Have you ever wondered how machines like lathes work? A variable speed metal lathe is a fascinating tool that helps create many metal objects we see every day. But there’s one feature that many people overlook: the foot brake. Why is this foot brake so important?

Imagine you’re working on a project. You’re focused, and everything is going well. Suddenly, you need to stop quickly. That’s where the foot brake comes in! It allows you to stop the lathe safely and quickly without losing control.

Did you know that controlling the speed of the lathe is key to making precise cuts? The variable speed feature helps you adjust how fast or slow the lathe spins. Pair that with a reliable foot brake, and you have a powerful tool that’s easy to manage. Isn’t that neat?

In this article, we’ll explore how a variable speed metal lathe foot brake works. You’ll learn why it matters and how it improves safety and efficiency in metalworking. Let’s dive in together!

Variable Speed Metal Lathe Foot Brake: Enhance Precision & Safety

Understanding Variable Speed Metal Lathe Foot Brake

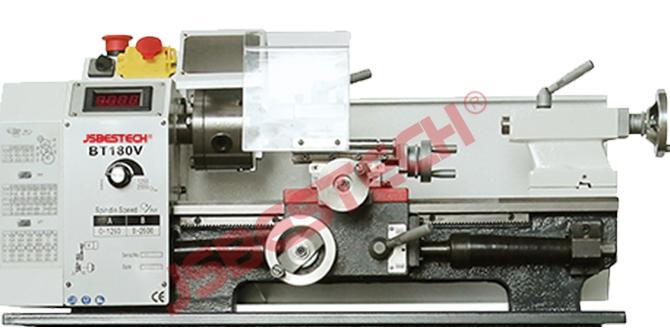

Variable speed metal lathes come with a crucial feature: the foot brake. This handy tool lets you stop the machine quickly and safely, which is vital in workshops. Imagine you’re working on a project, and suddenly you need to halt the lathe—this brake is your best friend. It helps prevent accidents and offers better control. Plus, having a foot-operated brake keeps your hands free for other tasks. Stay safe and efficient while working with a variable speed lathe!Understanding Variable Speed Metal Lathes

Definition and key features of variable speed metal lathes. Importance of speed control in machining processes.A variable speed metal lathe is a special tool that helps shape metal by spinning it around. Unlike regular lathes, these models can change speed easily. This feature is cool because it lets you work with different materials and get the job done better. Speed control is key because it makes the machining process smoother and safer. After all, nobody wants a surprise metal shower! It’s like changing gears while riding a bike – you need the right speed to avoid falling over!

| Feature | Importance |

|---|---|

| Variable Speed Control | Allows for precision in metal shaping. |

| Easy Adjustments | Enhances safety and efficiency. |

The Role of Foot Brakes in Metal Lathes

Explanation of foot brake functionality in metal lathes. Advantages of using a foot brake for operator safety and efficiency.Foot brakes play a key role in metal lathes, acting like a superhero for operators. They help stop the machine quickly. This safety feature ensures that if something goes wrong, the operator can react fast and avoid accidents. Plus, foot brakes make work smoother. Imagine trying to switch off a lathe with your hands! It’s a bit like playing tag with a slippery fish—fun but tricky!

| Advantages of Foot Brakes | Explanation |

|---|---|

| Safety | Quick stops prevent accidents. |

| Efficiency | Hands-free operation means faster work. |

In short, using a foot brake is smart. It keeps everyone safe and boosts productivity. Let’s give a high-five to foot brakes for making metal working safer and more fun!

Types of Foot Brakes for Metal Lathes

Pneumatic vs. hydraulic foot brakes: differences and applications. Electric foot brakes and their benefits.Foot brakes for metal lathes come in different types, each with unique features. Pneumatic brakes use air pressure. They are fast and responsive, making them great for quick stops. Hydraulic brakes use fluid. They provide strong stopping power but can be slower. Then we have electric foot brakes. These brakes are efficient and easy to use. They allow for smooth stopping and are often quieter. Each type can fit various projects based on speed and precision needed.

What are the main differences between pneumatic and hydraulic foot brakes?

Pneumatic brakes are quick and great for fast stops. Hydraulic brakes offer strong, steady stops. Choose based on your task!

