

Proper wiring is crucial for safety and performance. Correct wiring helps the machine work as it should and reduces the risk of electrical hazards. A properly wired metal lathe ensures a longer lifespan and better results.

- Improved efficiency

- Reduced risk of accidents

- Longevity of the machine

Choosing the Right Metal Lathe Under $500

Key features to look for in budgetfriendly lathe models. Comparison of popular models and their wiring options.Finding a good metal lathe under $500 can be easy if you know what to look for. First, check for power and speed options. A good model should have a strong motor and different speeds. Next, see if it includes included accessories, like tools and chucks. Compare popular models:

- Model A: Great for beginners, easy wiring.

- Model B: Has advanced features, but tricky wiring.

- Model C: Affordable, and comes with many tools.

Make sure to understand their wiring options for safety and ease of use!

What key features are important for a budget lathe model?

Look for power, speed settings, and user-friendly design. These features help you work better and safer.

Step-by-Step Wiring Diagram for Under $500 Metal Lathes

Detailed diagram showcasing essential wiring connections. Explanation of wiring color codes and their functions.Wiring a metal lathe under $500 can seem tricky, but it’s really like a puzzle! Start by using the detailed diagram, which shows all the essential connections clearly. Colors mean things too! For example, red usually means power. Make sure connections match the color codes! If the wires look like spaghetti, don’t worry; your lathe will be purring like a kitten in no time. Check out the helpful table below for color meanings!

| Color | Function |

|---|---|

| Red | Power Supply |

| Black | Ground |

| Blue | Control Signal |

Safety Precautions when Wiring Your Metal Lathe

Important safety tips and required personal protective equipment (PPE). Common wiring mistakes to avoid.Wiring a metal lathe can be fun, but safety is very important. You need to wear proper personal protective equipment (PPE) like gloves, goggles, and a dust mask. Make sure your workspace is clean and free from clutter. Here are some common wiring mistakes to avoid:

- Not turning off the power supply.

- Using the wrong type of wires.

- Failing to secure connections properly.

Remember, safety first helps keep everyone safe while working on your lathe.

What are the essential PPE items for wiring?

Wear gloves to protect your hands and goggles for your eyes. A dust mask can help you avoid inhaling dust. These items keep you safe while you work. Always prioritize your safety.

Common Wiring Issues and Troubleshooting Tips

Identification of potential wiring problems and their causes. Solutions and fixes for frequent electrical issues in metal lathes.Wiring problems can be a real pain, like trying to untangle your earbuds. Common issues include faulty connections and frayed wires. These can make your metal lathe act up, sparking like it’s auditioning for a firework show. Always check for loose wires, as they can cause machines to stop working suddenly. If your tool won’t start, it might just be a blown fuse, so check that first! Here are some quick fixes:

| Issue | Cause | Solution |

|---|---|---|

| Machine won’t start | Blown fuse | Replace the fuse |

| Intermittent power | Loose wire | Tighten connections |

| Unexpected shutdown | Overheating | Check ventilation |

Keep these tips handy, and you’ll handle metal lathe electrical issues like a pro. Remember, fixing wiring is like a game of connect-the-dots; you just have to find the right connections!

Maintaining Your Lathe’s Wiring System

Best practices for regular inspection and maintenance of wiring. Advice on upgrading components for enhanced performance.Checking your lathe’s wiring often keeps it safe and working well. Look for signs of wear, such as frayed wires. Regular checks can prevent big problems later. Upgrading some parts can help your lathe run smoother. Consider these tips:

- Inspect wiring every month.

- Replace old connectors for safety.

- Use high-quality tools for upgrades.

These practices help your lathe last longer and perform better. Remember, a little care goes a long way!

How often should I check my lathe’s wiring?

You should check your lathe’s wiring every month. Regular checks keep everything safe and in good shape!

Resources and Further Reading

Recommended books, websites, and videos on metal lathe wiring. Online forums and communities for metalworking enthusiasts.For those eager to learn more about metal lathe wiring, there are many great resources available. Consider exploring the following:

- Books: “The Metal Lathe” by Tom McIntosh is a good start.

- Websites: Check out Metalworking Fun for projects and tips.

- Videos: YouTube has channels like This Old Tony that offer hands-on guidance.

- Forums: Join communities like Practical Machinist for advice and support.

Exploring these resources can make learning about your under $500 metal lathe wiring diagram easier and more fun!

What are some recommended books on metal lathe wiring?

