Have you ever wondered how metal parts are shaped with such precision? One key tool that makes this possible is the variable speed metal lathe. It’s a machine that can spin metal quickly, allowing experts to cut and shape it just right.

Imagine a metal lathe as a giant spinning top. Just like how you can control the speed of the top, a variable speed lathe lets you change its speed. This is super important because different projects need different speeds. Some tasks require slow and steady work, while others need fast action.

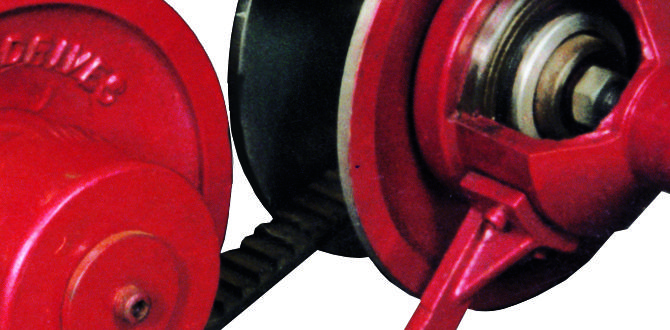

Did you know that the pulley system on these lathes plays a big role? It helps keep everything running smoothly. With the right pulley setup, you can easily switch speeds and tackle different tasks. Isn’t that neat?

In this article, we will explore the workings of a variable speed metal lathe pulley. You’ll discover tips and tricks to make your projects easier and more fun. Whether you’re a beginner or an expert, there’s something here for everyone!

Understanding Variable Speed Metal Lathe Pulley Systems

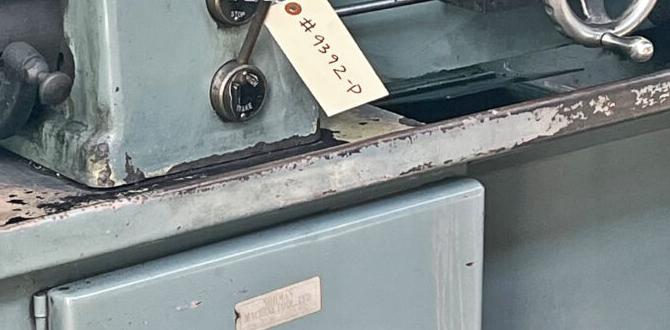

Variable Speed Metal Lathe Pulley

Understanding a variable speed metal lathe pulley is crucial for anyone keen on metalworking. This system allows users to control the speed of the lathe with ease. Have you ever wished for smoother cuts or simpler adjustments? With variable speed, you can achieve just that. Fun fact: a lathe has been used since ancient times, making it a staple in workshops today. Explore how this technology enhances precision and efficiency in metal projects!What is a Variable Speed Metal Lathe Pulley?

Definition and function of a variable speed lathe pulley.. Importance in metalworking and machining..A variable speed metal lathe pulley is a special tool used in metalworking. It helps control the speed of a lathe, which is a machine that shapes metal. The main function of this pulley is to change how fast or slow the lathe spins. This can improve the quality of the work. By adjusting the speed, workers can create better pieces and avoid mistakes.

The importance of this pulley in machining includes:

- Greater control: Operators can fine-tune the speed easily.

- Better finishes: Different speeds give different results.

- Safety: Slower speeds help prevent accidents.

In metalworking, using the right speed can make all the difference!

Why are variable speed metal lathe pulleys important?

They offer precision and flexibility, allowing metalworkers to achieve high-quality results.

Benefits of Using Variable Speed Metal Lathe Pulleys

Enhanced control over cutting speeds for improved precision.. Reduction in tool wear and extended lifespan of equipment..Using a variable speed metal lathe pulley makes working with your lathe much easier and more fun! It gives you better control over cutting speeds, meaning you can shape your metal just the way you want. This leads to improved precision and less guesswork. Plus, since you can adjust speeds, it reduces wear on your tools. Your equipment can last longer, which means more projects and fewer problems. And who wouldn’t want to keep their tools happy?

| Benefit | Description |

|---|---|

| Enhanced Control | Allows you to choose the perfect speed for each job. |

| Less Tool Wear | Reduces stress on tools, making them last longer. |

How to Choose the Right Variable Speed Metal Lathe Pulley?