Benefits of electric foot brakes

- Easy to control

- Quieter operation

- Reliable performance

Installation and Configuration of Foot Brakes

Stepbystep guide on installing a foot brake on a metal lathe. Adjusting brake settings for optimal performance.Installing a foot brake on your metal lathe can be a simple task if you follow a few steps. First, gather your tools and read the instructions carefully—yes, even those tiny ones! Attach the brake assembly securely. Make sure it fits snugly; we don’t want it flying off during use! Next, connect wires carefully without mixing colors, unless you want an unexpected light show. After installation, adjust the brake settings. This ensures your lathe stops safely and reliably. A calm lathe is a happy lathe!

| Step | Action |

|---|---|

| 1 | Read the instructions |

| 2 | Attach the brake assembly |

| 3 | Connect the wiring |

| 4 | Adjust the brake settings |

For optimal performance, check the settings regularly. That way, you keep your work area safe and sound! Remember, a properly set brake can save you from unexpected surprises. And nobody likes surprise parties, especially when they involve flying parts!

Maintenance Tips for Foot Brakes

Regular maintenance checks to prolong brake life. Common issues and troubleshooting advice.To keep your foot brake in top shape, regular maintenance is key. A quick check every few months can help find problems early. Look for bad connections or worn parts. If you hear strange noises, it’s time to take action. This can prevent bigger issues down the line.

- Inspect the brake every 3 months.

- Check wiring for damage.

- Look for any rust or wear on parts.

- Listen for unusual sounds while using the brake.

Simple steps can extend the life of your brake. This prevents the need for costly repairs and keeps you safe.

What are common issues with foot brakes?

Common issues with foot brakes include frayed wires and loose connections. These problems can make the brake less effective. Regular checks help catch issues early.

Safety Precautions When Using Foot Brakes

Essential safety measures to consider while operating lathes. Potential hazards and how to prevent accidents.Using foot brakes on lathes can be safe if you follow a few simple rules. Always wear protective gear like goggles to guard your eyes. Ensure your area is clean to avoid slips. Be aware of loose clothing and hair, as they can get caught in the machine. Here are some key safety points:

- Keep guards in place.

- Do not reach into the machine while it is running.

- Use the brake correctly to stop the lathe.

- Turn off the machine before making adjustments.

By staying alert and prepared, you can prevent accidents and work safely!

What should I do if something goes wrong with the lathe?

If something goes wrong, turn off the machine immediately and check for the problem.Comparative Analysis: Foot Brakes vs. Manual Controls

Pros and cons of using foot brakes compared to manual controls. Impact on productivity and operator comfort.Both foot brakes and manual controls have their own strengths and weaknesses. Foot brakes offer easy access, allowing quick stops without using hands. This setup helps workers stay focused. On the flip side, manual controls might give more precise speed adjustments but can slow things down. Here’s a quick comparison:

- Foot Brakes: Faster stopping, easier multitasking, safer handling.

- Manual Controls: More precise adjustments, better for delicate tasks, can be cumbersome.

Using foot brakes can boost productivity and make work more comfortable. In fact, workers report feeling less tired after long hours. Comfort leads to better focus, which can increase output.

What are the benefits of foot brakes?

The best part about foot brakes is they allow quick stopping and improve overall efficiency. This makes them great for busy shops!

Customer Reviews and Case Studies

Feedback from operators about their experiences with foot brakes. Case studies showcasing the benefits of foot brakes in various applications.Operators have shared many positive experiences with foot brakes. They appreciate how fast they can stop their lathes. This feature makes their work safer and more efficient. Many users reported smoother transitions and better control, leading to high-quality work.

- Increased safety during operations.

- Improved accuracy in tasks.

- Reduced wear on machinery.

- Enhanced user confidence and comfort.

Case studies show that foot brakes help in various applications. For example, a metal shop saw a 30% increase in productivity after adding this feature. Operators stated they felt more in control and could respond quickly to changes.

What are the benefits of foot brakes in metal lathes?

Foot brakes improve safety, control, and productivity for operators. They make work smoother and cut down on mistakes. This can lead to better outcomes in projects.

Future Trends in Metal Lathe Technology

Emerging technologies in variable speed metal lathes and braking systems. Predictions for the future of safety and efficiency in machining.Metal lathe technology is changing fast! New features in variable speed lathes are making them smarter and safer. For example, advanced braking systems can stop machines quicker than a superhero in a hurry. Experts predict that these lathes will get even better. Increased focus on safety means fewer accidents and more efficiency in workshops. Soon, we might even see lathes that talk back—don’t worry, they won’t ask for lunch breaks!

| Emerging Technologies | Predicted Benefits |

|---|---|

| Smart braking systems | Improved safety and quick stops |

| AI integration | More efficient machining processes |

| Remote monitoring | Less downtime for repairs |

Conclusion

In summary, a variable speed metal lathe foot brake is important for safety and control. It allows you to stop quickly while working. This feature improves your precision and prevents accidents. We encourage you to explore different lathes and their brakes. Try hands-on practice or read more about them online. Understanding this tool can make you a better metalworker!FAQs

Certainly! Here Are Five Questions Related To The Variable Speed Metal Lathe Foot Brake:Sure! A variable speed metal lathe is a machine that spins metal to shape it. The foot brake helps you stop the machine quickly when you need to. You use your foot to press the brake, just like stopping a car. This way, you can work safely without getting hurt. It’s important for keeping things under control!

