Wood Lathe Collet Chuck Guide: Best Tips

When it comes to precision and versatility on the wood lathe, a wood lathe collet chuck guide can be your best friend. These specialized chucks offer a unique way to hold small, delicate, or irregularly shaped workpieces that might be challenging to grip with traditional three or four-jaw chucks. Mastering the use of a collet chuck can open up new possibilities for your woodworking projects, from intricate detail work to holding small tenons securely. This guide will walk you through the essential tips and considerations for getting the most out of your wood lathe collet chuck.

Understanding the Collet Chuck System

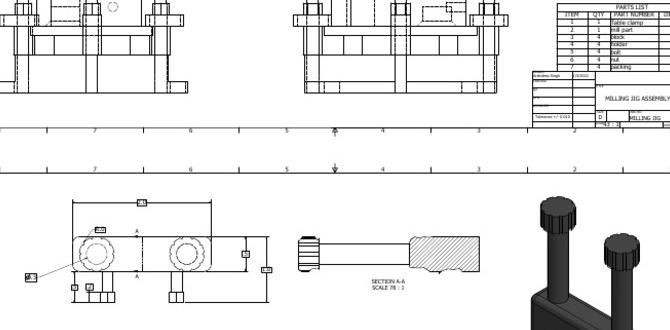

At its core, a collet chuck system consists of two main components: the collet and the chuck body. The collet is a tapered sleeve with several “slots” cut into its length. These slots allow the collet to be compressed or expanded when it’s drawn into a matching tapered socket within the chuck body. The chuck body, in turn, attaches to the lathe spindle, usually via standard threads. As you tighten the mechanism on the chuck body (often a knurled knob or a screw), it pulls the collet into its tapered seat, causing the collet to grip the workpiece held within its bore.

There are generally two types of collet chucks:

Push-Type Collets: In these systems, you place the workpiece into the collet, and then the entire collet assembly is pushed into the chuck body to engage.

Pull-Type Collets: These are more common for wood lathes. The workpiece is placed in the stationary collet, and then a mechanism on the chuck body pulls the collet into the tapered seat, creating the grip.

Understanding which type you have is crucial for proper operation and for selecting the correct collets for your needs.

Essential Tips for Using Your Wood Lathe Collet Chuck

1. Select the Right Collet for the Job:

This is perhaps the most critical aspect of using a collet chuck effectively. Collets are designed to grip within a very specific diameter range. Using a collet that is too small for your workpiece will likely result in an insecure grip and potential slippage. Conversely, forcing a workpiece into a collet that’s too large can damage the collet. Always refer to the manufacturer’s specifications for the gripping range of each collet. Most collet sets are designed for specific ranges, such as 1/8″ to 1/4″, 1/4″ to 1/2″, etc.

2. Ensure Proper Seating of the Collet:

Before you introduce your workpiece, make sure the collet is properly seated within the chuck body. Give the tightening mechanism a few turns to draw the collet in slightly and center it. This ensures that when you insert your workpiece, the collet is already in a stable position to grip it evenly.

3. Center Your Workpiece Carefully:

While collet chucks are excellent for precise holding, they don’t inherently find the center of your workpiece like a scroll chuck might. You still need to ensure your workpiece is reasonably centered within the collet’s bore before tightening. For round stock, this is less of an issue. However, for irregular shapes, you might need to make minor adjustments or use an insert within the collet if available.

4. Avoid Overtightening:

Just because a collet can grip tightly doesn’t mean you should always crank it down as hard as possible. Overtightening can deform the collet, damage the workpiece (especially soft woods or delicate turnings), and make it difficult to release later. Tighten enough to ensure a secure grip, but don’t force it. The taper and the design of the collet should provide plenty of holding power when properly engaged.

5. Keep Your Collets and Chuck Clean:

Wood dust and debris can accumulate in the fine tolerances of a collet chuck system. This can prevent proper seating of the collet and lead to inconsistent gripping. Regularly clean your collets and the interior of the chuck body with a soft cloth and, if necessary, a mild solvent. A small brush can also be helpful for dislodging stubborn dust.

6. Lubrication is Key (When Recommended):

Some collet chuck systems benefit from occasional lubrication on the tapered surfaces where the collet seats into the chuck body. Check your manufacturer’s instructions. A small amount of high-quality grease designed for metal-on-metal contact can reduce friction and wear, ensuring smoother operation and easier tightening and loosening. Avoid over-lubricating, as this can attract dust.

7. For Small Tenons, Consider a Collet Bushing:

If you frequently turn small tenons for fitting into boxes or other assemblies, a collet chuck can be ideal. However, sometimes even the smallest collet might be slightly too large for a very thin tenon. In such cases, manufacturers often offer collet inserts or bushings that can adapt standard collets to grip smaller diameters more securely.

8. Inspect for Wear and Tear:

Periodically inspect your collets for any signs of damage, such as cracks, deformation, or excessive wear on the gripping surfaces. Similarly, check the chuck body for any damage to the threads or the tapered seating area. Damaged components can compromise safety and the quality of your work.

9. Practice with Different Materials:

Get a feel for how your collet chuck performs with different types of wood and materials. Softwoods might require a gentler grip than hardwoods. Materials like resin or acrylic might be more prone to cracking if held too tightly. Experimentation and observation will help you develop an intuitive understanding of the optimal grip pressure for various situations.

Benefits of Using a Collet Chuck

The investment in a wood lathe collet chuck guide and the system itself pays off in several ways:

Precision Holding: Collet chucks inherently provide a very concentric and accurate grip on your workpiece. This is invaluable for fine detail work, tenons, and smaller components where runout is unacceptable.

Workpiece Protection: Because they grip around the circumference of a workpiece, collets distribute holding pressure evenly, minimizing the risk of marring or damaging delicate or soft materials.

Versatility for Small Stock: They excel at holding small dowels, rods, or irregularly shaped pieces that are difficult to grip effectively on larger chucks.

Quick Setup and Release: Once you get the hang of it, tightening and releasing a collet chuck can be very fast, increasing your efficiency.

By following these best tips, you can confidently incorporate a collet chuck into your woodworking arsenal, transforming how you approach smaller, more intricate, and challenging turning projects. Remember to always prioritize safety and consult your chuck’s manual for specific operating procedures.