Have you ever watched a skilled craftsman work with a lathe? It’s fascinating to see how metal transforms into beautiful shapes and designs. But did you know that a variable speed metal lathe can make this process even easier? One key tool in this process is the threading dial.

The threading dial helps machinists create precise threads on metal pieces. This might sound complicated, but it’s crucial for making things like screws and bolts. Imagine a world where every piece fits perfectly! Isn’t it amazing how a small device can make such a big difference?

In this article, we will explore how a variable speed metal lathe threading dial works and why it’s so important. Are you curious about how these tools can change your projects? Let’s dive in and discover more!

Variable Speed Metal Lathe Threading Dial: A Comprehensive Guide

Understanding the Variable Speed Metal Lathe Threading Dial

The variable speed metal lathe threading dial helps hobbyists and professionals alike. It allows for precise adjustments while working on metal projects. Imagine making perfect threads every time; that’s what this tool offers! With its variable speed control, you can work at your own pace. Have you ever struggled with incorrect measurements? This dial helps eliminate that problem. It’s an essential tool for anyone who values accuracy and efficiency in their metalworking tasks.Understanding Variable Speed Metal Lathes

Definition and function of variable speed metal lathes. Advantages of using a variable speed lathe over traditional models.Variable speed metal lathes are machines that spin metal to shape it. They let you control the speed of the spinning, so you don’t have to go full throttle all the time. It’s like having a car with cruise control! This feature helps create more precise cuts and safer work. Compared to traditional lathes, variable speed models are often easier to use and more versatile. You can work on different types of projects without switching machines. So, if you want to impress your friends with your amazing metalworking skills, get one of these!

| Advantage | Description |

|---|---|

| Precision | Adjustable speed provides a more accurate finish. |

| Flexibility | Works great for various materials and projects. |

| Safety | Slower speeds mean less chance of accidents! |

Components of a Metal Lathe

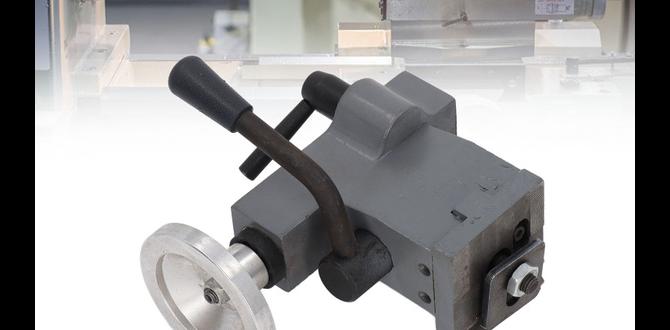

Key parts related to threading dials. Importance of precision in threading operations.The metal lathe is like a superhero in the workshop with a few key sidekicks that make it work wonders. One important part is the threading dial. This little dial helps create threads perfectly. Why is this important? Well, if you want your screws to fit just right, precision is a must! A wrong thread can make even a burrito fall apart. So, let’s appreciate this hero’s trusty helpers!

| Part | Importance |

|---|---|

| Threading Dial | Helps ensure accurate thread creation. |

| Chuck | Holds the workpiece firmly. |

| Tailstock | Supports tools for cutting precision. |

In the world of metal lathes, precision makes the difference between a masterpiece and a mishap!

How to Use a Threading Dial Effectively

Stepbystep guide on setting up the threading dial. Tips for accurate measurements and threading performance.Using the threading dial on your lathe can be a fun adventure! First, set the dial to zero before starting any threading. This gives you a clean slate. Next, carefully move the carriage to the desired starting point. Make sure you watch your measurements—like a hawk watching its prey! For precise results, align the dial with your spindle’s position and turn slowly. Remember, patience is key! A mistake? No worries—just try again. Practice makes perfect, after all. If only threading was as easy as slicing butter!

| Steps | Tips |

|---|---|

| Set the dial to zero | Always check for alignment |

| Move the carriage to your starting point | Measure twice, cut once! |

| Align the dial and turn slowly | Have patience for better results |

Common Threading Dial Issues and Solutions

Identification of frequent problems encountered with threading dials. Troubleshooting tips to resolve issues quickly.Threading dials on lathes can have common issues. Many users face problems like uneven threads or incorrect measurements. These can happen due to dirt or misalignment. Here are some quick troubleshooting tips:

- Check for dirt or debris on the dial.

