Effortless setup is often the holy grail for workshop enthusiasts, and when it comes to managing wood dust, a wood lathe dust hood homemade solution can truly unlock that ease. The fine particles that erupt from turning wood can quickly fill your workspace, posing health risks and making cleanup a Sisyphean task. However, with a bit of ingenuity and readily available materials, you can construct a dust collection system that effectively captures these airborne irritants without breaking the bank or demanding advanced woodworking skills. This article will guide you through understanding the benefits of a dust hood, exploring different design approaches, and ultimately empowering you to build your own effortless wood lathe dust hood homemade system.

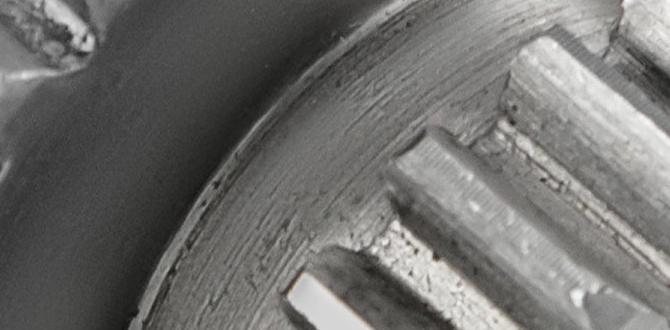

The benefits of a well-designed dust hood extend far beyond a cleaner workshop. Firstly, and most critically, is the significant improvement in air quality. Wood dust, especially from certain hardwoods, can contain volatile organic compounds (VOCs) and microscopic particles that, when inhaled, can lead to respiratory problems, allergies, and even long-term health issues. A dust hood acts as a primary defense, capturing a substantial portion of this dust at its source before it can disperse into the air you breathe. Secondly, a cleaner workshop translates to less cleanup time. Instead of spending hours vacuuming and dusting, you’ll find yourself with a significantly reduced mess, allowing you to focus more time on the creative process of woodturning itself. Lastly, a dust hood can also protect your lathe and other workshop equipment from accumulating a fine layer of dust, which can interfere with moving parts and potentially cause rust.

Designing Your Wood Lathe Dust Hood Homemade Solution

The beauty of a homemade dust hood lies in its adaptability. You don’t need professional blueprints or specialized tools. The core concept is simple: create an enclosure around the turning workpiece that can channel the dust towards a collection point. Several effective designs are popular among woodturners.

One of the simplest yet remarkably effective approaches is the bag-style dust hood. This typically involves a large, clear plastic bag (like a storage bag or a heavy-duty trash bag) that is strategically cut and shaped to enclose the area around the lathe’s headstock and the turning blank. An opening is cut to allow for tool access, ensuring you can still comfortably work. The bag is then connected to your dust collection system’s hose, usually via a cardboard tube or a piece of PVC pipe secured with tape or a hose clamp. The clear nature of the bag allows you to easily see your work, and its flexibility means it can adapt to various workpiece sizes. The key to making this effortless is finding a way to temporarily secure the bag to the lathe without it shifting excessively during operation. Magnets, adjustable straps, or even simple clamps can be employed for this purpose.

Another popular and often more robust option is the cardboard or plywood dust hood. This design offers greater rigidity and durability. Essentially, you’re constructing a box or a partial enclosure that fits around the turning area. For a cardboard version, sturdy corrugated cardboard boxes can be cut and taped together to form the desired shape. For a more permanent solution, thin plywood or MDF can be used. The base of the hood often rests on the lathe bed or is suspended from above, with an opening for tool access. A port is incorporated into the design to connect your dust collection hose. When building this wood lathe dust hood homemade system, remember to consider ventilation. While you want to capture dust, completely sealing the area can make it difficult to see your work and can also hinder consistent airflow. Leaving a small gap or a carefully placed vent can improve visibility and dust collection efficiency.

Integrating Your Homemade Dust Hood with Dust Collection

The true effectiveness of any dust hood hinges on its connection to a dust collection system. This could be a dedicated shop vacuum, a powerful dust collector, or even a robust shop-grade vacuum cleaner for smaller operations. The key is to have sufficient airflow to draw the dust into the collection system.

When connecting your wood lathe dust hood homemade creation to your dust collection, ensure a tight seal. Any gaps will allow dust to escape, diminishing the system’s effectiveness. Duct tape is a woodturner’s best friend here, providing a quick and reliable way to seal connections between hoses, ports, and your homemade hood. Consider the diameter of your dust collection hose. While larger hoses generally offer better airflow, you might need to adapt smaller hoses to your hood design. Reducing adapters or creatively fashioned cardboard sleeves can help bridge these gaps.

It’s also worth noting that even the most effective dust hood will not capture 100% of the dust. Some fine particles will inevitably escape. Therefore, a good wood lathe dust hood homemade system should be complemented by other dust mitigation strategies. This includes wearing a high-quality dust mask or respirator, keeping the workshop swept and clean, and perhaps even investing in an air filtration unit for continuous air cleaning.

Effortless Operation and Maintenance

An effortless wood lathe dust hood homemade solution isn’t just about ease of construction; it’s also about ease of use and maintenance. Once built, setting up and taking down your dust hood should be a quick and simple process. For bag-style hoods, this might involve just a few seconds to position and secure the bag. For more rigid designs, consider incorporating quick-release mechanisms or a system that easily lifts out of the way when not in use.

Maintenance is minimal for most homemade dust hoods. Regularly check for and repair any tears or leaks in your bag or cardboard design. For plywood or MDF hoods, a quick wipe-down to remove accumulated dust is usually sufficient. The most important aspect of maintenance will be to ensure your dust collection system itself is functioning optimally – emptying vacuum bags or dust collector bins regularly to maintain consistent suction.

In conclusion, creating a wood lathe dust hood homemade system is an achievable and highly beneficial project for any woodturner. By understanding the principles of dust capture and employing simple materials and designs, you can dramatically improve your workshop’s air quality, reduce cleanup time, and make your woodworking experience more enjoyable and healthier. The “effortless” aspect comes not only from the straightforward construction but also from the ease with which a well-made dust hood integrates into your turning workflow, allowing you to focus on the art of shaping wood rather than battling the dust.