Have you ever watched a wood lathe in action? It’s fascinating how these machines can turn a simple piece of wood into a beautiful object. But did you know that getting the center alignment just right is key to making perfect shapes? If the center is off, your project can turn into a disaster quickly.

Many woodworkers struggle with center alignment techniques. They often wonder, what’s the best way to ensure everything spins smoothly? Imagine starting a project only to realize the wood is wobbling. That would be frustrating, right?

For anyone who loves woodworking, mastering center alignment is a game-changer. In this article, you will learn simple techniques to align your wood lathe properly. With the right steps, you can create stunning pieces without the hassle of mistakes.

Wood Lathe Center Alignment Techniques: Ensuring Precision

Wood Lathe Center Alignment Techniques

Achieving proper alignment on a wood lathe is essential for smooth, accurate turning. Discover simple methods like using a caliper or a dial indicator to check for accuracy. Ever thought about how a tiny misalignment can ruin your project? Aligning the centers not only ensures better results but also enhances safety. Understanding these techniques can save time and materials, leading to more satisfying woodturning experiences. Try these tips and watch your skills improve!Understanding Wood Lathe Alignment

Explanation of what wood lathe alignment is. Importance of proper alignment for quality woodworking.Imagine trying to spin a basketball on your finger. If your finger isn’t under the center, the ball wobbles and spins poorly. That’s similar to wood lathe alignment! Proper alignment means the workpiece is correctly centered. This ensures your cuts are smooth and beautiful. Without it, you risk uneven surfaces and splintered wood. You don’t want your masterpiece looking like a lopsided pancake, right?

| Alignment Benefits | Consequences of Poor Alignment |

|---|---|

| Quality cuts | Wonky surfaces |

| Less waste | Dangerous splinters |

| Faster work | Frustration! |

In woodworking, keeping things straight really matters. So, remember: align, spin, and let the magic happen!

Common Misalignment Issues

Identifying symptoms of misalignment. Impact of misalignment on projects and tool wear.Sometimes, you might notice your wood lathe is behaving a bit strangely. Common symptoms of misalignment include uneven cuts or vibrations that feel like your lathe had too much coffee. This misalignment can mess up your project and even cause tools to wear out faster than usual. Proper alignment is key; a crooked setup can lead to frustrating errors, affecting your wood’s beauty and your mood. Remember, a happy lathe makes for a happy woodworker!

| Symptoms of Misalignment | Impact on Projects | Impact on Tool Wear |

|---|---|---|

| Uneven cuts | Poor finish quality | Faster dulling |

| Vibrations | Wasted materials | Increased wear |

| Strange noises | Frustration in craftsmanship | Shorter lifespan |

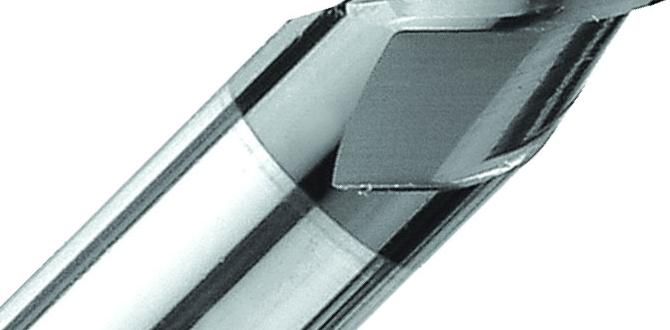

Measuring Center Alignment

Tools needed for accurate measurement. Stepbystep process to measure alignment.To measure center alignment accurately, you’ll need a few trusty tools. Grab a ruler, caliper, and a sharpie. Once you have them, follow these easy steps. First, find the tailstock and the headstock. Measure the distance between them. Next, use the caliper to check the spindle. Mark the center with your sharpie. Align them to make sure they match up. It’s like matching socks, but way cooler! Remember, good alignment helps prevent wobbly results!

| Tool | Purpose |

|---|---|

| Ruler | Measure distance |

| Caliper | Check spindle |

| Sharpie | Mark center |

Techniques for Proper Center Alignment

Detailed description of the “Check and Adjust” method. Stepbystep guide for using alignment tools.One great way to align your wood lathe is the “Check and Adjust” method. Start by using alignment tools like a dial indicator or a laser guide. Here’s a simple step-by-step guide:

- First, set the lathe to turn off.

- Use the dial indicator near the center. Check for any wobble.

- If there is movement, adjust the headstock. Tighten or loosen it until it’s still.

