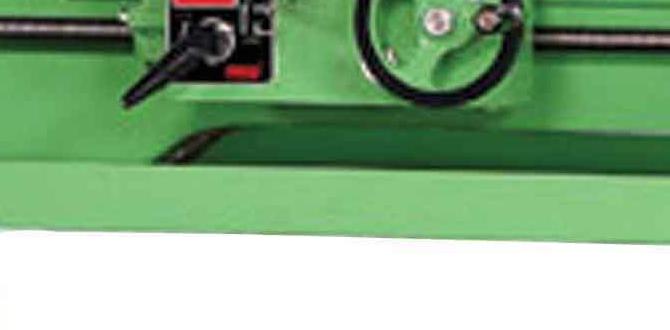

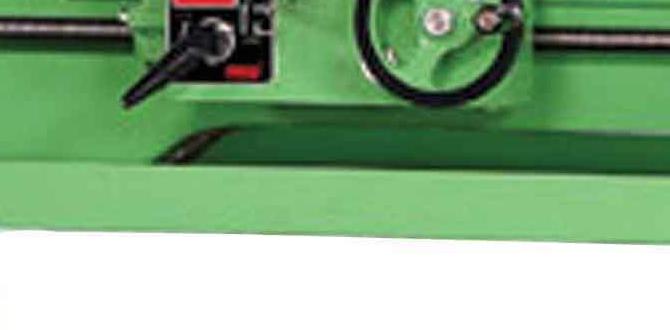

Wood lathe drive spurs are fundamental components of any woodturning operation, acting as the crucial link between your lathe’s motor and the piece of wood you’re shaping. Their primary function is to grip the workpiece securely, allowing it to rotate uniformly and withstand the forces applied by cutting tools. Without the right drive spur, your turning projects could be unstable, inaccurate, and even dangerous. Understanding the various wood lathe drive spur types available is paramount for woodworkers seeking precision, efficiency, and safety in their craft.

The drive spur might seem like a simple piece of metal, but its design and application significantly influence the outcome of your work. From small, intricate bowls to large, imposing table legs, the demands placed on a drive spur vary. Choosing the correct type for the job ensures optimal grip, minimizes workpiece damage, and facilitates smooth and controlled turning. This article will delve into the essential wood lathe drive spur types, exploring their unique characteristics, ideal applications, and considerations for selecting the best fit for your needs.

The Standard Drive Spur: Workhorse for General Turning

The most common and recognizable wood lathe drive spur type is the standard spur. This typically features a pointed metal tooth or teeth that are hammered or pressed into the end grain of the wood. The angle and sharpness of these teeth are designed to bite into the fibers, providing a secure rotational force.

Design: Standard spurs come in various sizes and with different numbers of teeth, ranging from a single point to multiple prongs. Single-point spurs are generally used for smaller, lighter pieces where minimal marring is desired, while multi-point spurs offer a more aggressive grip for larger or heavier workpieces.

Application: These are the go-to for general turning tasks, including spindle turning (legs, finials, rails) and faceplate turning for bowls and platters. They are particularly effective when working with solid wood where the grain provides sufficient resistance for the spur to bite into.

Considerations: When using a standard spur, it’s vital to ensure the wood is sufficiently seasoned and dry. Green wood can deform, potentially loosening the spur’s grip. Care must also be taken not to over-hammer the spur, which can damage or split the wood, especially at the end grain. The spur’s location is also important; ideally, it should be driven into an area that will eventually be removed or is less critical to the final aesthetic. Impact from the spur can create a small indentation that may need to be planed or sanded away.

Screw-In Drive Spurs: Easy Insertion and Reliable Grip

Screw-in drive spurs offer a convenient and robust alternative to hammered-in types. As their name suggests, they feature a threaded shank that is screwed directly into a pre-drilled hole in the workpiece. This method provides a very secure and consistent grip, often preferred for its ease of use and reduced risk of damaging the wood.

Design: These spurs usually have a central point or a few sharp teeth surrounding a screw or pilot hole. The threading is designed to draw the spur firmly into the wood. They are often made of hardened steel for durability.

