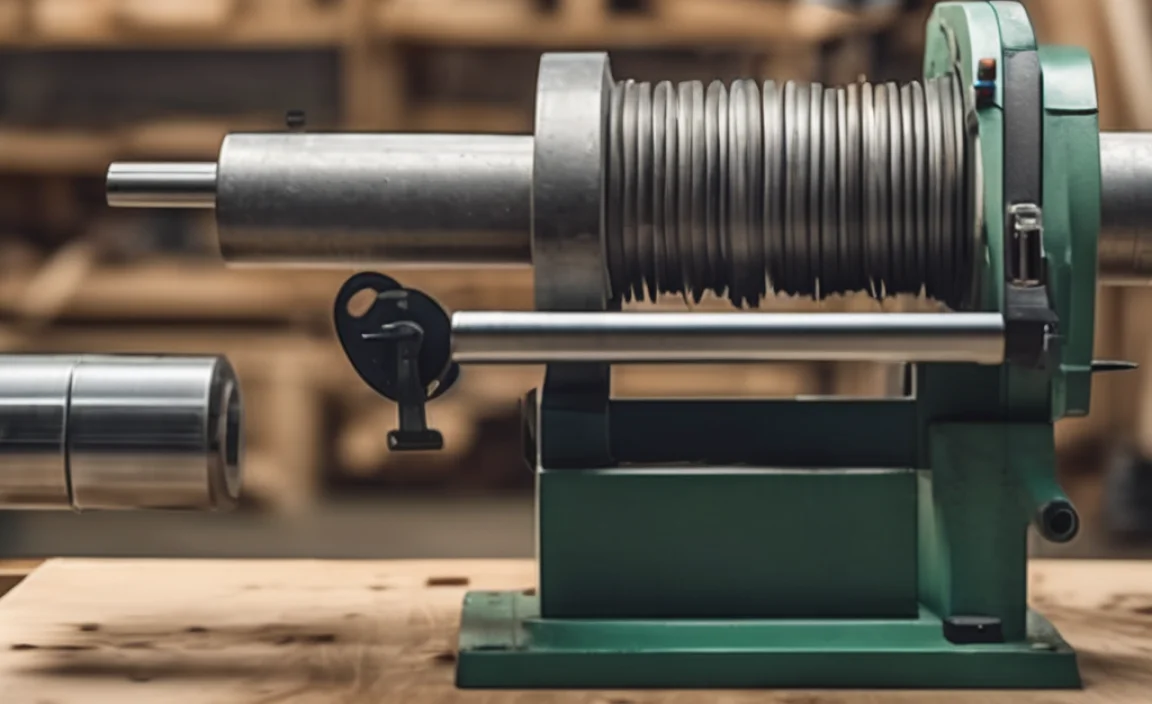

Do you love working with wood? Have you ever used a wood lathe? A wood lathe helps shape wood into beautiful objects. But sometimes, it makes strange noises. This can be annoying and even scary. Wouldn’t it be great to learn about wood lathe belt noise reduction? Let’s explore this and find ways to enjoy a quieter woodturning experience.

Key Takeaways

- Quiet belts improve your woodturning experience.

- Regular maintenance reduces noise in wood lathes.

- Proper belt tension is key for less noise.

- Using quality belts aids in wood lathe belt noise reduction.

- Lubrication helps moving parts operate smoothly.

Understanding Wood Lathe Belt Noise

Wood lathes are amazing machines that help create beautiful wood objects. But sometimes, they can be noisy. The belt on the lathe often causes this noise. When belts wear out, they may slip or squeal. This can be annoying and may even damage your machine. Knowing about wood lathe belt noise reduction helps you fix these problems. Let’s explore how to keep your wood lathe quiet and efficient.

- Belts can wear and become loose.

- Noisy belts may slip or squeal.

- Problems with belts can damage the lathe.

- Fixing belts helps reduce noise and damage.

- Maintaining belts is essential for quiet operation.

Reducing noise in your wood lathe belts is important for your work. You want your lathe to run smoothly. This helps you focus on creating beautiful things. Check your belts often for wear and tear. Keep them tight and clean. This makes your woodturning experience better and more enjoyable.

Fun Fact or Stats : The first wood lathes were used in Ancient Egypt around 1300 BC!

What Causes Wood Lathe Belt Noise?

Have you ever wondered why your wood lathe makes noise? Many things can cause this. One big reason is the condition of the belt. If it’s old, it may slip or become too loose. This creates noise. Another cause is improper tension. If the belt is too tight or too loose, it causes problems. Finally, dirt or debris can get stuck in the belt, causing noise too. Keeping an eye on these factors helps keep your lathe quiet.

How to Identify Noisy Belts?

Can you hear a squeak or a squeal? That’s a sign of a noisy belt. When you hear these sounds, check your belt. Is it loose or worn out? A good way to check is by looking at the belt’s color and texture. A healthy belt should be smooth and even. If the belt looks frayed or cracked, it’s time to replace it. Identifying noisy belts early helps prevent further damage.