Some excellent books are “The Metal Lathe” by Tom McIntosh and “Lathework: A Complete Guide” by Andrew Walker. Both books cover essential topics.

Conclusion

In summary, finding an under $500 metal lathe wiring diagram helps you understand how to connect your machine safely. It’s essential for beginners and experienced users alike. By following clear steps, you can avoid mistakes. We encourage you to explore more resources online to deepen your knowledge and ensure successful projects. Happy wiring!FAQs

Here Are Five Related Questions On The Topic Of Wiring Diagrams For Metal Lathes Under $500:Wiring diagrams help us see how to connect parts of a metal lathe. They show which wires go where. If you have a metal lathe under $500, these diagrams can be very helpful. You can find free diagrams online or in manuals. Make sure to follow them carefully so everything works safely!

Of course! Please provide the question you’d like me to answer.

What Are The Essential Components Involved In Wiring A Budget-Friendly Metal Lathe?To wire a budget-friendly metal lathe, you need a few key parts. First, get a good power supply to provide electricity. Next, you will need a motor to make it move. Then, add switches to control when it starts and stops. Finally, use wires to connect everything safely. Make sure your connections are tight and secure!

How Do I Determine The Correct Power Supply For My Metal Lathe Under $500?To find the right power supply for your metal lathe, first, check the lathe’s power needs. Look for information about voltage and amps (a measure of electrical strength). You can usually find this in the manual or online. Then, compare this with power supplies available under $500. Make sure the supply matches what your lathe needs to work properly.

Are There Any Safety Precautions I Should Consider When Wiring A Metal Lathe?Yes, there are safety precautions to think about when wiring a metal lathe. Always turn off the power before you start working. Use gloves to protect your hands from sharp wires. Make sure you use the right tools to avoid accidents. Keep your area clean and free of clutter so you can move safely.

Can I Use A Generic Wiring Diagram For Different Models Of Metal Lathes, Or Do I Need A Specific Diagram For My Lathe?You should use a specific wiring diagram for your metal lathe. Each model can be different. A generic diagram may not fit your lathe. It’s safer and better to find the right one. This helps keep everything working well and safe.

What Common Wiring Mistakes Should I Avoid When Setting Up A Metal Lathe Under $500?When setting up your metal lathe, avoid using the wrong wires. Make sure the wires are thick enough for the machine. Don’t connect the wires in a messy way. This can cause problems or even a fire! Always double-check the connections before you turn it on.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Wiring Diagrams For Metal Lathes Under $500:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Wiring diagrams help us see how to connect parts of a metal lathe. They show which wires go where. If you have a metal lathe under $500, these diagrams can be very helpful. You can find free diagrams online or in manuals. Make sure to follow them carefully so everything works safely!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Involved In Wiring A Budget-Friendly Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a budget-friendly metal lathe, you need a few key parts. First, get a good power supply to provide electricity. Next, you will need a motor to make it move. Then, add switches to control when it starts and stops. Finally, use wires to connect everything safely. Make sure your connections are tight and secure!”}},{“@type”: “Question”,”name”: “How Do I Determine The Correct Power Supply For My Metal Lathe Under $500?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right power supply for your metal lathe, first, check the lathe’s power needs. Look for information about voltage and amps (a measure of electrical strength). You can usually find this in the manual or online. Then, compare this with power supplies available under $500. Make sure the supply matches what your lathe needs to work properly.”}},{“@type”: “Question”,”name”: “Are There Any Safety Precautions I Should Consider When Wiring A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are safety precautions to think about when wiring a metal lathe. Always turn off the power before you start working. Use gloves to protect your hands from sharp wires. Make sure you use the right tools to avoid accidents. Keep your area clean and free of clutter so you can move safely.”}},{“@type”: “Question”,”name”: “Can I Use A Generic Wiring Diagram For Different Models Of Metal Lathes, Or Do I Need A Specific Diagram For My Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use a specific wiring diagram for your metal lathe. Each model can be different. A generic diagram may not fit your lathe. It’s safer and better to find the right one. This helps keep everything working well and safe.”}},{“@type”: “Question”,”name”: “What Common Wiring Mistakes Should I Avoid When Setting Up A Metal Lathe Under $500?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up your metal lathe, avoid using the wrong wires. Make sure the wires are thick enough for the machine. Don’t connect the wires in a messy way. This can cause problems or even a fire! Always double-check the connections before you turn it on.”}}]}