Wood Lathe Chuck Tightening: Essential PDF

Wood lathe chuck tightening is a critical skill for any woodturner, directly impacting the safety and quality of your work. A properly secured chuck is the foundation upon which all your turning endeavors rest. Without a firm grip on your workpiece, the risk of it flying off the lathe at high speed is not only a direct danger to the turner but can also cause irreparable damage to the lathe itself and the material being worked. This article delves into the nuances of wood lathe chuck tightening, highlighting why a comprehensive guide, particularly a wood lathe chuck tightening guide PDF, is an indispensable tool for both novice and experienced woodturners.

The importance of correct chuck tightening cannot be overstated. A chuck has a vital role: to hold your wood securely and accurately while it spins at potentially hundreds or even thousands of revolutions per minute. Whether you’re using a scroll chuck with jaws that expand or contract, a faceplate, or a screw chuck, understanding the specific mechanism and applying the correct torque are paramount. Over-tightening can strain the chuck’s internal mechanisms, leading to premature wear or even breakage. Conversely, under-tightening is the far more dangerous scenario, creating instability and an increased likelihood of a “chuck-off” incident, a terrifying and potentially catastrophic event.

Understanding Your Wood Lathe Chuck Tightening Guide PDF

The ideal resource for mastering this skill is a dedicated wood lathe chuck tightening guide PDF. These digital documents offer a readily accessible, searchable, and printable format that can be consulted directly at your workbench. Unlike a fleeting video demonstration, a PDF allows you to pause, reread sections, and refer back to specific diagrams or instructions whenever needed.

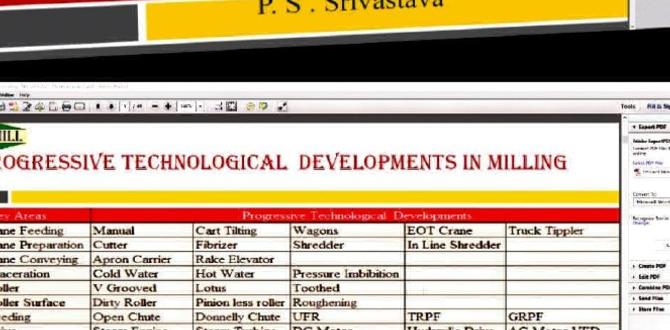

A good wood lathe chuck tightening guide PDF will typically cover several key areas. Firstly, it will detail the different types of chucks commonly found in woodturning. This might include three-jaw and four-jaw scroll chucks, their respective jaw types (e.g., wood jaws, metal jaws, pin jaws), faceplates, and screw chucks. Understanding the unique characteristics and clamping methods of each is the first step towards proficient use.

Secondly, the guide will provide step-by-step instructions on how to attach and remove the chuck from the lathe spindle. This often involves specific tools like chuck wrenches and, importantly, emphasizes the use of safety features like a cone or pin to prevent the spindle from rotating while you tighten or loosen the chuck. Forgetting this step is another common pitfall that can lead to injury or damage.

The Art of Secure Wood Lathe Chuck Tightening

The core of any wood lathe chuck tightening guide PDF will focus on the actual process of securing the wood within the chuck. This involves:

Jaw Placement and Adjustment: Ensuring the jaws, whether expanding or contracting, are correctly positioned to grip the workpiece firmly and evenly. The guide will often illustrate the optimal jaw configuration for different shapes and sizes of wood.

Applying Consistent Pressure: The importance of applying equal pressure from all jaws to maintain concentricity and prevent wobble. Uneven pressure can lead to vibration and an unbalanced turning experience.

The Role of the Chuck Wrench: Understanding how to use the supplied chuck wrench effectively. This usually involves a specific tightening sequence or pattern to ensure all jaws engage with the workpiece uniformly. Many chucks have a geared mechanism that magnifies the force applied by the wrench.

Judging Tightness: This is perhaps the subtlest but most crucial aspect. A good wood lathe chuck tightening guide PDF will offer advice on how to judge when the chuck is sufficiently tight without overdoing it. While there’s no universal “feel” that replaces experience, guides often suggest a snug yet not forced tightness. Some professionals develop a tactile sense, feeling the resistance of the chuck mechanism. Others recommend specific tightening patterns with the wrench, ensuring a consistent number of turns or a specific feeling of resistance on the final turn for each jaw.

Safety First: Integrating Guidance into Your Practice

Beyond the mechanical steps, a comprehensive wood lathe chuck tightening guide PDF will heavily emphasize safety protocols. This includes:

WearingAppropriate Safety Gear: Always donning safety glasses or a face shield, and avoiding loose clothing or jewelry before engaging with the lathe.

Pre-Turning Checks: Regularly inspecting the chuck for any signs of wear, damage, or contamination (like wood dust) that could affect its gripping ability.

Understanding Workpiece Limitations: Recognizing that even with a perfectly tightened chuck, certain wood dimensions or shapes might pose inherent risks.

Emergency Stops: Knowing the location of the emergency stop button on your lathe and being prepared to use it.

In conclusion, the seemingly simple act of wood lathe chuck tightening is a fundamental aspect of safe and successful woodturning. Investing time in understanding and practicing this skill is non-negotiable. For any woodturner serious about their craft, obtaining and thoroughly studying a reliable wood lathe chuck tightening guide PDF is an essential step. It provides the detailed, accessible, and practical information needed to ensure your workpiece remains securely attached, allowing you to focus on the creative process with confidence and peace of mind. This readily available resource will empower you to become a safer and more proficient woodturner.