How Does Belt Tension Affect Noise?

Have you ever stretched a rubber band too tight? It might have snapped! Similarly, if a belt is too tight, it may create noise. It can even damage your lathe. If it’s too loose, it slips and squeals. That’s why proper tension is important. Adjusting the belt to the correct tension helps reduce noise. It also makes your lathe last longer.

Maintaining Belt Tension

Maintaining the right belt tension is crucial for wood lathe belt noise reduction. When belts are too loose, they slip and produce noise. Too tight, and they cause unnecessary wear. To find the right tension, follow your lathe’s manual. It will guide you on how to adjust the belt properly. A good rule is to allow about a quarter-inch of play when you press the belt in the middle. Proper tension ensures your lathe runs smoothly and quietly.

- Check your manual for tension guidelines.

- Allow a quarter-inch of play.

- Adjust tension regularly.

- Don’t overtighten the belt.

- Proper tension improves machine performance.

Adjusting belt tension regularly is a part of good maintenance. It ensures your lathe operates at its best. When you hear a noise, check the tension first. This simple step can save you time and money by preventing bigger problems.

Fun Fact or Stats : Leonardo da Vinci sketched a lathe design in his notebooks!

How to Adjust Belt Tension?

Do you know how to adjust belt tension on a wood lathe? It’s easier than you think. First, turn off the lathe and unplug it. Safety first! Next, find the motor mount. Loosen the screws and push or pull the motor to adjust the belt tension. Check the manual for specific steps. Make sure the belt has a little give, but not too much. Tighten the screws, and you’re done!

Why Is Proper Tension Important?

Proper belt tension is key for noise reduction. If a belt is too tight, it can wear out faster. If it’s too loose, it slips. Both can cause noise and damage your lathe. Keeping the belt at the right tension extends the belt’s life. It also makes your machine quieter. Regularly checking and adjusting tension is a simple but important task.

What Happens If You Ignore Belt Tension?

What if you don’t keep an eye on belt tension? Ignoring it can lead to many problems. Your lathe will become noisy and may not work well. The belt could wear out quickly, needing frequent replacements. It might even break, causing damage to the lathe. Proper maintenance helps avoid these issues. Regular checks keep your lathe running smoothly and quietly.

Choosing the Right Belt Material

Choosing the right belt material is crucial for wood lathe belt noise reduction. Different materials have different strengths. Rubber belts are common and provide good grip. They also absorb some noise. However, they can wear out faster. Polyurethane belts last longer and run quietly. Kevlar belts are strong and durable. Each material has its pros and cons. Think about what you need most, like durability or quiet operation.

- Rubber belts provide good grip.

- Polyurethane belts last longer.

- Kevlar belts are very strong.

- Each material has pros and cons.

- Choose based on your needs.

When picking a belt, consider what’s most important for you. Do you want something that lasts a long time? Or maybe you prefer a quieter operation? Each belt type offers something different. Understanding these options helps you make the best choice for your lathe.

Fun Fact or Stats : The world’s largest lathe is housed in the USA and can turn objects over 100 feet long!

What Are the Pros and Cons of Rubber Belts?

Rubber belts are popular in wood lathes. Why? They offer a good grip and are affordable. But, they have some downsides too. They wear out faster than other types. When they wear out, they can slip, causing noise. Despite this, they are a great choice for beginners. They are easy to replace and can handle basic projects well.

Why Consider Polyurethane Belts?

Polyurethane belts are known for their durability. They last longer than rubber belts. They are also quieter. This makes them a good choice for reducing noise. They don’t slip easily, even with heavy use. However, they can be more expensive. For someone who uses a lathe often, they might be worth the cost. They provide a quieter, more efficient experience.

Is Kevlar the Best Choice for Strength?

Kevlar belts are incredibly strong. They can handle tough jobs without breaking. They are also durable, which means they last a long time. They are great for heavy-duty projects. But, they can be expensive. They might be more than what a beginner needs. If you have tough projects, Kevlar belts are a top choice. They offer strength and durability for serious work.

| Material | Durability | Quietness | Cost |

|---|---|---|---|

| Rubber | Moderate | Moderate | Low |

| Polyurethane | High | High | Moderate |

| Kevlar | Very High | High | High |

Regular Maintenance for Noise Reduction

Regular maintenance is key to wood lathe belt noise reduction. Without it, belts may wear out quickly. This leads to slipping and noise. Regular checks keep your lathe running smoothly. Clean parts often to remove debris. Replace worn-out belts before they become a problem. Lubricate moving parts to reduce friction and noise. These simple tasks can make a big difference.

- Check belts for wear and tear.

- Replace worn-out belts promptly.

- Keep the lathe clean.

- Lubricate moving parts regularly.