- Make sure the dial aligns properly with the machine.

- Look for any loose parts or damage.

By fixing these small issues, you can keep your variable speed metal lathe working well.

What are common problems with threading dials?

Common problems include uneven threading, misalignment, and dirt buildup.

Maintenance of Variable Speed Metal Lathes

Routine maintenance practices for optimal lathe function. Importance of keeping the threading dial in good condition.Keeping your metal lathe in tip-top shape is key for smooth operation. Regularly cleaning and lubricating parts will keep things running like a well-oiled machine—well, maybe not a machine from the ’80s, but pretty close! Check the threading dial often; it’s the *compass* for your projects. A working dial means accurate cuts! Here’s a quick maintenance checklist:

| Task | Frequency |

|---|---|

| Clean and lubricate | Weekly |

| Check threading dial | Before each use |

| Tighten loose screws | Monthly |

Remember, a happy lathe makes for happy threads! Don’t let just any dial ruin your day.

Safety Considerations When Using a Metal Lathe

Essential safety precautions for operating a variable speed metal lathe. Best practices to avoid accidents related to threading operations.Using a metal lathe safely is very important. Here are some key safety tips to follow:

- Always wear safety goggles and gloves.

- Keep long hair tied back and remove loose clothing.

- Check that all tools are secure before starting.

- Use the correct speed for threading operations.

- Never leave the lathe running unattended.

These essential safety precautions help to prevent accidents. Always think about your safety and the safety of others when using a variable speed metal lathe.

What should I wear while operating a metal lathe?

Always wear safety goggles and gloves. These protect your eyes and hands from any sharp pieces or metal shavings.Things to remember:

- Long hair should be tied back.

- Loose clothing can get caught in the machine.

Choosing the Right Variable Speed Metal Lathe for Threading

Key features to look for in a lathe for threading tasks. Comparison of popular variable speed lathes for threading.When choosing a variable speed metal lathe for threading, several key features matter. Look for a precision threading dial to make accurate cuts. Ensure the lathe has a strong motor for smooth operation. Easy controls lead to better results. Check for a durable construction to last through projects. Popular models include:

- Mini Lathe by Grizzly

- Central Machinery by Harbor Freight

- Jet 321360

Each offers reliability and performance for threading tasks. A helpful lathe can transform your projects!

What features are important in a lathe for threading?

Key features include precision, speed control, and durability. A solid motor gives better results and makes threading easier.

Resources and Further Reading

Recommended books and online courses on metal lathe operation. Links to forums and communities for metalworking enthusiasts.If you want to dive deeper into the world of metal lathes, many resources can help! For books, **”The Lathe Book”** is a great starter. It covers everything from basics to advanced tricks. If online courses are your thing, try **Udemy** or **Coursera**; they offer practical training. Plus, communities like the **r/metalworking subreddit** are perfect for getting tips and sharing your funny lathe mishaps. Check out the table below for more resources!

| Resource Type | Recommended Titles/Links |

|---|---|

| Books | The Lathe Book |

| Online Courses | Udemy, Coursera |

| Forums | r/metalworking, Metalworking.com |

Conclusion

In summary, a variable speed metal lathe threading dial helps you create precise threads easily. It allows you to adjust speeds for different materials. Using it correctly can improve your projects. We encourage you to explore more about lathes and practice threading techniques. With hands-on experience, you’ll enhance your skills and confidence in metalworking. Happy turning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Variable Speed Metal Lathe Threading Dials:A variable speed metal lathe helps us make things out of metal. It spins the metal while cutting it. The threading dial helps us make grooves or threads on the metal. This is useful for making screws or bolts. You can set how fast the lathe spins to make it safer and easier to use.

Sure! Please go ahead and ask your question, and I’ll be happy to help you.