Sure! Please share the question you want me to answer, and I’ll be happy to help!

What Is The Primary Function Of A Foot Brake On A Variable Speed Metal Lathe, And How Does It Enhance Operator Safety?The foot brake on a variable speed metal lathe helps you stop the machine quickly. When you press it, the machine slows down fast. This is important for keeping you safe while you work. It prevents accidents and lets you react quickly if something goes wrong.

How Does The Design Of A Foot Brake Differ Between Manual And Cnc Variable Speed Metal Lathes?The foot brake on a manual lathe is often simple. You press it to stop the machine quickly. In contrast, a CNC (Computer Numerical Control) lathe has a more advanced brake system. It can help control the machine more smoothly and safely. So, the design is different to match how each lathe works.

What Maintenance Procedures Are Recommended To Ensure The Foot Brake On A Variable Speed Metal Lathe Operates Effectively?To keep the foot brake on a metal lathe working well, you should check it often. Make sure it is clean and free of dust. You can oil the moving parts if they seem stiff. Test the brake regularly to ensure it stops the lathe quickly. If it doesn’t work like it should, ask an adult for help!

How Does The Integration Of An Electronic Control System Impact The Performance Of The Foot Brake On A Variable Speed Metal Lathe?An electronic control system helps the foot brake work better on a metal lathe. It makes the brake stop the machine quickly and safely. You can control the speed more easily with this system. This means less chance of accidents and better results in your work. Overall, it makes the lathe easier and safer to use.

What Are The Potential Risks Associated With A Malfunctioning Foot Brake On A Variable Speed Metal Lathe, And How Can They Be Mitigated?A broken foot brake on a metal lathe can be very dangerous. You might lose control of the machine, which can cause accidents. Tools could fly off or the machine might keep spinning when you want to stop. To stay safe, always check the brake before using the lathe. If you see any problems, get it fixed right away.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To The Variable Speed Metal Lathe Foot Brake:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A variable speed metal lathe is a machine that spins metal to shape it. The foot brake helps you stop the machine quickly when you need to. You use your foot to press the brake, just like stopping a car. This way, you can work safely without getting hurt. It’s important for keeping things under control!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Foot Brake On A Variable Speed Metal Lathe, And How Does It Enhance Operator Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The foot brake on a variable speed metal lathe helps you stop the machine quickly. When you press it, the machine slows down fast. This is important for keeping you safe while you work. It prevents accidents and lets you react quickly if something goes wrong.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Foot Brake Differ Between Manual And Cnc Variable Speed Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The foot brake on a manual lathe is often simple. You press it to stop the machine quickly. In contrast, a CNC (Computer Numerical Control) lathe has a more advanced brake system. It can help control the machine more smoothly and safely. So, the design is different to match how each lathe works.”}},{“@type”: “Question”,”name”: “What Maintenance Procedures Are Recommended To Ensure The Foot Brake On A Variable Speed Metal Lathe Operates Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake on a metal lathe working well, you should check it often. Make sure it is clean and free of dust. You can oil the moving parts if they seem stiff. Test the brake regularly to ensure it stops the lathe quickly. If it doesn’t work like it should, ask an adult for help!”}},{“@type”: “Question”,”name”: “How Does The Integration Of An Electronic Control System Impact The Performance Of The Foot Brake On A Variable Speed Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “An electronic control system helps the foot brake work better on a metal lathe. It makes the brake stop the machine quickly and safely. You can control the speed more easily with this system. This means less chance of accidents and better results in your work. Overall, it makes the lathe easier and safer to use.”}},{“@type”: “Question”,”name”: “What Are The Potential Risks Associated With A Malfunctioning Foot Brake On A Variable Speed Metal Lathe, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A broken foot brake on a metal lathe can be very dangerous. You might lose control of the machine, which can cause accidents. Tools could fly off or the machine might keep spinning when you want to stop. To stay safe, always check the brake before using the lathe. If you see any problems, get it fixed right away.”}}]}