The best wood lathe with a digital tachometer offers precise speed control for safer, more consistent woodworking. This guide breaks down why it’s essential and how to choose and use one.

Ever felt a little unsure about your wood lathe’s speed? Many woodworkers, especially those just starting out, find it tricky to dial in the perfect RPM. Too fast, and you risk tear-out or worse. Too slow, and your cuts aren’t clean. A wood lathe with a digital tachometer changes all that. It puts precise speed control right at your fingertips. We’ll walk through exactly why this feature is a game-changer and help you find the right machine for your workshop.

What is a Digital Tachometer on a Wood Lathe?

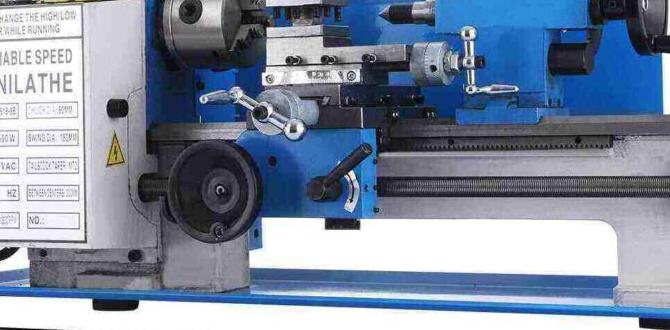

A digital tachometer is a device that precisely measures and displays your lathe’s rotational speed, usually in Revolutions Per Minute (RPM). On a wood lathe, it’s typically integrated into the control panel. Instead of guessing or relying on a dial that might not be perfectly accurate, a digital tachometer gives you a clear, numerical readout of how fast your workpiece is spinning. This is invaluable for understanding and controlling the lathe’s performance.

Think of it like the speedometer in your car. You need to know how fast you’re going to drive safely and effectively. On a lathe, knowing your exact RPM is key to performing different operations correctly and, most importantly, safely.

Why a Digital Tachometer is Essential for Woodworkers

The benefits of having a digital tachometer on your wood lathe are numerous, especially for novice woodturners. It directly addresses common frustrations and elevates your woodworking experience.

Improved Safety

Safety is paramount in any workshop, and woodturning is no exception. Different wood densities, workpiece sizes, and turning operations require different speeds. A digital tachometer allows you to:

- Avoid Over-Spinning: Turning green wood or unbalanced pieces at too high a speed can be extremely dangerous, risking the workpiece flying off the lathe. A tachometer helps you stay within safe limits.

- Select Optimal Speeds: For instance, roughing out a large spindle might require a lower RPM than finely sanding a small bowl. Accurately setting these speeds prevents accidents and frustration.

- React to Material Changes: If you notice chatter or vibration, you can quickly check and adjust the speed for a safer, smoother operation. Consistent speed control is a significant safety factor in avoiding kickback and workpiece ejection.

Enhanced Precision and Quality

Consistency is the hallmark of quality woodworking. A digital tachometer is your partner in achieving just that:

- Reproducible Results: Once you find the perfect speed for a specific cut or finish on a particular type of wood, you can replicate it exactly. This is invaluable for making matching parts or achieving consistent finishes.

- Better Cuts: Different woods and different turning tasks benefit from specific RPMs. For example, turning a very soft wood might require a slower speed than a dense hardwood to avoid tear-out. A tachometer lets you set these precisely.

- Smoother Finishes: As you get into sanding, particularly at higher speeds, a precise RPM allows for a smoother, more even abrasive action, leading to a professional finish without the risk of burning or uneven sanding.

Easier Learning Curve

For beginners, the sheer number of variables can be overwhelming. A digital tachometer simplifies one of the most critical aspects of lathe operation:

- Confidence Building: Knowing your exact speed removes a layer of guesswork and anxiety, allowing new woodturners to focus on their technique.

- Understanding Wood Properties: As you gain experience, you’ll learn to associate certain speeds with specific woods and operations. A tachometer helps you build this knowledge base faster.

- Efficient Operation: No more fiddling with belts or speed dials hoping for the right setting. You can quickly dial in the correct RPM and get to work.

Versatility for Different Projects

Wood lathes aren’t just for spindles. Whether you’re turning bowls, platters, or intricate decorative pieces, the ability to precisely control speed opens up possibilities:

- Bowl Turning: Large diameter bowls require slower speeds than smaller ones for safety. A digital tachometer ensures you’re within safe operating ranges.

- Propeller Work: For very large or out-of-balance pieces, slower speeds are crucial, and a tachometer guarantees this.

- Detail Work: While often done at higher speeds, precise control allows for delicate carving or shaping without overwhelming the wood.

Choosing a Wood Lathe with a Digital Tachometer

When you’re looking to purchase a wood lathe that features a digital tachometer, consider these key aspects to ensure you get a machine that fits your needs and budget.

Motor Power and Speed Range

The motor determines what you can do with the lathe. Look for a motor size that matches your typical projects. Larger motors (higher horsepower) are better for larger workpieces and hardwoods. The speed range is also vital. A wider speed range, controlled accurately by the digital tachometer, offers more versatility.