- Finally, recheck the alignment. Keep adjusting until it’s perfect!

Remember, even slight shifts can cause issues, so take your time!

How can I align my wood lathe’s center?

Use the “Check and Adjust” method with tools like a dial indicator. This helps fix any wobbles and ensures a smooth turning experience.

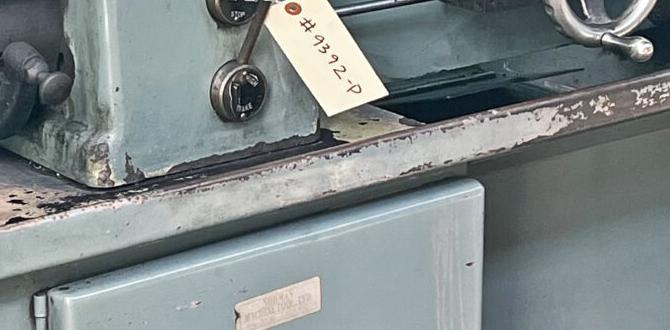

Using a Tailstock for Alignment

Role of the tailstock in achieving alignment. Adjustments that can be made using the tailstock.The tailstock plays an important role in keeping your woodworking project aligned. It helps support the workpiece while the lathe spins. This support is key for even cuts and smooth shapes. You can also make adjustments using the tailstock. This helps to ensure proper alignment. Here’s how it can help:

- Provides extra stability during cutting.

- Allows for fine-tuning of alignment.

- Prevents vibrations that could ruin the cut.

Why is the tailstock important for alignment?

The tailstock stabilizes the workpiece, making accurate cuts possible. Without it, pieces can wobble and create messy work.

Using a Laser Alignment Tool

Advantages of using laser tools. How to set up and use a laser tool for precise alignment.Using a laser alignment tool is like having a magic wand for perfect wood lathe setup. It offers super accuracy and saves time. Setting it up is easy. Just place the tool on the lathe, turn it on, and watch the light beam dance! Aim the beam at the center of your workpiece while adjusting the lathe. It’s like playing laser tag, but with wood! Check out the table below for a quick setup guide:

| Step | Description |

|---|---|

| 1 | Place laser tool on the lathe |

| 2 | Turn on the laser |

| 3 | Align beam to workpiece center |

| 4 | Adjust lathe until aligned |

With this trick, you’ll conquer any project and impress your friends without breaking a sweat! Remember, precision is key, and a little laser helps a lot!

Common Mistakes to Avoid

List of frequent errors during alignment. Tips for troubleshooting misalignment issues.While aligning the wood lathe, mistakes can happen. Here are some common errors to watch out for:

- Not checking the tailstock and headstock alignment.

- Ignoring the level of the lathe bed.

- Forgetting to tighten adjusting screws fully.

If you notice problems, try these tips:

- Recheck using a level tool.

- Adjust slowly and test frequently.

- Ask for help or look up videos for guidance.

A little care helps avoid big mistakes!

What are the common problems with wood lathe alignment?

Common problems include misalignment between the headstock and tailstock, which can cause uneven cuts. Make sure both parts line up correctly to ensure smooth operation.

What should I do if my wood lathe is misaligned?

If your wood lathe is misaligned, recheck its level and tighten any loose components. This can help bring everything back to the right position quickly.

Maintaining Alignment Over Time

Best practices for regular maintenance. How to check alignment periodically.Keeping your wood lathe aligned takes some work, but it’s worth it. Regular maintenance helps prevent issues. To maintain good alignment, follow these best practices:

- Check alignment weekly for the first month after setup.

- Use a caliper or a ruler to confirm everything is straight.

- Clean dust and debris regularly.

- Tighten any loose parts as needed.

Checking alignment is easy. Periodically, look for signs of wear or misalignment. Make small adjustments when you notice problems. This prevents bigger issues later.

How often should I check my wood lathe alignment?

Check it at least once a month for the best results. More checks are needed if you use your lathe daily.

Case Studies: Real-World Examples

Examples of projects affected by alignment issues. Success stories of improved alignment techniques.Alignment issues can really mess up wood projects. One crafter tried to make a beautiful bowl. However, the wood was not aligned right, causing it to wobble. This led to a lot of wasted time and material. Yet, in another case, a woodworker improved alignment techniques. They used a new guide method, and the results were amazing! They created a perfect, smooth table. The right alignment made all the difference.

What are some examples of projects affected by alignment issues?

