Have you ever wondered how woodworkers keep their tools sharp? They often use a special tool called a carbide insert. Keeping it sharp is crucial for smooth and precise woodturning. But have you heard about the art of wood lathe carbide insert sharpening? It’s a fascinating process that helps woodworkers create beautiful pieces. Let’s explore this exciting topic and learn why it’s important.

Key Takeaways

- Sharp tools are crucial for safe woodturning.

- Carbide inserts are easy to maintain.

- Learn proper wood lathe carbide insert sharpening techniques.

- Carbide inserts can be replaced or rotated.

- Proper sharpening increases tool lifespan.

What is Wood Lathe Carbide Insert Sharpening?

Wood lathe carbide insert sharpening is the process of keeping your carbide tools ready for action. Carbide inserts are small, hard pieces used in woodworking tools. They help you create smooth surfaces on wood. When they get dull, work becomes hard and messy. Sharpening these inserts is not just about making them sharp. It’s about ensuring your woodworking projects turn out great.

- Carbide inserts save time and effort.

- They fit into different wood lathe tools.

- Sharpening keeps them effective.

- Improves the quality of woodwork.

- Increases tool lifespan.

- Reduces the need for replacement.

To sharpen carbide inserts effectively, you need the right tools. A diamond stone or wheel can help. Sharpening carbide inserts needs patience and practice. But once you get it right, your wood lathe projects will shine. Think of it like giving your tools a new life. Keeping them in top shape means less hassle and better results.

Fun Fact: Did you know carbide is one of the hardest materials on Earth?

Why Use Carbide Inserts?

Carbide inserts are popular among woodworkers for several reasons. First, they last much longer than regular steel tools. This makes them a great investment. Have you ever wondered why professional woodworkers prefer them? It’s because carbide stays sharp longer and cuts smoother. They are also easy to replace. When one edge is dull, just rotate it for a fresh one.

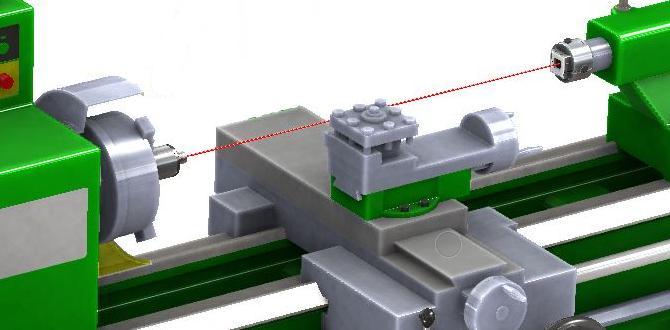

How Does a Wood Lathe Work?

A wood lathe spins pieces of wood at high speeds. It’s like magic! You can shape wood into beautiful objects. With carbide inserts, it’s even more efficient. Have you ever seen a bowl made on a lathe? The smooth surface is thanks to sharp tools. Carbide inserts make the job easier and more precise.

What Makes Carbide So Special?

Carbide is a super hard material. It’s made from carbon and tungsten. This combination makes carbide tools last longer. They can cut through tough wood without dulling quickly. Imagine cutting through a hard piece of wood with ease. That’s the power of carbide! With proper sharpening, these tools stay effective for a long time.

Tools Needed for Sharpening Carbide Inserts

To sharpen carbide inserts, you’ll need a few tools. First, a diamond stone or wheel is essential. This will grind the carbide to a sharp edge. You might wonder why not use a regular stone? Regular stones aren’t tough enough for carbide. Next, a honing guide helps maintain the right angle. Safety gear like goggles and gloves protect you while you work.

- Diamond stone or wheel for sharpening.

- Honing guide for angle precision.

- Safety goggles and gloves.

- Clean cloth to wipe inserts.

- Lubricant to reduce friction.

Sharpening carbide inserts requires care. Start by securing the insert in the honing guide. Use the diamond stone to evenly sharpen the edge. Apply consistent pressure and check your progress. Wipe the insert clean, and it’s ready for use. With practice, you’ll get faster and more precise. Sharpening is an art worth mastering.

Fun Fact: Did you know diamonds are the hardest materials known to man?