Typical Considerations:

- Beginner/Hobbyist: 1/2 HP to 1 HP motor, speed range from 500 RPM to 3000+ RPM.

- Intermediate: 1 HP to 2 HP motor, wider speed range for more demanding tasks.

- Advanced/Professional: 2 HP and above, often with more robust speed control and higher torque at lower RPMs.

Variable Speed Control

A digital tachometer is most effective when paired with good variable speed control. This allows you to adjust the speed smoothly across the entire range, usually via a dial or buttons directly linked to the tachometer display. This electronic variable speed (EVS) is a significant upgrade from belt-driven speed changes.

Lathe Construction and Stability

A sturdy lathe is a safe lathe. Look for:

- Bed Material: Cast iron is preferred for its vibration-dampening qualities and stability.

- Headstock and Tailstock: These should be robust and securely lock to the bed. The headstock often houses the motor and drive mechanism.

- Overall Weight: Heavier lathes tend to be more stable and reduce vibration, leading to better cuts and finishes.

For more about lathe construction, the Forest Products Laboratory has detailed information on wood lathe design and operation principles.

Features to Look For

- Digital Display Readout: Clear, easy-to-read RPM display is the core feature.

- Forward/Reverse Switch: Allows you to turn the workpiece in the opposite direction, which is beneficial for certain finishing techniques like shear scraping.

- Tool Rest: Ensure it’s robust, easy to adjust, and locks securely. Adjustable rests are essential for different workpiece diameters and turning angles.

- Swinging Headstock: Some lathes allow the headstock to pivot, making it easier to swing larger bowls between the centers.

- Extension Beds/Outboard Turning: If you plan on turning large bowls, consider lathes that can be extended or have capabilities for outboard turning.

Budget

Lathes with digital tachometers often fall into the mid-to-higher price range compared to basic belt-driven models. However, the increased safety, precision, and versatility are often well worth the investment for serious hobbyists and aspiring professionals.

Using Your Wood Lathe with a Digital Tachometer: A Step-by-Step Guide

Operating a wood lathe with a digital tachometer is an intuitive process once you understand the basic steps. Here’s how to get started safely and effectively.

Step 1: Prepare Your Lathe and Workspace

- Ensure the lathe is on a stable, level surface.

- Check that the power cord is in good condition and properly grounded.

- Clear the area around the lathe of any clutter.

- Make sure you have appropriate safety gear: safety glasses or a face shield, hearing protection, and a dust mask.

Step 2: Mount Your Wood

This is a critical safety step. There are several ways to mount wood:

- Between Centers: For spindle turning, use a drive center at the headstock end and a live or spur center at the tailstock end. Ensure the wood is securely seated and the tailstock is locked.

- Faceplate: For bowl turning, the wood is attached to a faceplate, which then screws onto the lathe’s spindle. Ensure the faceplate is securely attached to both the wood and the spindle.

- Face of the Headstock Spindle: Smaller projects or jigs can sometimes be mounted directly.

Important: For initial mounting, especially with irregular blanks, it’s wise to use a significantly lower RPM than you might eventually use. Some woodworkers recommend “coning” the blank – turning it round at a very slow speed before increasing RPM.

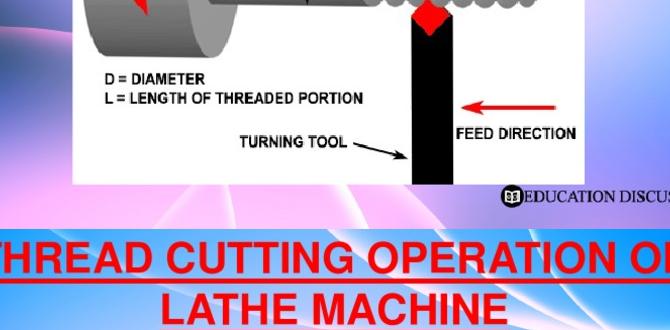

Step 3: Set Initial Speed Using the Digital Tachometer

This is where your digital tachometer shines.

- Turn on the lathe at its lowest speed setting.

- Observe the Digital Display: The RPM will appear on the digital tachometer.

- Adjust the Speed: For a roughing-out phase, especially with newly mounted wood, start very slow. Many beginners aim for 500-800 RPM, but this can vary based on wood and workpiece size. For example, a large, potentially unbalanced bowl blank is riskier at high speeds.

As a general rule of thumb for safety, especially when starting with a new piece of wood:

Roughing Spindle Turning: 700-1200 RPM

Roughing Bowl Turning: 500-900 RPM (for larger diameters, go slower)

Fine Shaping: 1000-2000 RPM (depending on wood and tool)

Sanding: 1500-2500+ RPM (depending on grit and wood)

Always consult guides or experienced turners and use your judgment. Resources like Woodworking Network provide excellent safety advice.

Step 4: Perform Your Turning Operation

With the workpiece spinning at a safe and appropriate speed:

- Engage your cutting tool gently against the wood.

