This guide reveals how to properly set up your wood lathe tool sharpening jig for razor-sharp tools. Achieve perfect bevels and extend tool life with these easy steps.

Ever feel like your wood lathe tools are fighting you, leaving rough cuts and frustrating grooves? You’re not alone! Dull tools are a common pain point for woodturners, especially those just starting out. They make simple tasks feel impossible and can even be dangerous. But what if I told you the secret to consistently sharp tools lies not just in the sharpening stone, but in how you set up your sharpening jig? Getting your jig right is the “proven essential” step that makes all the difference. Today, we’ll walk through exactly how to set up your wood lathe tool sharpening jig, turning those frustrating sessions into smooth, confident turning.

Why Proper Jig Setup is Crucial for Wood Lathe Tools

Think of your sharpening jig as the guiding hand for your tool against the sharpening stone or wheel. If that hand is unsteady, at the wrong angle, or just not positioned correctly, you’re going to end up with a tool that’s not sharp, or worse, one that’s been ground incorrectly. This can lead to a ruined tool edge and a lot of wasted effort. For beginners, this is where a lot of confusion and discouragement can creep in. You might spend ages grinding, only to find the tool still isn’t performing. That’s why mastering your jig setup is so important. It’s the foundation for all effective tool sharpening.

A correctly set up jig ensures consistency. It means every time you sharpen a particular tool bevel, you’re hitting the same angle. This consistency is key to developing a clean, effective cutting edge that lasts. It also makes the whole process much faster and more predictable. You’ll know what to expect, and you’ll be able to replicate those perfect results again and again. This builds confidence and allows you to focus on your turning, not on fighting with dull tools.

Understanding the Basics of Wood Lathe Tool Sharpening

Before we dive into jig setup, let’s quickly touch upon the core principles of sharpening wood lathe tools. Most woodturning tools have a primary bevel, which is the main angled surface that does the cutting. The goal of sharpening is to restore or create a very fine, sharp edge at the apex of this bevel. For most woodturning chisels and gouges, this involves grinding the bevel to a specific angle and then honing the very tip to a mirror-like polish.

Common Wood Lathe Tool Types and Their Bevel Angles

Different tools require different bevel angles for optimal performance. Here’s a general guide:

- Spindle Gouges: Typically sharpened to between 35 to 45 degrees. A finer angle allows for delicate cuts, while a slightly steeper angle offers more durability.

- Bowl Gouges: Common angles range from 40 to 60 degrees. Higher angles (like 55-60 degrees) are great for roughing out bowls and cutting end grain, while lower angles offer a cleaner shearing cut on face grain.

- Skew Chisels: These are a bit more complex. They can be sharpened to different angles depending on their intended use, commonly between 30 to 45 degrees. The flat of the bevel is what contacts the wood.

- Scrapers: Often sharpened to a very narrow, almost perpendicular angle, or they might have a small burr formed at the edge for scraping.

It’s important to note that these are general guidelines. Some woodturners develop preferences based on the types of wood they work with or the specific effects they want to achieve. Experimentation is part of the learning process!

The Importance of the Bevel Angle

The bevel angle dictates how the cutting edge interacts with the wood. A steeper angle (higher number) generally provides a stronger edge that is less prone to chipping, making it good for aggressive cuts or working with figured woods. A shallower angle (lower number) creates a keener edge that can shear through the wood more cleanly, often preferred for fine finish cuts. If your bevel angle is wrong, the tool won’t cut effectively, it’ll tear the wood, or it will simply push its way through without removing material.

Essential Components of a Wood Lathe Tool Sharpening Jig

Sharpening jigs come in various forms, but they generally share a few key components designed to hold the tool at a precise angle. Understanding these parts will help you set up any jig effectively.

Common Jig Components

- Tool Rest/Holder: This is where your tool actually sits or is clamped. It needs to be sturdy and allow for adjustments.

- Angle Adjustment Mechanism: This is the critical part that allows you to set the precise bevel angle. It might be a graduated scale, a series of adjustable stops, or a sliding component.

- Stop Collar or Locking Mechanism: Used to secure the tool in the desired position once the angle and depth are set.

- Base/Mounting System: How the jig attaches to your grinding wheel or sharpening system. This needs to be stable.

