Variable Speed Metal Lathe Cnc Retrofit Solutions Explained

Variable Speed Metal Lathe CNC Retrofit

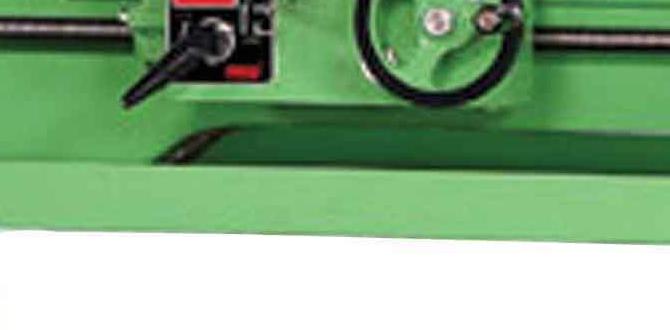

Imagine turning your old metal lathe into a modern CNC machine. With a **variable speed metal lathe CNC retrofit**, you can. This upgrade enhances precision and control. It allows for various speed settings to suit different materials. Did you know retrofitting can improve productivity and reduce waste? By adding CNC capabilities, you not only save time but also achieve better results. This transformation opens new possibilities for hobbyists and professionals alike. Why not consider a retrofit for your shop?Understanding Variable Speed Metal Lathes

Definition and purpose of variable speed metal lathes. Advantages of variable speed control in machining.Variable speed metal lathes are machines used to shape metal parts. They can change their spinning speed based on the task. This flexibility helps workers make precise cuts. With variable speed control, machinists can:

- Adjust speed for soft or hard materials

- Improve surface finish on parts

- Increase tool life by minimizing wear

The result? Better quality work done faster. It’s like having the right gear for every job!

What benefits come from variable speed control?

It gives better control and accuracy, making tasks more efficient and saving time.Key Components of a CNC Retrofit Kit

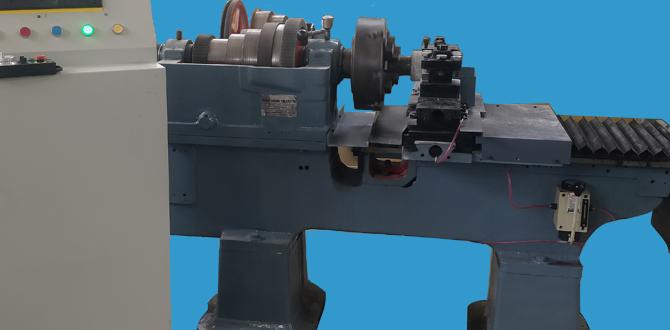

Essential parts for a successful CNC retrofit. Discussing servo motors, controllers, and software.A CNC retrofit kit helps turn regular machines into smart ones. Key parts make this happen. First, servo motors drive the machine precision. They are fast and efficient. Next, controllers manage commands for the machine. They ensure everything works smoothly. Lastly, software gives instructions. It lets users design and adjust projects easily. Together, these components create a powerful system for metal lathes.

What are the main parts of a CNC retrofit kit?

The main parts are servo motors, controllers, and software.Key Components:

- Servo motors: Provide power and speed.

- Controllers: Manage the machine’s movements.

- Software: Helps design and run projects.

Benefits of Retrofitting a Metal Lathe

Enhanced precision and repeatability of operations. Costeffectiveness compared to purchasing new CNC machines.Retrofitting a metal lathe is like giving your old machine a fancy upgrade! You’ll notice sharper cuts with enhanced precision, which means better work every time. Plus, it keeps things consistent, so you can reproduce the same high-quality piece again and again. Who wouldn’t want that? Best of all, it’s often much cheaper than splurging on brand-new CNC machines. Your wallet will thank you, and your metal lathe may just do a little happy dance!

