Wood lathe tool sharpening machines are essential for keeping your turning tools razor-sharp, ensuring cleaner cuts, safer operation, and a more enjoyable woodworking experience. Investing in the right sharpening setup dramatically improves your results and extends the life of your valuable tools.

Ever started a woodworking project, only to have your tools snag, tear, or refuse to cut cleanly? It’s a frustrating experience, especially when you’re just getting the hang of your wood lathe. The culprit is often dull tools. But don’t worry, this is a common challenge for beginners, and thankfully, a straightforward solution. Keeping your wood lathe tools sharp is not just about ease of use; it’s crucial for safety and the quality of your finished pieces. In this guide, we’ll demystify the world of wood lathe tool sharpening machines and show you exactly why they are a proven essential for any woodturner.

Why Sharp Wood Lathe Tools Are Non-Negotiable

When your gouges, chisels, and scrapers are sharp, they glide through the wood, leaving a smooth, finished surface. This means less sanding later on, saving you precious time and effort. More importantly, dull tools require more force to cut. This increased pressure can cause the tool to dig in unexpectedly, leading to catches, gouges in your workpiece, and even serious injury. Think of it like trying to cut with a butter knife versus a sharp chef’s knife – the difference is night and day, and the safety implications are massive.

A sharp edge acts like a scalpel, removing thin shavings of wood with precision. A dull edge, on the other hand, tears and crushes the wood fibers. This not only looks bad but also weakens the wood, making it more prone to splintering and cracking. For beginners, learning to control the tool is challenging enough; doing so with a dull edge adds an unnecessary layer of difficulty and danger.

The goal of woodturning is to shape wood with control and finesse. Sharp tools are your best allies in achieving this. They allow for effortless cuts, consistent results, and a much more forgiving turning experience. Mastering sharpening is as important as mastering the lathe itself. It’s a skill that pays dividends immediately and throughout your woodworking journey.

Understanding Different Wood Lathe Tool Sharpening Machines

There are several types of machines and methods used to sharpen wood lathe tools. Each has its own advantages and is suited for different needs and budgets. Let’s explore the most common ones you’ll encounter.

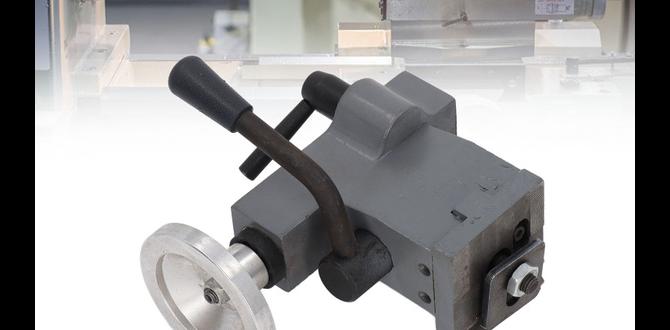

1. Grinders with Sharpening Jigs

This is arguably the most common and versatile setup for beginners and experienced turners alike. It typically involves a bench grinder (often a slow-speed grinder, which is preferred for turning tools to prevent overheating the steel) and specialized jigs designed to hold your tools at the correct angles for sharpening.

Bench Grinder: These are standard workshop tools. For woodturning, it’s highly recommended to use a slow-speed grinder (1700-1800 RPM). High-speed grinders (3400 RPM) can easily overheat and damage the temper of your tool steel, making it softer and less able to hold an edge. Look for grinders with at least an 8-inch wheel diameter for better control and less wobble. Water-cooled grinders are also excellent as they further reduce the risk of overheating and can also help control dust.

Sharpening Jigs: These are crucial for achieving consistent and correct bevel angles. Without a jig, it’s incredibly difficult to hold a turning tool against the grinding wheel at the precise angle needed for optimal cutting. Common jigs include:

- Gouges and Skew Jigs: These hold your gouges (bowl, spindle) and skew chisels, allowing you to accurately present the bevel to the grinding wheel. They guide the tool along the wheel at a controlled angle, ensuring a uniform bevel.

- Scraper Jigs: These are designed specifically for scrapers, helping you maintain the correct sharpening angle on their flat or slightly curved faces.

- Parting Tool Jigs: These specialized jigs help in sharpening the narrow, V-shaped edge of parting tools.

Abrasive Wheels: Grinders can be fitted with different types of grinding wheels. Aluminum oxide wheels are common for general grinding. For sharpening turning tools, especially with slow-speed grinders, diamond wheels are an excellent investment. They are durable, cut quickly, and are less prone to loading up with metal dust. A common setup is a coarse grit wheel for shaping and a finer grit wheel for honing, or using a CBN (Cubic Boron Nitride) wheel which is very efficient and long-lasting.

Pros:

- Versatile – can sharpen a wide range of tools.

- Relatively affordable to set up, especially if you already own a grinder.

- Jigs provide excellent control and consistency.

Cons:

- Requires learning to use the jigs correctly.

