Wood Lathe Chuck Jaws for Bowl Turning: Gripping Your Creations with Precision

When it comes to transforming a rough piece of wood into a beautifully shaped bowl on your lathe, the connection between your workpiece and the machine is paramount. This crucial link is provided by the chuck, and more specifically, by its jaws. The right wood lathe chuck jaws for bowl turning can elevate your work from merely adequate to truly stunning, offering unwavering grip, unparalleled precision, and the confidence to tackle ambitious projects. Choosing the perfect set of jaws is not just a functional decision; it’s an investment in your woodworking artistry.

The world of woodturning is vast, offering a myriad of techniques and styles. However, for anyone delving into the art of creating bowls, the selection of chuck jaws becomes a foundational element of success. Unlike turning spindles or smaller projects, bowls present unique challenges. Their inherent shapes, considerable weight, and the forces exerted during the turning process demand a secure and reliable holding method. This is where specialized bowl turning jaws come into play, designed to adapt to the varying contours and increasing demands of bowl creation.

Understanding Wood Lathe Chuck Jaws for Bowl Turning: The Foundation of Your Projects

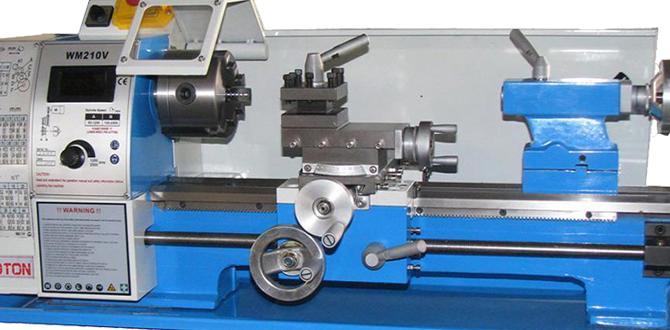

At its core, a chuck on a wood lathe serves as the mechanism to securely hold your workpiece. It typically attaches to the lathe spindle and expands or contracts to grip the wood. The jaws are the adjustable components of the chuck, responsible for making direct contact with the workpiece. For bowl turning, the primary concerns revolve around gripping the exterior (often with tenons or recesses) and potentially the interior (for hollowing).

The evolution of chuck technology has led to a diverse range of jaw styles, each designed to address specific needs. For bowl turners, common jaw types include:

Standard Jaws: These are often the default jaws that come with a chuck. They are versatile and can handle a variety of tasks, but may require specialized inserts or adapters for optimal bowl turning.

Bowl Face Jaws: These jaws are designed to grip the face of the bowl, typically by expanding into a recess or contracting onto a tenon. They are crucial for the initial stages of shaping the exterior and for re-chucking after the base has been turned.

Grips Jaws: These often feature serrated or rubberized surfaces to provide excellent friction and grip, especially when working with larger or more challenging woods.

Specialty Jaws: This category encompasses jaws designed for specific tasks, such as gripping very large diameter bowls, or jaws with extreme reach for deep bowls.

The material of the jaws also matters. Most are made from hardened steel for durability and gripping power. However, some may incorporate wood inserts or rubber padding to protect delicate surfaces or prevent marring.

Choosing the Best Wood Lathe Chuck Jaws for Bowl Turning

Selecting the best wood lathe chuck jaws for bowl turning involves considering several key factors. Your lathe’s chuck model is the primary determinant, as jaws are generally specific to particular chuck brands and sizes. Beyond compatibility, think about the types of bowls you intend to create:

Size and Weight of Workpieces: Are you turning small decorative bowls or large, heavy-duty serving bowls? Larger and heavier pieces demand jaws with greater gripping capacity and strength.

Tenon vs. Recess Grip: Most bowl turning involves creating either a tenon (a protruding peg) on the base of the bowl or a recess (a female socket) that the chuck jaws can grip. Different jaw sets are optimized for one or the other, or offer versatility between them. Some jaws are designed to expand outwards into a recess, while others contract inwards onto a tenon.

Jaw Reach and Offset: For deep bowls, you’ll need jaws with sufficient reach to grip the base without encroaching on the turning area. Jaws with an offset can provide additional clearance.

Surface Treatment: Consider if you need jaws with a smooth surface to avoid marring delicate wood, or if more aggressive teeth are acceptable for maximum grip.

Versatility: Many turners opt for a set of versatile jaws that can handle a range of bowl sizes and gripping methods, perhaps utilizing interchangeable inserts.

For beginners, a good general-purpose set of bowl jaws that can grip both tenons and recesses is an excellent starting point. As your skills and projects advance, you might invest in more specialized jaws.

Stunning Results: How the Right Jaws Contribute to Your Masterpieces

The impact of using the correct wood lathe chuck jaws for bowl turning on the perceived stunning quality of your work cannot be overstated.

Security and Confidence: A secure grip allows you to remove more material, establish crisp profiles, and achieve finer details with confidence. You can push the boundaries of your design without the nagging worry of a workpiece loosening.

Precision and Symmetry: Well-designed jaws, when properly mounted and adjusted, ensure that your workpiece runs true. This is fundamental for achieving symmetrical forms, precise rim treatments, and clean interior surfaces. Inconsistent gripping can lead to vibrations and uneven cuts, diminishing the overall finish.

Extended Creative Possibilities: With robust and versatile jaws, you can experiment with more challenging woods, larger dimensions, and intricate shapes. Imagine reliably turning a massive lidded bowl or a delicately thin-walled vessel – the right jaws make these feats achievable.

* Efficiency: A secure and easily adjustable chuck system speeds up the turning process. Less time spent worrying about jaw settings or re-chucking means more time dedicated to the creative act of turning.

Investing in quality chuck jaws is not just about holding wood; it’s about enabling your creativity to flourish. The “stunning” aspect of your turned bowls often stems from the flawless execution made possible by the reliable foundation that your chuck jaws provide. They are the unsung heroes, silently but effectively transforming your vision into tangible, beautiful reality on the lathe.