Types of Sharpening Jigs

While the core function is the same, you’ll encounter different types of jigs:

| Jig Type | Description | Best For |

|---|---|---|

| Universal Grinding Jigs (e.g., Wolverine Grinding Jigs) | These are versatile jigs that often use a ‘tanto’ style guide to pivot your tool’s bevel against the grinding wheel. They are highly adaptable for most gouges and chisels. | Beginners and intermediate woodturners needing a reliable all-rounder for various tools. |

| Shaft-Style Jigs | These jigs hold the tool by its shaft and extend it towards the grinding wheel. They are very stable and offer excellent control for precise angles on chisels and scrapers. | Sharpening flat-ground tools like scrapers, skew chisels, and bench chisels. |

| Specialty Jigs | Designed for very specific tools or sharpening methods, like jigs for fingernail gouges or jigs that hold the tool at a fixed angle for a specific grind. | Turners with specific tools or those who prefer a highly specialized sharpening setup. |

Setting Up Your Jig: A Step-by-Step Guide

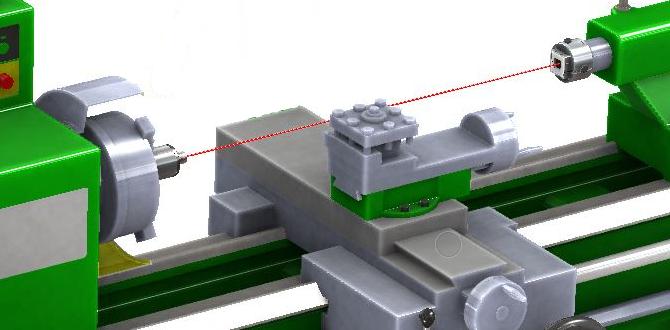

The exact steps will vary slightly depending on your specific jig and sharpening system (bench grinder with sharpening wheels, Tormek, Work Sharp, etc.), but the fundamental principles of setting the angle and depth remain the same. We’ll focus on a common setup using a universal grinding jig that pivots. This is a great starting point for most beginners.

Step 1: Identify Your Target Bevel Angle

This is the most crucial first step. What angle do you want for this specific tool? Refer back to the common angles listed earlier, or check the manufacturer’s recommendations for your tool.

- For a bowl gouge, maybe you’re aiming for 55 degrees for roughing.

- For a spindle gouge, 35 degrees for delicate work.

- For a skew chisel, 40 degrees is a good starting point.

If you’re unsure, 40-45 degrees is a versatile angle for many general-purpose tools and can be a safe bet when starting out.

Step 2: Set the Jig’s Angle Mechanism

Most jigs have a way to dial in the angle. This might involve:

- Reading a Scale: Many jigs have a calibrated scale or indicator. You’ll simply align the indicator or pointer with your desired angle mark.

- Using Angle Gauges or Templates: Some systems require you to use a separate tool, like an angle gauge (often a digital angle finder or a simple protractor), to set the jig precisely. You might place the angle gauge on the jig’s rest or guide and adjust until it reads your target angle.

- Pre-Set Stops or Notches: Simpler jigs might have pre-defined notches or stops for common angles (e.g., 30, 45, 60 degrees).

If you have a Tormek or similar water-cooling grinder, their jigs attach to a specific grinding rest, and the angle is often set by adjusting the height of the rest, guided by a reference mark on the jig. Always refer to your jig’s manual for its specific adjustment method. For instance, the Tormek system is widely praised for its ease of setup, and their guides for setting common bevel angles are excellent resources. You can find detailed guides on their website, like this overview of their jig system: https://www.tormek.com/international/en/jigs/

Step 3: Position the Grinding Wheel

This is crucial. The sharpening surface (grinding wheel or stone) needs to be at the correct height relative to your jig’s tool rest.

- Bench Grinder: The jig typically rests on the tool rest of the grinder. You might need to adjust the tool rest’s height or angle slightly. The goal is for the sharpening wheel to make contact with the bevel at the point determined by your jig’s angle setting.

- Water-Cooling Grinders (e.g., Tormek): These often have a dedicated universal support arm. You adjust the height of this arm so that when the tool is placed in the jig and against the stone, the stone contacts the bevel at the correct point.

A common mistake is to have the grinding wheel too high or too low relative to the jig’s guide. This will force the tool into an incorrect angle, defeating your careful jig setup.

Step 4: Prepare and Insert the Tool

Before inserting your tool, it’s a good idea to:

- Clean the Tool: Remove any wood debris or old grinding dust.

- Identify the Bevel: Locate the bevel angle that you want to sharpen on your tool.

- Insert into Jig: Slide