- Potential to overheat tools if using a high-speed grinder or not enough care.

- Takes up bench space.

2. Honing Machines and Strops

While grinders do the heavy lifting of establishing or reforming the cutting edge, honing machines and strops are essential for refining that edge to a razor-sharp finish. Honing removes microscopic burrs and aligns the very apex of the cutting edge, making it incredibly keen.

Honing Machines: These are often smaller, dedicated machines designed for finer abrasives, like diamond paste-coated wheels or very fine grit stones. They are used after grinding to achieve that final, polished cutting edge. Some systems use leather or felt honing wheels impregnated with abrasive compounds. They spin at relatively low speeds to avoid damaging the delicate edge you just created on the grinder.

Leather Strops: A leather strop, often mounted on a flat board or wheel, is a traditional and highly effective way to hone your tools. Coated with a fine abrasive compound (like chromium oxide or diamond paste), stropping realigns and polishes the edge. It’s a crucial final step for achieving a truly mirror-like, tooth-pick sharp edge that will slice through wood effortlessly.

Pros:

- Achieves the sharpest possible edge.

- Essential for the final finishing touch.

- Relatively simple to use once the tool is ground.

Cons:

- Cannot establish a primary bevel – primarily for refining.

- Requires abrasive compounds.

3. Specialized Electrical Sharpeners

There are also more integrated electrical sharpeners designed specifically for woodturning tools. These often combine a motor with a sharpening surface (like a diamond-coated wheel or a controlled abrasive belt) and sometimes built-in jigs or guides. They aim to provide a complete sharpening solution in one unit.

Examples include systems that use diamond-coated discs or belts at controlled speeds, often with articulating arms or platforms to hold the tool for consistent angles. Some are designed for specific tool types, while others are more general purpose.

Pros:

- All-in-one solutions can be very convenient.

- Often designed for specific tool types, offering good results.

- May offer precise angle control.

Cons:

- Can be more expensive than a grinder setup.

- Less versatile than a standard grinder with multiple attachments.

- If a component fails, the whole unit might be affected.

4. Manual Sharpening (Stones and Honing Guides)

While not a “machine” in the powered sense, manual sharpening on water stones or oil stones, combined with a good honing guide, is a time-honored method. For woodturning tools, this can be effective but often more time-consuming and challenging to achieve the consistent bevels required, especially for complex gouges. Honing guides are crucial here to hold the tool at a steady angle.

Pros:

- Quiet and dust-free.

- Can achieve very fine edges.

- Affordable entry point if you already have stones.

Cons:

- Can be slow and labor-intensive for turning tools.

- Achieving consistent bevels requires practice and skill.

- Less aggressive for repairing damaged edges compared to grinding.

Essential Tools and Accessories for Sharpening

Beyond the sharpening machine itself, several other items are vital for an effective and safe sharpening process. Think of these as your sharpening toolkit.

- Safety Glasses: Always wear safety glasses when grinding or sharpening. Sparks and metal particles can fly.

- Dust Mask: Grinding metal and wood dust can be harmful to inhale.

- Magnifying Glass: To inspect your edge for burrs, chips, and the quality of the honed surface.

- Angle Gauge or Bevel Gauge: To set up your jigs and verify that you are maintaining the correct bevel angles for your tools. Different tools require different angles for optimal performance (e.g., a bowl gouge needs a different angle than a skew chisel).

- Sharpening Compound: For use with strops or honing wheels. Common compounds include aluminum oxide, chromium oxide, and diamond paste in various grits.

- Tool Rests: Ensure your grinder has sturdy tool rests that can be adjusted to the correct height and angle for the jig or tool being sharpened.

- Bench Grinder Stand: If you don’t have a sturdy workbench, a dedicated stand provides stability.

Step-by-Step Guide: Sharpening a Bowl Gouge with a Grinder and Jig

Let’s walk through a common scenario: sharpening a bowl gouge using a slow-speed grinder and a typical bowl gouge jig. This is a fundamental skill for any woodturner.

Tools Needed:

- Slow-speed bench grinder (1700-1800 RPM)

- Bowl gouge sharpening jig

- Bowl gouge (e.g., 1/2 inch or 5/8 inch)

- Safety glasses

- Hearing protection (optional, but recommended)

- Dust mask

- Marker (e.g., Sharpie)

- Leather strop with honing compound

The Process:

- Preparation and Safety First:

- Ensure your grinder is securely mounted and the wheels are in good condition.

- Wear your safety glasses, dust mask, and any other recommended personal protective equipment (PPE).

- Adjust the tool rests on your grinder to be close to the grinding wheel—about 1/8 inch away—but with clearance for the jig to move.

- Mark the Gouge:

- Using a marker, draw a line along the bevel of your gouge. This line will visually disappear as you grind, indicating where you’ve removed metal and ensuring you don’t over-grind. You only need to grind enough to remove the dullness and re-establish the bevel without significantly changing the tool’s geometry.