Common examples include:

- Wobbly chairs

- Uneven bowls

- Scratched tables

What are success stories of improved alignment techniques?

Success stories feature:

- Perfectly round bowls

- Beautiful furniture with smooth finishes

- Accurate cutting of wood pieces

Conclusion

In summary, wood lathe center alignment techniques are vital for good results. You can use tools like a dial gauge or a simple ruler. Double-check your setup before you start turning. This helps prevent mistakes and ensures your projects look great. Explore more resources to learn the best methods for your woodworking adventures! Happy crafting!FAQs

What Are The Common Methods For Achieving Proper Alignment Of The Tailstock And Headstock On A Wood Lathe?To align the tailstock and headstock of a wood lathe, you can use a few simple methods. First, you can check if they are straight by measuring the distance between them. If they are not lined up, adjust the tailstock until it matches the headstock. Another way is to use a long, straight piece of wood to see if it spins evenly. If it wobbles, you need to adjust the tailstock again. Always double-check your measurements to make sure they are correct!

How Can You Determine If The Spindle Axis Of Your Lathe Is Properly Aligned With The Workpiece?To check if the spindle axis of your lathe is aligned, start by placing a ruler or tool beside your workpiece. Look for gaps between the ruler and the workpiece. If the ruler touches both sides evenly, then you are good to go! If there’s a gap on one side, the spindle might not be aligned. Adjust it and try again until it fits perfectly.

What Tools Or Devices Can Be Utilized To Check And Adjust The Alignment Of A Wood Lathe?You can use a few simple tools to check and adjust a wood lathe’s alignment. A level helps you see if the lathe is straight. You can also use a ruler or caliper to measure distances. A dial indicator shows you how much the parts move. These tools help make sure everything spins smoothly.

How Does Misalignment Affect The Turning Process And The Quality Of The Finished Wood Piece?Misalignment means things aren’t lined up right when we work on the wood. This can make the turning process bumpy and uneven. When we turn the wood, it might wobble or shake, which can create mistakes. As a result, the finished piece may look rough or not as nice. To make good furniture, we need everything to be lined up perfectly!

What Are Some Best Practices For Maintaining And Regularly Checking The Alignment Of A Wood Lathe?To keep your wood lathe working well, check its alignment often. First, make sure the tailstock and headstock are lined up straight. You can do this by measuring from the center of each. Clean the lathe regularly to avoid dust build-up. Lastly, always follow the manufacturer’s guidelines for maintenance. This helps your lathe last longer and work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Methods For Achieving Proper Alignment Of The Tailstock And Headstock On A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock and headstock of a wood lathe, you can use a few simple methods. First, you can check if they are straight by measuring the distance between them. If they are not lined up, adjust the tailstock until it matches the headstock. Another way is to use a long, straight piece of wood to see if it spins evenly. If it wobbles, you need to adjust the tailstock again. Always double-check your measurements to make sure they are correct!”}},{“@type”: “Question”,”name”: “How Can You Determine If The Spindle Axis Of Your Lathe Is Properly Aligned With The Workpiece? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the spindle axis of your lathe is aligned, start by placing a ruler or tool beside your workpiece. Look for gaps between the ruler and the workpiece. If the ruler touches both sides evenly, then you are good to go! If there’s a gap on one side, the spindle might not be aligned. Adjust it and try again until it fits perfectly.”}},{“@type”: “Question”,”name”: “What Tools Or Devices Can Be Utilized To Check And Adjust The Alignment Of A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a few simple tools to check and adjust a wood lathe’s alignment. A level helps you see if the lathe is straight. You can also use a ruler or caliper to measure distances. A dial indicator shows you how much the parts move. These tools help make sure everything spins smoothly.”}},{“@type”: “Question”,”name”: “How Does Misalignment Affect The Turning Process And The Quality Of The Finished Wood Piece? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Misalignment means things aren’t lined up right when we work on the wood. This can make the turning process bumpy and uneven. When we turn the wood, it might wobble or shake, which can create mistakes. As a result, the finished piece may look rough or not as nice. To make good furniture, we need everything to be lined up perfectly!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Maintaining And Regularly Checking The Alignment Of A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your wood lathe working well, check its alignment often. First, make sure the tailstock and headstock are lined up straight. You can do this by measuring from the center of each. Clean the lathe regularly to avoid dust build-up. Lastly, always follow the manufacturer’s guidelines for maintenance. This helps your lathe last longer and work better!”}}]}