| Benefits | Details |

|---|---|

| Enhanced Precision | Sharper cuts for better quality work. |

| Cost-Effectiveness | Cheaper than buying new CNC machines. |

Step-by-Step Retrofits for Variable Speed Metal Lathes

Detailed process for retrofitting, from planning to execution. Tools and materials needed for a successful retrofit.Upgrading your lathe is like giving it a shiny new pair of shoes! Start by planning your retrofit. Make a list of what you need, including parts like a motor, controllers, and essential tools. For a smooth process, gather items like wrenches and screwdrivers. Below is a handy table of tools and materials:

| Tools | Materials |

|---|---|

| Wrenches | New Motor |

| Screwdrivers | CNC Controller |

| Multimeter | Wiring Kit |

Once you gather everything, it’s time to get to work! Follow each step carefully, like a recipe for a cake. Remember, a successful retrofit means you can make things spin faster and smoother, just like a rollercoaster ride. Enjoy the process!

Common Challenges and Solutions in CNC Retrofitting

Identifying potential pitfalls during the retrofit process. Effective troubleshooting methods and preventative measures.Retrofitting a CNC machine can feel like trying to teach a cat to fetch. You might face a few bumps along the way. One common pitfall is overlooking the machine’s compatibility with new parts. Always check if your lathe can handle those shiny upgrades. Troubleshooting might seem tricky, but think of it like a treasure hunt. Use simple checks to find issues, like ensuring all connections are snug. Preventative measures? Keep a toolkit handy—like a superhero with a utility belt!

| Common Problems | Possible Solutions |

|---|---|

| Incompatibility | Research part specifications before purchase. |

| Electrical issues | Check wiring and connections. |

| Software glitches | Update software regularly and read the manual. |

Remember, retrofitting brings new life to your lathe, and with the right approach, you can dance through the process like a pro!

Choosing the Right Retrofit Solution for Your Needs

Factors to consider when selecting a retrofit kit. Recommendations for reputable suppliers and brands.Choosing a retrofit kit is an important decision. Keep these factors in mind:

- Compatibility: Will it fit your current machine?

- Ease of Installation: Can you install it without help?

- Budget: Does it fit your wallet?

- Features: Does it have the tools you need?

For reliable suppliers, consider brands like Haas, Grizzly, or Tormach. They are known for quality parts and support.

What should I look for in a retrofit kit?

Look for quality, support, and features. Make sure it fits your needs and your machine.

Finding the right solution can make or break your project. Ask yourself these questions and do some research to help narrow your choices.

Success Stories: Case Studies of CNC Retrofitting

Realworld examples of businesses benefiting from metal lathe retrofitting. Analysis of improvements in productivity and efficiency.Many businesses have seen great results from retrofitting their metal lathes. For example, a small machine shop upgraded to a CNC system and improved their production speed by 40%. They could now make parts faster and with better quality. Another case showed an increase in efficiency by 30% after adding a variable speed feature. This meant less downtime and more profits. Here are some quick highlights:

- Increased Speed: Shops often report up to a 50% boost.

- Better Accuracy: Upgrading led to a 25% drop in mistakes.

- Cost Savings: One business saved $10,000 a year in material waste.

What are the benefits of CNC retrofitting?

The main benefits include improved speed, accuracy, and cost savings. These improvements can lead to higher profits for businesses. Keeping machines up-to-date is key for success.

Future Trends in CNC Technology and Retrofits

Innovations shaping the future of CNC lathes. Predictions for variable speed technology advancements.New technology is changing CNC machining fast. Exciting innovations are making CNC lathes smarter and faster. Variable speed control is one key area. This allows machines to adjust speed for different materials. With this, we can expect:

- Improved energy efficiency

- Greater precision in cutting

- More user-friendly interfaces

By 2030, experts believe variable speed technology will get even better. Machines will adapt on their own, making work easier. This means fewer mistakes and more amazing products.

What are future trends in CNC technology?

Future CNC technology will focus on automation and data integration. These will allow machines to work more efficiently and connect better with networks.