- Set Up the Jig:

- Mount the bowl gouge jig according to its manufacturer’s instructions.

- Adjust the jig’s angle. For a typical bowl gouge used for general bowls, a bevel angle of around 30-40 degrees is common. Consult your jig’s manual or a reliable woodworking resource like Wood Magazine’s sharpening guides for specific recommendations.

- Ensure the jig is positioned so that when the gouge is held in it, the bevel makes contact with the grinding wheel at the desired angle. The flute of the gouge should be oriented correctly relative to the wheel.

- Grind the Bevel:

- Turn on the grinder.

- Place the gouge into the jig, ensuring it’s held securely.

- Bring the beveled edge of the gouge into contact with the spinning grinding wheel.

- Start with one side of the flute. Move the jig and tool smoothly across the grinding wheel in a figure-eight pattern or a controlled sweep. This ensures even metal removal and prevents ‘dishing’ of the wheel.

- Grind until the marker line you drew disappears from that side of the bevel.

- Remove the gouge from the jig.

- Flip the gouge and repeat the process on the other side of the flute, aiming for the same bevel angle. Grind until the marker line disappears on this side. You are aiming to create a consistent bevel that meets at the cutting edge.

- Periodically dip the gouge in water to cool it. Do NOT quench hot steel in water, as this can cause it to crack or warp. Just a quick dip to keep it from overheating. Overheating will ruin the temper.

- Check for a Burr:

- Turn off the grinder. Carefully pick up the gouge. Lightly rub your fingertip across the cutting edge (never along it). You should feel a tiny burr or wire edge on the opposite side of the bevel you just ground. This indicates you’ve ground all the way to the apex, creating a sharp point. If you don’t feel a burr, you need to grind a bit more.

- Hone the Edge:

- This is where you get that screaming sharp edge.

- Apply a small amount of sharpening compound to your leather strop or honing wheel.

- Present the bevel of the gouge to the strop/wheel at the sharpening angle (or slightly less).

- Move the gouge along the strop/wheel, maintaining the bevel angle. For a strop, move away from the edge. For a honing wheel, move into the edge (check your specific honing method instructions).

- Perform 5-10 passes on each side of the bevel.

- You can often strop the inner face of the gouge as well to remove any burr that might have formed there.

- Test the Edge:

- Carefully feel the edge. It should be incredibly sharp, almost effortless to cut. A well-sharpened bowl gouge should be able to shave thin wisps of paper or even slice through a stray thumbnail with the lightest of touches (be extremely careful when testing!).

- Final Check:

- Look at the edge under magnification if possible. It should be bright and shiny, with no visible nicks or dull spots.

Regularly touching up your tools on the strop is much easier and quicker than re-grinding every time. For a more in-depth understanding of bevel angles and tool geometry, resources from institutions like the Woodturners Guild of Ontario offer valuable insights.

Sharpening Other Wood Lathe Tools

The principles of grinding and honing apply to other wood lathe tools, but the specific jigs and angles will differ.

Skew Chisels

Skew chisels are used for fine finishing. They require a very keen, polished edge. When sharpening, you typically aim to maintain the long, sweeping bevel. Jigs are available to hold the skew at the correct angle, and care must be taken to avoid creating a ‘hook’ at the cutting edge which can lead to catches. The sharpening process involves presenting the bevel face to the grinder.

Scrapers

Scrapers (like round nose, square end, and thumbnail scrapers) are sharpened differently. They are not ground to a fine bevel in the same way as gouges. Instead, the edge is typically burnished to create a small ‘hook’ or burr at the cutting edge. This hook is what does the scraping. If a scraper gets nicked or the hook is lost, you can grind the face that forms the hook, and then re-burnish it. A flat grinding wheel attachment or a dedicated scraper sharpening jig can be helpful.

Parting Tools

These narrow tools have a unique shape. They are often sharpened by grinding at an angle to the sides of the cutting tip. Some specialized jigs exist for this, or they can be sharpened carefully by hand on a grinding wheel, ensuring the correct primary bevel is maintained and the side clearances are preserved.

Spindle Gouges

Similar to bowl gouges, spindle gouges are used for smaller, more detailed work. They generally have a more pointed profile and often require a steeper bevel angle for efficient cutting in end grain and fine shavings. The sharpening process with a jig is very similar to bowl gouge sharpening.

Maintaining Your Sharpening Machine and Tools

Just like your lathe tools, your sharpening machine needs care to perform at its best.

- Wheel Dressing: Grinding wheels can become loaded with metal dust, glaze over, or lose their shape. A grinding wheel dresser is used to clean, flatten, and sharpen the surface of the wheel, ensuring efficient and effective grinding.

- Wheel Balance: If your grinder wheels seem unbalanced, causing vibration, you may need to use a wheel balancing system.

- Lubrication: Ensure any moving parts on your grinder or jigs are kept clean and lightly lubricated according to the manufacturer’s recommendations.