The Precision of Woodwork: Mastering Your Craft with Wood Lathe Digital Speed Control

For any woodworker, the ability to precisely control the speed of their lathe is paramount. It’s the difference between a beautifully crafted piece and a frustrating, potentially dangerous mishap. While traditional methods of speed adjustment exist, the advent of wood lathe digital speed control has revolutionized how artisans approach their craft, offering unparalleled accuracy, consistency, and ease of use. This technology eliminates the guesswork, allowing for seamless transitions between speeds, essential for working with a vast array of wood types and executing intricate techniques.

The Evolution of Lathe Speed Management

Historically, wood lathes relied on mechanical means to alter rotational speed. This often involved stepped pulleys or complex gear trains. Adjusting the speed meant stopping the machine, physically moving belts, and restarting. This process was not only time-consuming but also prone to inaccuracies. Each “setting” offered a limited range, and fine-tuning between these fixed points was impossible. This limited the woodturner’s ability to respond dynamically to the material’s properties – harder woods might require slower speeds to prevent burning, while softer woods might benefit from higher speeds for a clean cut. The reliance on manual adjustments also introduced potential safety concerns, especially when reaching for controls while the spindle was in motion.

Embracing the Digital Advantage

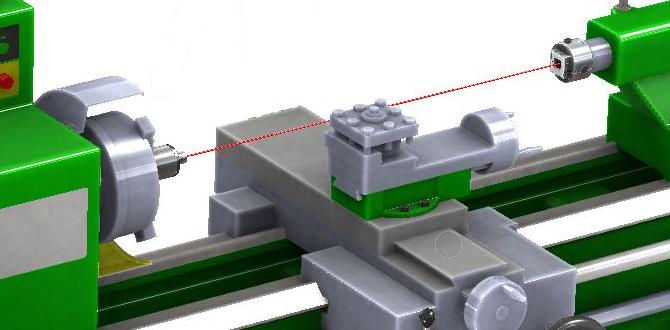

Wood lathe digital speed control fundamentally changes this paradigm. At its core, this technology replaces mechanical complexity with electronic precision. Typically, these systems utilize a variable frequency drive (VFD) or a dedicated digital controller connected to the lathe’s motor. This allows for smooth, stepless speed adjustment through a digital interface – often a dial, buttons, or even a touchscreen. The user can dial in a precise RPM (revolutions per minute) and lock it in, ensuring absolute consistency throughout the turning process.

One of the most significant benefits is the ability to make real-time speed adjustments. If you encounter a knot in the wood that causes chatter, or if you notice your chisel is burning, you can instantly reduce the speed without interrupting your workflow. Conversely, as you refine a shape and remove less material, you can incrementally increase the speed to achieve a finer finish. This dynamic control is a game-changer for achieving professional results.

Key Features and Benefits of Wood Lathe Digital Speed Control

Beyond the fundamental ability to set precise speeds, modern wood lathe digital speed control systems offer a wealth of features that enhance both functionality and safety:

Digital RPM Readout: A clear, accurate display of the current speed is perhaps the most intuitive benefit. This display provides immediate feedback, allowing you to maintain your chosen speed or make informed adjustments. Many systems even offer a “hold” function, so you can return to a previously used RPM with a single touch.

Variable Speed Range: Digital controllers typically offer a much wider and more usable speed range than their mechanical counterparts. This means you can achieve very low speeds, ideal for larger diameter bowls or delicate sanding operations, all the way up to higher speeds for smaller spindles and fine finishing.

Memory Presets: For those who frequently work with the same types of projects or materials, the ability to store specific speed settings is invaluable. You can program your preferred speeds for roughing, shaping, sanding, and finishing, and recall them instantly.

Soft Start and Stop: Many digital systems incorporate a “soft start” feature, which gradually ramps the motor up to your selected speed. This reduces wear and tear on the motor and drive system and prevents the workpiece from being suddenly jolted. Similarly, a soft stop can be programmed for a smoother deceleration.

Overload Protection: Advanced digital controllers often include built-in motor overload protection. This safety feature can automatically shut down the lathe if it detects an excessive load, preventing damage to the motor and the workpiece.

Forward and Reverse Operation: While not exclusive to digital systems, most modern digital speed controls seamlessly integrate forward and reverse functionality. This is particularly useful for sanding and finishing, allowing you to effortlessly switch directions to achieve an even smoother surface.

Integration with Other Systems: Some high-end digital speed control units can integrate with other lathe accessories, such as dust collection systems or automated tool rests, further streamlining the turning process.

Choosing the Right Wood Lathe Digital Speed Control System

When selecting a wood lathe digital speed control system, several factors are worth considering:

Lathe Compatibility: Ensure the system you choose is compatible with your lathe’s motor type and power rating. Some are universal, while others are designed for specific makes and models.

Ease of Installation: While some systems are plug-and-play, others may require more involved wiring. Consider your technical comfort level.

User Interface: The control panel should be intuitive and easy to navigate. If you prefer tactile buttons, look for those. If touchscreens appeal to you, that’s another option.

Feature Set in Relation to Your Needs: Do you need advanced memory presets, or is a simple digital readout sufficient? Match the features to your typical woodworking projects and techniques.

Brand Reputation and Support: Look for reputable manufacturers with good customer support and warranties. Reading reviews from other woodturners can provide invaluable insight.

Investing in wood lathe digital speed control is an investment in your craft. It’s a move towards greater precision, enhanced safety, and ultimately, more satisfying and rewarding woodworking experiences. By taming the rotational speed with digital accuracy, you unlock new levels of control, allowing your creativity to flow unhindered and your finished pieces to reach their full potential.