Factors to consider: size, material, and compatibility.. Understanding the specifications and their impact on performance..Choosing the right variable speed metal lathe pulley is important for good performance. You should think about a few key factors. First, check the size. Make sure it fits your lathe. Next, look at the material. Good materials last longer and handle stress better. Finally, consider compatibility. Your pulley must work well with your machine. Understanding these specs will help you make the best choice.

- Size: Ensure a proper fit.

- Material: Choose durable options.

- Compatibility: Ensure it matches your lathe model.

What should I consider when choosing a variable speed metal lathe pulley?

Consider size, material, and compatibility. Each factor greatly affects how well your lathe operates. A well-chosen pulley can enhance your work quality.

Installation and Maintenance of Variable Speed Metal Lathe Pulleys

Stepbystep guide to installation for optimal performance.. Maintenance tips to ensure longevity and prevent wear..Setting up your variable speed metal lathe pulley can be as fun as building with blocks! First, turn off the machine and unplug it—safety first, right? Next, check the installation manual for how to position the pulley. Stick to the guidelines for optimal performance! Use the right tools and secure it tightly. Now, let’s talk about keeping it happy! Regularly clean it and check for any wear. A little maintenance goes a long way, like brushing your teeth! As they say, “A lazy pulley is a squeaky pulley!”

| Tip | Description |

|---|---|

| Safety Check | Always switch off and unplug before starting. |

| Installation Guide | Follow the manual for secure placement. |

| Regular Cleaning | Keep it dust-free to extend its life. |

| Wear Inspection | Look for signs of wear to prevent problems. |

Common Issues with Variable Speed Metal Lathe Pulleys

Identifying common problems such as slipping and noise.. Troubleshooting tips and solutions for maintenance..Metal lathe pulleys can sometimes play tricks on you! Common problems include slipping belts and annoying noise. If your pulley starts to slip, it may be a little too loose or even damaged. Give it a checkup! Regular maintenance can prevent a lot of headaches. Tightening belts and greasing parts can work wonders. And if you hear strange sounds, it might be time to let your lathe see a doctor – or a mechanic! Below are some tips:

| Issue | Solution |

|---|---|

| Slipping Belt | Tighten or replace the belt. |

| Unusual Noise | Check for loose parts or apply lubricant. |

Keep your lathe healthy and it will work like a charm! Remember, a happy lathe is a productive lathe!

Comparing Fixed and Variable Speed Lathe Systems

Key differences between fixed and variable speed options.. Pros and cons of each system in various applications..Fixed and variable speed lathes work differently. A fixed speed lathe has one speed, while a variable speed lathe can change speeds. Here are some points to consider:

- Fixed Speed: Simple and easy to use. Best for consistent tasks. However, it can limit versatility.

- Variable Speed: Offers flexibility. Perfect for different materials. But, it may be more complex and costly.

Different tasks may need one system over the other. For example, woodworking might prefer fixed, while machining could benefit from variable speed options. Think about your needs before choosing!

What are the advantages of variable speed lathes?

Variable speed lathes provide flexibility in speed adjustments. This allows for better control during various operations, making them suitable for a range of materials and tasks.

Future Trends in Variable Speed Metal Lathe Technology

Innovations and advancements on the horizon.. How technology is changing the landscape of metalworking equipment..New ideas in variable speed metal lathe technology are here. Engineers are making machines smarter. They are using sensors to improve safety and performance. Advanced software helps control speeds better. This means machines can work faster and with more accuracy. Soon we may see:

- Eco-friendly materials being used

- Automated systems for smoother operation

- More user-friendly designs for easy use

These breakthroughs change how metalworking tools work. Exciting times are ahead for builders and makers alike!

What are some future innovations in metal lathe technology?

Future innovations include smart sensors, automated features, and eco-friendly materials. These changes will improve speed, safety, and ease of use in metalworking.