Choosing the Right Diamond Stone

Picking the right diamond stone is crucial. Consider the grit size. Finer grit means a smoother finish. Coarse grit removes more material quickly. Have you ever wondered which grit is best? If you need quick sharpening, start with coarse grit. Then, switch to finer for a polished edge. Finding the right balance is key to effective sharpening.

Using a Honing Guide

A honing guide helps keep your sharpening angle steady. Imagine trying to keep your hand perfectly still. It’s hard! The honing guide holds the insert for you. This ensures a consistent edge. Why is this important? Consistency means better performance when turning wood. With a honing guide, sharpening becomes easier and more accurate.

Importance of Safety Gear

Safety gear is crucial when sharpening carbide inserts. Why risk an injury? Wearing goggles protects your eyes from flying debris. Gloves give a firm grip and protect your hands. It’s always better to be safe than sorry. Have you ever seen sparks fly off a grinding stone? Safety gear keeps you protected, so you can focus on better sharpening.

Benefits of Regular Sharpening

Regular sharpening of carbide inserts offers many benefits. The most obvious one is improved performance. Sharp tools cut cleaner and faster. This means you can complete projects quicker. Have you ever worked with a dull tool? It’s frustrating and tiring. Regular sharpening maintains efficiency and reduces effort.

- Improved cutting performance.

- Longer tool life.

- More precise woodturning results.

- Less effort required in projects.

- Enhanced safety during use.

- Reduced chance of tool damage.

Keeping carbide inserts sharp also prolongs their lifespan. When inserts are dull, more force is needed. This can damage both the tool and the wood. Regular sharpening avoids these issues. It ensures your tools are always ready. With carbide inserts, regular maintenance is key to achieving the best results.

Fun Fact: Regularly sharpened tools can last twice as long!

Cutting Performance

Sharp carbide tools offer superior cutting performance. They glide through wood like a hot knife through butter. Have you ever noticed how easy it is to slice through a cake? The same principle applies here. With a sharp tool, cuts are smooth and precise. No more rough edges or uneven surfaces. Regular sharpening ensures top-notch performance.

Prolonging Tool Life

Proper maintenance extends the life of your carbide tools. Why replace when you can maintain? Regular sharpening reduces wear and tear. This means fewer replacements and more savings. Imagine if you could double the life of your tools. That’s possible with regular care and sharpening. It’s a smart investment for any woodworker.

Better Safety

Safety is a key reason to keep tools sharp. Dull tools require more force. This can lead to slips and injuries. Have you ever used a blunt knife? It’s risky! Sharp tools are safer. They cut effortlessly and reduce accidents. Regular sharpening ensures you’re working safely and efficiently. It’s peace of mind for every woodworking project.

Common Mistakes in Sharpening

Sharpening carbide inserts is an art. However, errors can occur. One mistake is using the wrong sharpening tool. Carbide needs a diamond stone. Regular stones won’t work. Another error is applying too much pressure. This can damage the insert. Have you ever pushed too hard on something and it broke? It’s the same with sharpening. Patience is key.

- Using incorrect sharpening tools.

- Applying excessive pressure.

- Ignoring the correct angle.

- Not cleaning the insert afterward.

- Skipping safety measures.

Ignoring the proper angle is another common mistake. The right angle ensures effective sharpening. Not cleaning the insert after sharpening can leave debris. This affects performance. Always remember safety measures. Wear goggles and gloves. These mistakes can lead to poor results and damage. Avoid them for the best wood lathe experience.

Fun Fact: Patience and precision are the keys to perfect sharpening!

Choosing the Right Tools

Choosing the right sharpening tools is crucial. Not all sharpeners are equal. Have you ever tried fitting a square peg into a round hole? It’s impossible! The same goes for sharpening tools. For carbide inserts, use diamond stones. They are tough enough to handle carbide. Using the right tool ensures effective sharpening and better results.

Maintaining Proper Angle

Maintaining the proper angle is important in sharpening. Why does this matter? The angle affects how well the tool cuts. Imagine trying to write with a dull pencil. It doesn’t work well. The right angle ensures a sharp edge. Consistent sharpening angles lead to consistent results. It’s an art that takes practice and precision.

