Have you ever watched a wood lathe in action? It’s fascinating to see how it turns a simple piece of wood into something beautiful. But did you know that the key to this magic lies in the chuck jaws? Understanding the wood lathe chuck jaws types can help you make better projects.

Many woodworkers struggle with choosing the right jaws for their lathe. Do you feel unsure about which type you need? Each type of chuck jaw serves a different purpose. Some are perfect for holding small pieces, while others grip larger items tightly. This opens up a world of creativity for your wood projects!

Here’s a fun fact: Did you know that some wood lathe chuck jaws can be changed easily? This lets you swap them out depending on your project. Imagine being able to shift from a bowl to a spindle without any hassle! Discovering the different types of wood lathe chuck jaws can make your turning experience much more enjoyable.

Are you ready to learn more? Join us as we dive into the various wood lathe chuck jaws types and find out which ones work best for you!

Understanding Wood Lathe Chuck Jaws Types And Their Uses

Wood Lathe Chuck Jaws Types

When you’re working with a wood lathe, understanding chuck jaws is essential. Did you know there are several types of chuck jaws? Each one serves a unique purpose. For instance, standard jaws grip round pieces, while dove tail jaws work great for bowls. There are also Pen jaws, ideal for small projects. Choosing the right type can make your projects easier and more successful. So, which type will you try next?Understanding Chuck Jaws

Definition and function of chuck jaws in woodturning.. Importance of choosing the right chuck jaws for specific projects..Chuck jaws are like strong, little hands that hold your wood in place while you work. They keep everything steady so your projects don’t go wobbly. Choosing the right chuck jaws is super important. If you pick the wrong type, your wood might fly off like a bird! Imagine trying to turn a round piece but ending up with a square one. Yikes! Always match the chuck jaws to your wood size and shape to make your work easier and more fun!

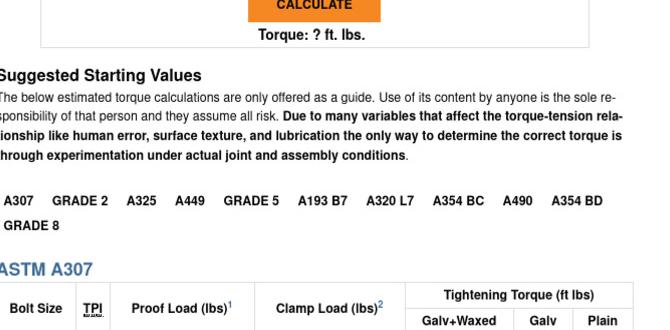

| Chuck Jaw Type | Function |

|---|---|

| Standard Jaws | Best for general turning tasks. |

| Pen Jaws | Perfect for small projects like pens. |

| Book Jaws | Great for holding larger bowls and plates. |

Key Features to Consider

Grip strength and how it affects wood stability.. Size compatibility with various lathe models..When choosing wood lathe chuck jaws, you should think about important features. Grip strength is key. Strong jaws hold your wood firmly, preventing movement. This keeps your projects stable and safe. Also, check for size compatibility. Different lathe models need different sizes. Make sure the jaws fit well with your lathe for the best results. Here are some key points to remember:

- Grip Strength: Determines wood stability.

- Size Compatibility: Ensures a perfect fit with your lathe.

Why is grip strength important?

Grip strength affects how well the wood stays in place. Stronger jaws mean less risk of slipping while working.

How do I find the right size for my lathe?

Check your lathe’s manual or specifications to find the size that works best with your chuck jaws.

Common Materials Used for Chuck Jaws

Comparison of metal vs. plastic chuck jaws.. Pros and cons of each material type..Chuck jaws come in two main player types: metal and plastic. Metal jaws are strong and durable. They grip well for heavy work. However, they can be heavy and might scratch your wood. On the other hand, plastic jaws are lighter and less likely to harm your projects. But they might not hold up under really heavy use. Let’s check out a quick comparison:

| Material | Pros | Cons |

|---|---|---|

| Metal | Strong, durable | Heavy, can scratch |

| Plastic | Light, no scratches | Less durable |

In the end, it’s all about what you need for your projects! So choose wisely and keep that wood looking good!

Maintenance Tips for Chuck Jaws

Best practices for cleaning and storing chuck jaws.. Signs of wear and when to replace jaws..Keeping your chuck jaws clean and stored properly helps them last longer. Clean them with a soft cloth after each use. Store them in a dry place to prevent rust. Watch for signs like cracks or uneven surfaces. If they aren’t gripping well, it’s time to replace them. Regular checks can save you time and money.

How can you tell if chuck jaws need replacing?

Look for signs of wear, like nicks or damaged teeth. If they can’t hold your work tightly anymore, consider replacing them. It’s better to be safe than sorry!

Frequently Asked Questions

Common queries about chuck jaw selection and usage.. Answers to troubleshooting issues related to chuck jaws..Many people have questions about choosing and using chuck jaws. What type should I use? The answer depends on your project. Different jaws fit different shapes and sizes. How can I fix my jaws if they’re stuck? Try loosening the screws gently. This often helps. Remember, always clean them after use to keep them in good shape.

Common queries about chuck jaw selection

- What size chuck jaws do I need? It depends on the wood you’re using.

- Can I use any jaw on any lathe? No, each jaw must match your lathe model.