Conclusion

In summary, a variable speed metal lathe pulley helps you control speed and improve your projects. It makes turning metal easier and more precise. We explored its benefits and how it works. Now, you can check your lathe for a pulley upgrade. Feel free to read more about lathes to enhance your skills and creativity!FAQs

Certainly! Here Are Five Questions Related To The Topic Of Variable Speed Metal Lathe Pulleys:Variable speed metal lathe pulleys help machines work at different speeds. You can change how fast the lathe spins. This helps when cutting metal shapes. Using pulleys makes it easier to get the right speed for your project. So, you can create better items!

Sure! Please provide the question you would like me to answer.

What Are The Advantages Of Using A Variable Speed Pulley System In A Metal Lathe Compared To A Fixed-Speed System?Using a variable speed pulley system in a metal lathe lets you change speeds easily. This means you can work on different types of metal better. You can turn faster for some tasks and slower for others, which helps make a better shape. It also saves energy and keeps the machine from getting too hot. This way, you get better results when making things!

How Do You Properly Adjust The Pulley System On A Variable Speed Metal Lathe To Achieve The Desired Spindle Speed?To adjust the pulley system on a variable speed lathe, first, turn off the machine. Look for the pulleys and follow the belt to the right spot. You can move the belt to a different pulley to change the speed. After moving it, turn the machine back on and check the speed. Keep adjusting until you get the speed you want.

What Maintenance Practices Are Recommended To Ensure Optimal Performance And Longevity Of Variable Speed Pulleys On Metal Lathes?To keep variable speed pulleys on metal lathes working well, you should check them often. Make sure they are clean and free from dust. Lubricate them with oil as needed to help them move smoothly. Also, look for any loose parts and tighten them. Doing these simple things will help your lathe last longer!

How Does The Design Of The Variable Speed Pulley Affect Torque Transmission And Overall Machining Efficiency On A Metal Lathe?The design of a variable speed pulley helps control how fast the metal lathe spins. When you change the speed, you also change the torque, which is the turning power. More torque means you can cut metal easier and faster. This makes your work more efficient, helping you finish tasks quicker. Good design keeps everything running smoothly, which helps you make better parts!

What Are The Common Signs Of Wear Or Failure In A Variable Speed Pulley System, And How Can They Be Addressed?In a variable speed pulley system, you might notice strange noises or vibrations. The pulley could look worn or have cracks. If you see these signs, you should check the belt for damage, too. To fix problems, you can tighten loose parts or replace worn-out pieces. Regularly checking the system helps catch issues early!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To The Topic Of Variable Speed Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed metal lathe pulleys help machines work at different speeds. You can change how fast the lathe spins. This helps when cutting metal shapes. Using pulleys makes it easier to get the right speed for your project. So, you can create better items!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Variable Speed Pulley System In A Metal Lathe Compared To A Fixed-Speed System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a variable speed pulley system in a metal lathe lets you change speeds easily. This means you can work on different types of metal better. You can turn faster for some tasks and slower for others, which helps make a better shape. It also saves energy and keeps the machine from getting too hot. This way, you get better results when making things!”}},{“@type”: “Question”,”name”: “How Do You Properly Adjust The Pulley System On A Variable Speed Metal Lathe To Achieve The Desired Spindle Speed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the pulley system on a variable speed lathe, first, turn off the machine. Look for the pulleys and follow the belt to the right spot. You can move the belt to a different pulley to change the speed. After moving it, turn the machine back on and check the speed. Keep adjusting until you get the speed you want.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended To Ensure Optimal Performance And Longevity Of Variable Speed Pulleys On Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep variable speed pulleys on metal lathes working well, you should check them often. Make sure they are clean and free from dust. Lubricate them with oil as needed to help them move smoothly. Also, look for any loose parts and tighten them. Doing these simple things will help your lathe last longer!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Variable Speed Pulley Affect Torque Transmission And Overall Machining Efficiency On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a variable speed pulley helps control how fast the metal lathe spins. When you change the speed, you also change the torque, which is the turning power. More torque means you can cut metal easier and faster. This makes your work more efficient, helping you finish tasks quicker. Good design keeps everything running smoothly, which helps you make better parts!”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Failure In A Variable Speed Pulley System, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a variable speed pulley system, you might notice strange noises or vibrations. The pulley could look worn or have cracks. If you see these signs, you should check the belt for damage, too. To fix problems, you can tighten loose parts or replace worn-out pieces. Regularly checking the system helps catch issues early!”}}]}