Cleaning After Sharpening

Cleaning your inserts after sharpening is important. Leaving debris can affect performance. Have you ever tried to paint with a dirty brush? The results aren’t good. Clean inserts mean better cuts and smoother surfaces. Use a clean cloth to wipe them down. This simple step ensures your tools remain effective and ready for the next project.

Carbide Insert vs. Steel Tools

Carbide inserts and steel tools both have their benefits. But how do they compare? Carbide is tougher and lasts longer. Steel tools are cheaper and easier to sharpen. Have you ever bought something that lasts longer but costs more? That’s carbide. It’s an investment that pays off over time.

| Feature | Carbide Insert | Steel Tool |

|---|---|---|

| Durability | Very High | Medium |

| Cost | Higher | Lower |

| Ease of Sharpening | Moderate | Easy |

| Performance | Consistent | Varies |

- Carbide is more durable than steel.

- Steel tools are cheaper initially.

- Carbide offers consistent performance.

- Steel is easier to sharpen.

- Carbide handles tough materials well.

Carbide inserts excel in cutting performance. They handle tough materials effortlessly. However, they cost more initially. Steel tools are affordable but need frequent sharpening. Which one is better? It depends on your project needs. Both have their place in a woodworker’s toolkit. Understanding their differences helps you make an informed choice.

Fun Fact: Carbide tools can hold an edge ten times longer than steel!

Durability Comparison

Carbide inserts last longer than steel. They resist wear and tear better. Have you ever tried breaking a diamond? It’s nearly impossible! That’s carbide for you. Steel is softer and wears out faster. For long-term use, carbide is the winner. It’s an investment that saves money over time. For tough projects, choose carbide.

Cost Considerations

Cost is a key factor in choosing tools. Carbide is more expensive. But why pay more? It lasts longer and performs better. Steel is cheaper but needs frequent replacement. Have you ever bought a cheap toy that broke quickly? Sometimes, paying more upfront saves money later. Weigh the costs and benefits for your projects.

Performance and Efficiency

Carbide tools offer consistent performance. They stay sharp longer. Imagine cutting paper with a dull pair of scissors. It’s frustrating! Carbide tools cut smoothly and efficiently. Steel tools perform well but dull quickly. Consider the time and effort saved with carbide. It’s a smart choice for serious woodworkers.

Conclusion

Wood lathe carbide insert sharpening is vital for great woodworking. It keeps your tools in top shape. Sharp carbide inserts mean better cuts and less effort. They make your projects shine. Learn the art of sharpening for better results. With practice and patience, you can master it. Keep those inserts sharp and enjoy the craft!

FAQs

Question: What are carbide inserts?

Answer: Carbide inserts are small, hard tips used in woodworking tools. They help cut wood smoothly. Made from tungsten and carbon, they are durable and long-lasting. They can be rotated and replaced as needed, ensuring continuous sharpness and effectiveness.

Question: Why is sharpening important?

Answer: Sharpening is important to maintain tool efficiency. Dull tools make work hard and unsafe. Regular sharpening ensures clean cuts and reduces effort. It also extends the life of tools, saving money in the long run.

Question: How do I sharpen carbide inserts?

Answer: To sharpen carbide inserts, use a diamond stone or wheel. Secure the insert in a honing guide. Maintain the correct angle while sharpening. Apply consistent pressure and check your progress frequently. Always clean the insert after sharpening for best results.

Question: What tools do I need for sharpening?

Answer: For sharpening, you will need a diamond stone or wheel. A honing guide helps maintain the right angle. Safety gear like goggles and gloves are also important. These tools ensure effective and safe sharpening of carbide inserts.

Question: Are carbide inserts better than steel tools?

Answer: Carbide inserts are more durable and last longer than steel tools. They offer consistent performance and handle tough materials well. Steel tools are cheaper and easier to sharpen but dull quickly. The choice depends on your woodworking needs and budget.

Question: Can sharpening improve tool lifespan?

Answer: Yes, regular sharpening improves tool lifespan. It keeps the edges sharp and reduces wear. This means less force is needed when cutting, preventing damage. Sharpening is a simple way to extend the life of your carbide inserts.