Application: Screw-in spurs are excellent for a wide range of turning, from small craft items to larger projects. They are particularly useful when turning smaller pieces made from denser hardwoods, where hammering a standard spur might be difficult or could risk splitting the material. They are also a good choice for users who may not have the strength or practice for effectively hammering in a standard spur.

Considerations: A pilot hole is essential for screw-in spurs. The size of the pilot hole needs to be appropriate for the spur’s threads – too small and you risk the wood splitting, too large and the threads won’t get a good purchase. Many woodturners recommend drilling a pilot hole slightly smaller than the root diameter of the screw thread for optimal grip. They are also generally easier to remove cleanly than hammered spurs.

Live Centers and Drive Dogs: Versatile Solutions for Specific Needs

While not always categorized strictly as “drive spurs,” live centers and drive dogs serve a similar purpose – to engage with the workpiece for rotation. They offer distinct advantages and are essential tools in a woodturner’s arsenal.

Drive Dogs: For Faceplate Work and Beyond

Drive dogs are a bit different. Instead of biting into the wood directly, they typically clamp onto the edge of the workpiece, often in conjunction with a faceplate.

Design: Drive dogs usually consist of a metal body that attaches to the lathe’s faceplate or a faceplate alternative. They have protruding points that dig into the face of the wood, or they may grip the edge. Some designs use a screw to tightly clamp the dog onto the workpiece.

Application: Drive dogs are ideal for turning irregularly shaped pieces or when you need to work on the end grain without deeply embedding a spur. They are frequently used for turning square stock or other non-round starting materials where a traditional spur might not have a clean surface to grip initially. They are also excellent for situations where you want to minimize damage to the workpiece’s end grain.

Considerations: Using drive dogs often requires a faceplate or a specialized chuck for mounting. The wood needs to be thick enough to accommodate the drive dog’s grip without compromising its structural integrity. Proper alignment is crucial to ensure balanced rotation.

Live Centers: Support and Reduced Strain

A live center is mounted in the tailstock and provides a point of support for the workpiece. While it doesn’t directly drive the rotation, it works in tandem with a drive spur mounted on the headstock.

Design: A live center consists of a bearing that allows a pointed spindle to rotate freely. This spindle engages with the end of the workpiece, providing steady support without the friction of a dead center.

Application: Live centers are invaluable for turning long, slender spindles or large, heavy bowls. They prevent drooping and whipping of the workpiece, leading to more accurate cuts and a smoother finish. When used with a drive spur, the spur provides the rotational force, and the live center keeps the other end stable.

Considerations: The live center’s point should be accurately centered with any drive spur. It needs to be firmly seated in the tailstock and adjusted to apply just enough pressure to support the wood without deforming it or causing undue strain.

Choosing the Right Drive Spur for Your Project

Selecting the correct wood lathe drive spur type is a decision that depends on several factors:

1. Wood Type and Condition: Softer woods may require fewer or less aggressive teeth, while hardwoods benefit from more robust engagement. Green wood is more prone to deforming, so secure gripping is paramount.

2. Workpiece Size and Weight: Larger and heavier pieces demand drive spurs that can provide a strong, reliable grip to prevent slippage.

3. Turning Operation: Spindle turning often calls for different spurs than faceplate turning. Intricate or delicate work might necessitate spurs that cause minimal indentation.

4. Desired Finish: If the end grain of your workpiece is intended to be part of the final aesthetic, you’ll want a spur type that minimizes damage.

5. Ease of Use and Security: For beginners or those seeking convenience, screw-in spurs or drive dogs can be excellent options.

In conclusion, the world of wood lathe drive spurs is surprisingly diverse, offering specialized solutions for a wide array of turning challenges. From the classic hammered-in standard spur to the convenient screw-in type and the supportive live center, each plays a vital role. By understanding the strengths and applications of each wood lathe drive spur type, woodturners can enhance the precision, safety, and overall quality of their creations, ensuring that their lathe truly becomes an extension of their artistic vision.