How Does The Threading Dial Work On A Variable Speed Metal Lathe, And What Is Its Purpose During The Threading Process?The threading dial helps you make threads on a metal lathe. It shows you when to move the tool for cutting. When you turn the dial, it helps line up the cuts perfectly. This way, you get nice, even threads every time. It’s important for making your work look good and fit well.

What Adjustments Or Settings Should Be Considered When Using The Threading Dial On A Variable Speed Metal Lathe For Different Thread Pitches?When you use the threading dial on a metal lathe for different thread pitches, you need to adjust a few things. First, set the gear ratio for the right pitch you want. Then, make sure the lathe speed is low enough for safe cutting. You should also move the carriage carefully so the cut is smooth. Finally, check the threading dial to know when to start and stop cutting.

Can You Explain The Differences Between Using A Threading Dial And A Tailstock For Cutting Threads On A Variable Speed Metal Lathe?When you cut threads on a metal lathe, you can use two tools: a threading dial and a tailstock. The threading dial helps you measure how far to move your cutting tool. You use it to line up the tool with the workpiece. The tailstock, on the other hand, supports the other end of the material you are cutting. It keeps everything steady while you work.

What Common Issues Might Arise When Using A Threading Dial On A Variable Speed Metal Lathe, And How Can They Be Addressed?When using a threading dial on a variable speed metal lathe, you might have a few problems. The dial could get stuck or not line up right. You can fix this by checking if it’s clean and free from dust. Sometimes, the lathe might run too fast or too slow, making it hard to thread. You can adjust the speed and practice a bit to get it just right.

How Can The Variable Speed Feature Of A Lathe Enhance The Threading Capabilities When Using The Threading Dial?The variable speed feature on a lathe lets you change how fast the machine turns. This helps you adjust the speed for threading better. When you use the threading dial, you can match the speed to your cutting needs. This makes your threading cleaner and more accurate. You get a nicer finish on your work!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Variable Speed Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A variable speed metal lathe helps us make things out of metal. It spins the metal while cutting it. The threading dial helps us make grooves or threads on the metal. This is useful for making screws or bolts. You can set how fast the lathe spins to make it safer and easier to use.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll be happy to help you.”}},{“@type”: “Question”,”name”: “How Does The Threading Dial Work On A Variable Speed Metal Lathe, And What Is Its Purpose During The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you make threads on a metal lathe. It shows you when to move the tool for cutting. When you turn the dial, it helps line up the cuts perfectly. This way, you get nice, even threads every time. It’s important for making your work look good and fit well.”}},{“@type”: “Question”,”name”: “What Adjustments Or Settings Should Be Considered When Using The Threading Dial On A Variable Speed Metal Lathe For Different Thread Pitches?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use the threading dial on a metal lathe for different thread pitches, you need to adjust a few things. First, set the gear ratio for the right pitch you want. Then, make sure the lathe speed is low enough for safe cutting. You should also move the carriage carefully so the cut is smooth. Finally, check the threading dial to know when to start and stop cutting.”}},{“@type”: “Question”,”name”: “Can You Explain The Differences Between Using A Threading Dial And A Tailstock For Cutting Threads On A Variable Speed Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you cut threads on a metal lathe, you can use two tools: a threading dial and a tailstock. The threading dial helps you measure how far to move your cutting tool. You use it to line up the tool with the workpiece. The tailstock, on the other hand, supports the other end of the material you are cutting. It keeps everything steady while you work.”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise When Using A Threading Dial On A Variable Speed Metal Lathe, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a threading dial on a variable speed metal lathe, you might have a few problems. The dial could get stuck or not line up right. You can fix this by checking if it’s clean and free from dust. Sometimes, the lathe might run too fast or too slow, making it hard to thread. You can adjust the speed and practice a bit to get it just right.”}},{“@type”: “Question”,”name”: “How Can The Variable Speed Feature Of A Lathe Enhance The Threading Capabilities When Using The Threading Dial?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The variable speed feature on a lathe lets you change how fast the machine turns. This helps you adjust the speed for threading better. When you use the threading dial, you can match the speed to your cutting needs. This makes your threading cleaner and more accurate. You get a nicer finish on your work!”}}]}