Answers to troubleshooting issues related to chuck jaws

- Why won’t my jaws hold the wood? They may be dirty or damaged.

- How do I prevent my jaws from slipping? Ensure they’re tight, and use the right size.

Conclusion

In summary, wood lathe chuck jaws come in different types, like standard, bowl, and spigot jaws. Each type helps you grip wood pieces securely. Understanding these options makes your woodturning projects easier and more enjoyable. We encourage you to explore each type further. Try using them in your next project to see how they work for you!FAQs

Sure! Here Are Five Related Questions On The Topic Of Wood Lathe Chuck Jaws Types:Sure! Here are five types of wood lathe chuck jaws we can talk about. There are standard jaws that hold round pieces tight. You can also use pin jaws for smaller projects. Then, there are long jaws for bigger items that need extra grip. Lastly, we have multi-start jaws, which can hold different shapes. Each type helps us do different things in woodturning!

Sure! Please provide the question you would like me to answer.

What Are The Different Types Of Wood Lathe Chuck Jaws, And What Specific Applications Are They Best Suited For?Wood lathe chuck jaws hold wood safely while you work. There are different types of jaws. 1. **Standard Jaws**: These are most common. You can use them for shaping bowls or turning spindles. 2. **Reverse Jaws**: These help you grab smaller pieces of wood. They are great for doing detailed work. 3. **Step Jaws**: These can hold different shaped pieces. You can use them for larger items or when you need more grip. Each type helps you do different tasks well!

How Do The Size And Shape Of Wood Lathe Chuck Jaws Affect The Stability And Precision Of Woodturning Projects?The size and shape of wood lathe chuck jaws are important for stability and precision when turning wood. Larger jaws hold the wood more tightly, preventing it from wobbling. If the jaws are shaped well, they grip the wood evenly. This helps make smoother and more accurate turns. Good jaws make your project look better!

What Is The Difference Between Standard And Specialty Chuck Jaws In Woodturning, And When Should Each Type Be Used?Standard chuck jaws are common and great for holding most shapes of wood. You use them when you want to work on bowls or cylinders. Specialty chuck jaws have unique shapes. We use them when we need to grip odd or specific shapes, like when making small items. Choose the type based on what you’re working on!

How Can A Woodworker Properly Install And Adjust Chuck Jaws On A Wood Lathe For Optimal Performance?To install chuck jaws on your wood lathe, start by cleaning both the jaws and the chuck. Then, attach the jaws to the chuck using the screws provided. Make sure they fit snugly. Next, you can adjust the jaws by turning the handle to close or open them for different sizes of wood. Check that they grip tightly before you start turning.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Effectiveness Of Wood Lathe Chuck Jaws?To keep your wood lathe chuck jaws working well, always clean them after each use. Use a soft cloth to wipe off dirt and sawdust. You should also check for damage, like chips or cracks. Lightly oil the parts to keep them moving smoothly. Store them in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Wood Lathe Chuck Jaws Types:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five types of wood lathe chuck jaws we can talk about. There are standard jaws that hold round pieces tight. You can also use pin jaws for smaller projects. Then, there are long jaws for bigger items that need extra grip. Lastly, we have multi-start jaws, which can hold different shapes. Each type helps us do different things in woodturning!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Wood Lathe Chuck Jaws, And What Specific Applications Are They Best Suited For?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Wood lathe chuck jaws hold wood safely while you work. There are different types of jaws. 1. **Standard Jaws**: These are most common. You can use them for shaping bowls or turning spindles. 2. **Reverse Jaws**: These help you grab smaller pieces of wood. They are great for doing detailed work. 3. **Step Jaws**: These can hold different shaped pieces. You can use them for larger items or when you need more grip. Each type helps you do different tasks well!”}},{“@type”: “Question”,”name”: “How Do The Size And Shape Of Wood Lathe Chuck Jaws Affect The Stability And Precision Of Woodturning Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and shape of wood lathe chuck jaws are important for stability and precision when turning wood. Larger jaws hold the wood more tightly, preventing it from wobbling. If the jaws are shaped well, they grip the wood evenly. This helps make smoother and more accurate turns. Good jaws make your project look better!”}},{“@type”: “Question”,”name”: “What Is The Difference Between Standard And Specialty Chuck Jaws In Woodturning, And When Should Each Type Be Used?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Standard chuck jaws are common and great for holding most shapes of wood. You use them when you want to work on bowls or cylinders. Specialty chuck jaws have unique shapes. We use them when we need to grip odd or specific shapes, like when making small items. Choose the type based on what you’re working on!”}},{“@type”: “Question”,”name”: “How Can A Woodworker Properly Install And Adjust Chuck Jaws On A Wood Lathe For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install chuck jaws on your wood lathe, start by cleaning both the jaws and the chuck. Then, attach the jaws to the chuck using the screws provided. Make sure they fit snugly. Next, you can adjust the jaws by turning the handle to close or open them for different sizes of wood. Check that they grip tightly before you start turning.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Effectiveness Of Wood Lathe Chuck Jaws?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your wood lathe chuck jaws working well, always clean them after each use. Use a soft cloth to wipe off dirt and sawdust. You should also check for damage, like chips or cracks. Lightly oil the parts to keep them moving smoothly. Store them in a dry place to prevent rust.”}}]}