Conclusion

In conclusion, retrofitting a variable speed metal lathe with CNC adds precision and flexibility. This upgrade allows you to create complex designs easily. You can boost your skills and productivity with this technology. If you’re interested, dive deeper into CNC resources online or connect with local workshops. Take the next step to enhance your metalworking journey today!FAQs

What Are The Key Components Needed For Retrofitting A Traditional Metal Lathe With Cnc Capabilities?To retrofit a traditional metal lathe with Computer Numerical Control (CNC), you need a few important parts. First, you need a motor to move the lathe automatically. Next, you need a control board to tell the lathe what to do. You also need software to create the designs you want to cut. Finally, don’t forget sensors to help with precision and accuracy.

How Does A Variable Speed Drive Enhance The Functionality Of A Cnc Retrofitted Lathe Compared To A Standard Lathe?A variable speed drive lets you change the speed of the lathe easily. This means you can work on different materials better. You can go fast for soft materials and slow for hard ones. This change helps you make precise cuts and improves your work. Overall, it makes using the lathe easier and more fun!

What Are The Common Challenges Faced During The Cnc Retrofit Process Of A Metal Lathe, And How Can They Be Overcome?During the CNC (Computer Numerical Control) retrofit process of a metal lathe, you might face a few challenges. First, fitting new parts can be tricky. To fix this, we should carefully measure and plan. Second, learning to use new software can be hard. You can overcome this by practicing and using tutorials. Finally, you may need special tools or help, so asking experts can make things easier.

Which Control Software Is Most Compatible With Cnc Retrofitted Metal Lathes, And What Features Should It Support?One popular control software for CNC retrofitted metal lathes is GRBL. It is free and easy to use. This software should support features like moving the machine, setting limits, and controlling speed. You want it to help you make precise cuts and shapes. With the right software, you can turn ideas into real projects!

How Can One Determine The Appropriate Motor Size And Type For A Cnc Retrofit Of A Variable Speed Metal Lathe?To pick the right motor for a CNC retrofit on a metal lathe, you need to think about a few things. First, check the size of your lathe and how much power it needs. You can find this in the lathe’s manual or by asking experts. Next, decide if you want a stepper motor or a servo motor, which helps with speed and control. Finally, make sure the motor works well with your CNC system for smooth operation.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Needed For Retrofitting A Traditional Metal Lathe With Cnc Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To retrofit a traditional metal lathe with Computer Numerical Control (CNC), you need a few important parts. First, you need a motor to move the lathe automatically. Next, you need a control board to tell the lathe what to do. You also need software to create the designs you want to cut. Finally, don’t forget sensors to help with precision and accuracy.”}},{“@type”: “Question”,”name”: “How Does A Variable Speed Drive Enhance The Functionality Of A Cnc Retrofitted Lathe Compared To A Standard Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A variable speed drive lets you change the speed of the lathe easily. This means you can work on different materials better. You can go fast for soft materials and slow for hard ones. This change helps you make precise cuts and improves your work. Overall, it makes using the lathe easier and more fun!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During The Cnc Retrofit Process Of A Metal Lathe, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “During the CNC (Computer Numerical Control) retrofit process of a metal lathe, you might face a few challenges. First, fitting new parts can be tricky. To fix this, we should carefully measure and plan. Second, learning to use new software can be hard. You can overcome this by practicing and using tutorials. Finally, you may need special tools or help, so asking experts can make things easier.”}},{“@type”: “Question”,”name”: “Which Control Software Is Most Compatible With Cnc Retrofitted Metal Lathes, And What Features Should It Support? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “One popular control software for CNC retrofitted metal lathes is GRBL. It is free and easy to use. This software should support features like moving the machine, setting limits, and controlling speed. You want it to help you make precise cuts and shapes. With the right software, you can turn ideas into real projects!”}},{“@type”: “Question”,”name”: “How Can One Determine The Appropriate Motor Size And Type For A Cnc Retrofit Of A Variable Speed Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right motor for a CNC retrofit on a metal lathe, you need to think about a few things. First, check the size of your lathe and how much power it needs. You can find this in the lathe’s manual or by asking experts. Next, decide if you want a stepper motor or a servo motor, which helps with speed and control. Finally, make sure the motor works well with your CNC system for smooth operation.”}}]}