- Regular maintenance prevents bigger problems.

Maintaining your lathe is not hard. It just requires regular attention. Spend a little time each month checking it over. This small effort can prevent noise issues and extend the life of your machine. It also ensures your projects go smoothly without interruptions.

Fun Fact or Stats : A well-maintained lathe can last for decades and is often passed down as a family heirloom!

How Often Should You Check Your Lathe?

How often do you check your wood lathe? It’s a good idea to inspect it once a month. Look for any signs of wear and tear. Pay special attention to the belts. If they look worn, replace them. Regular checks help catch potential problems early. This prevents noise and keeps your lathe running smoothly. It’s a simple way to protect your investment.

What Parts Need Regular Lubrication?

Lubrication is important for reducing noise. But which parts need it? Focus on the moving parts. This includes the spindle, bearings, and gears. A little oil goes a long way. It reduces friction, which reduces noise. Be sure to use the correct type of oil as per your lathe’s manual. Regular lubrication keeps your machine running smoothly and quietly.

Why Cleanliness Matters for Noise Reduction?

Does a clean lathe really run quieter? Yes, it does! Dirt and debris can cause belts to slip. This creates noise. Cleaning your lathe regularly prevents this. Wipe down surfaces and remove any built-up debris. This simple task keeps noise levels down and helps your lathe last longer. A clean lathe is a happy, quiet lathe!

Using High-Quality Belts

High-quality belts play a big role in wood lathe belt noise reduction. They last longer and work more efficiently. Cheap belts wear out quickly and may slip, causing noise. Investing in good-quality belts might cost more initially. But, they save money in the long run. They reduce the need for frequent replacements. This makes your woodturning experience smoother and more enjoyable.

- High-quality belts last longer.

- They reduce the need for replacements.

- Good belts work efficiently.

- They help prevent belt slippage.

- Investing in quality saves money over time.

Using high-quality belts is smart. They ensure your lathe runs smoothly and quietly. Look for belts recommended by your lathe’s manufacturer. This ensures a perfect fit and performance. A good belt makes a difference in your woodturning projects.

Fun Fact or Stats : The longest continuous wood lathe belt is over 30 feet long!

What Makes a Belt High-Quality?

What should you look for in a high-quality belt? First, check the material. It should be durable and strong. Next, consider the brand. Reputable brands often offer better quality. Finally, read reviews. Other users can give insights into performance. A high-quality belt reduces noise and lasts longer. It’s a worthwhile investment for any woodworker.

Where to Buy Quality Belts?

Buying a quality belt is important. But where can you find them? Start with your lathe’s manufacturer. They often sell parts that fit perfectly. Online stores also offer a variety of options. Be sure to read reviews before buying. This helps ensure you’re getting a good product. Investing in a quality belt makes a big difference in your lathe’s performance.

Why Do Cheap Belts Cause Noise?

Why might a cheap belt cause noise? They often wear out quickly. This leads to slipping and squealing. Cheap belts might not fit well, causing improper tension. All of these issues create noise. Investing in a quality belt helps avoid these problems. It ensures a better fit, longer life, and a quieter operation.

Conclusion

Wood lathe belt noise reduction is important for a pleasant woodworking experience. Maintaining your lathe, choosing the right belt, and ensuring proper tension all help. Regular checks and using high-quality belts make a difference. With these tips, you can enjoy woodturning with less noise and more fun.

FAQs

Question: How often should I check my wood lathe belts?

Answer: Check your wood lathe belts at least once a month. Look for signs of wear or damage. Regular checks help catch problems early, ensuring your lathe runs smoothly and quietly. Promptly replacing worn belts aids in wood lathe belt noise reduction.

Question: What is the best material for reducing noise?

Answer: Polyurethane belts are great for reducing noise. They are durable and provide a quiet operation. Kevlar belts also offer strength and quietness, but they can be more expensive. Choose based on your needs and budget for effective noise reduction.

Question: Why does my wood lathe make a squeaking sound?

Answer: A squeaking sound often means your belt is slipping. It might be too loose or worn out. Check the belt for wear and adjust the tension. Replacing worn belts can help reduce noise and improve performance.

Question: How can I maintain proper belt tension?

Answer: To maintain proper belt tension, follow your lathe’s manual for guidance. Ensure there is a quarter-inch of play when pressed. Regularly check the tension and adjust as needed. Proper tension reduces noise and prolongs belt life.

Question: Can a dirty lathe cause noise?

Answer: Yes, dirt and debris can cause belts to slip, creating noise. Regularly clean your lathe to remove dirt. This helps prevent noise and keeps your machine in good condition. A clean lathe runs more quietly.

Question: Are high-quality belts worth the cost?

Answer: Yes, high-quality belts are worth the investment. They last longer and reduce noise. While they may be costlier initially, they save money over time by reducing the need for frequent replacements. They enhance your woodturning experience.