- Listen to the lathe and feel for vibrations. Any excessive noise or shaking is a sign to stop, check your mounting, and potentially lower the speed.

- Gradually increase speed as the workpiece becomes rounder and more balanced, and as you move to finer cuts. Adjust the speed using the controls linked to the digital tachometer.

- Keep your tool rest close to the workpiece for safety and control.

Step 5: Adjust Speed for Different Tasks

As you progress from roughing to shaping, hollowing, and finally sanding:

- Roughing: Start slow, increase speed slightly as it becomes more balanced.

- Shaping: You might increase speed for more efficient cuts, but ensure the wood is balanced and the cut is smooth.

- Sanding: Higher speeds generally provide a better sanding finish, but always ensure the wood and lathe can handle it smoothly. Lowering the speed can sometimes be better for very fine grits or delicate areas.

The digital tachometer makes these transitions seamless. Just dial in the desired RPM and continue working.

Step 6: Finishing and Cleanup

Once your turning is complete, and before turning off the lathe entirely:

- Lower the speed to a safe level for applying any finishes if necessary.

- Turn off the lathe and wait for it to stop completely before removing the workpiece or any tools.

- Clean your lathe and the surrounding area.

Advanced Techniques and Tips

Once you’re comfortable with the basics, a digital tachometer opens up more possibilities and helps refine your skills.

Using Forward and Reverse

Many modern lathes with digital tachometers also feature a forward and reverse switch. This is incredibly useful for specific operations, especially finishing and sanding.

- Shear Scraping: Using a scraper turned at a negative rake angle can create a very smooth surface. Holding the scraper so it cuts on the bevel can produce a glass-smooth finish, particularly effective when used in the reverse direction at lower speeds.

- Sanding: Running the surface in reverse at a moderate speed can help knock down swirl marks left by forward sanding or application of finishes.

- Directional Finishes: Some finishes can be applied more effectively when working with or against the grain direction, which can be controlled with the lathe’s direction and speed.

Always check your lathe’s manual to ensure it’s designed for frequent direction changes and what speeds are recommended.

Understanding Torque vs. Speed

While a digital tachometer tells you the speed (RPM), it doesn’t directly tell you about torque (rotational force). In general:

- Low RPM + High Torque: Good for roughing large, unbalanced pieces or hardwoods where you need a lot of power to move material without stalling.

- High RPM + Low Torque: Good for light cuts, fine shaping, and sanding where speed is more important than brute force.

Electronic variable speed lathes are designed to offer a good balance across their range, but understanding this relationship helps you choose the right speed for the job.

Using RPM Charts and Formulas

While your tachometer provides the actual RPM, it’s still useful to know general guidelines. Many woodturners use charts based on workpiece diameter to determine safe starting speeds. A common rule of thumb is the “Peripheral Speed” rule, though precise RPM is easier with a tachometer. For example, a common starting point for roughing a 10-inch bowl might be around 500-700 RPM.

For more in-depth information on lathe speed calculations and safety, the Occupational Safety and Health Administration (OSHA) offers regulations and guidance on woodworking machinery, including lathes, which often touch on safe operating speeds.

Troubleshooting Common Issues

Vibration: This is the biggest enemy of good turning. It can be caused by:

- Unbalanced workpiece.

- Loose mounting of the workpiece.

- Loose headstock or tailstock.

- Bed that isn’t stable.

- Tool rest too far from the workpiece.

- Speed too high for the diameter/balance.

Always check and lower the speed if vibration is excessive.

Burning: Often caused by tool digging in too aggressively, or sometimes by sanding at too low a speed with the wrong grit, or at too high a speed with the wrong technique. Adjusting cutting angle or sanding technique, possibly with a slight speed adjustment, can help.

Pros and Cons of Wood Lathes with Digital Tachometers

Like any tool feature, a digital tachometer has its advantages and disadvantages.

Pros:

- Precision: Accurately know and control RPM.

- Safety: Easily set and maintain safe speeds based on workpiece.

- Consistency: Reproduce desired speeds for projects.

- Ease of Use: Simplifies speed selection, especially for beginners.

- Versatility: Optimal for various turning tasks and wood types.

- Modern Features: Often found on lathes with other desirable electronic variable speed features.

Cons:

- Cost: Lathes with digital tachometers are generally more expensive than basic models.

- Complexity: Electronic components can fail, though this is rare with quality machines.

- Power Dependency: Requires a power source to display speed.

Comparison Table: Basic Lathe vs. Lathe with Digital Tachometer

Here’s a quick comparison to highlight the differences:

| Feature | Basic Belt-Driven Lathe | Lathe with Digital Tachometer |

|---|---|---|

| Speed Adjustment | Manual belt shifting between pulleys (limited, discrete steps) | Electronic variable speed with precise dial/button control |

| Speed Display | Usually a printed chart, often inaccurate or no display | Clear, digital numerical readout (RPM) |

| Precision Control | Low; relies on judgment and positioning belts. | High; exact speeds can be selected and maintained. |

| Safety | Relies more on user experience and caution. |