Quick Summary: Find the sweet spot for 1/4 inch face mill feeds and speeds in cast iron! For cast iron, start with surface speeds around 200-300 SFM (Surface Feet per Minute) and adjust your RPM and chip load to achieve efficient, clean cuts. We’ll guide you through finding the perfect combination for your 1/4 inch face mill.

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Are you staring at a block of cast iron, a shiny new 1/4 inch face mill, and a bit of uncertainty about how fast you should make it spin and feed? You’re not alone! Getting that perfect balance of speed, feed, and depth of cut is key to smooth machining, tool longevity, and a great finish on your cast iron projects. Too fast, and you risk burning up your insert or cutter. Too slow, and you get rubbing, chatter, and a poor surface finish. It can feel like a puzzle when you’re just starting out. But don’t worry, we’re going to break it down into simple, actionable steps. Let’s dive in and unlock those genius cast iron speeds for your 1/4 inch face mill!

Understanding the Basics: SFM, RPM, and Chip Load

Before we get to the specific numbers, it’s important to understand three core concepts: Surface Feet per Minute (SFM), Revolutions Per Minute (RPM), and Chip Load. Think of them as the ingredients in our machining recipe.

- Surface Feet per Minute (SFM): This is the speed at which the cutting edge of your tool moves across the material’s surface. It’s measured in feet per minute. Different materials and tool types have recommended SFM ranges. Faster SFM generally means faster material removal, but it also generates more heat and wear.

- Revolutions Per Minute (RPM): This is how fast your spindle is rotating. It’s what you set on your machine. The SFM of your tool is directly related to your machine’s RPM and the diameter of your cutting tool.

- Chip Load: This is the thickness of the chip that each cutting edge of your tool removes with each revolution. It’s often expressed as “thousandths of an inch per tooth” (in/tooth). A good chip load is crucial for efficient cutting and preventing tool breakage. Too small, and you’re rubbing; too large, and you’re overloading the tool.

The relationship between these is a fundamental formula:

RPM = (SFM 12) / (π Tool Diameter)

And:

Feed Rate (IPM) = RPM Chip Load (in/tooth) Number of Flutes/Teeth

We’ll use these to guide our settings.

Why Cast Iron is Special (and a Bit Tricky)

Cast iron is a fantastic material for many parts, offering good strength, vibration damping, and machinability. However, compared to softer metals like aluminum, it has some characteristics that affect how we machine it:

- Abrasiveness: Cast iron can be quite abrasive, especially gray cast iron. This means it tends to wear down cutting tools faster than materials like mild steel or aluminum.

- Brittleness: While strong, cast iron can also be brittle. This means it doesn’t deform as much as ductile materials before fracturing. We need to manage chip loads to avoid chipping our inserts prematurely.

- Chip Formation: Cast iron chips tend to be short and brittle, which is generally good for chip evacuation but can also lead to abrasive dust.

- Heat: Machining cast iron generates heat. Managing this heat is important for tool life and surface finish.

Targeting Your 1/4 Inch Face Mill for Cast Iron

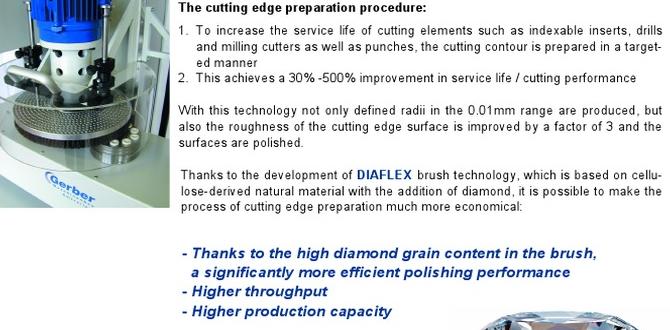

A 1/4 inch face mill is a common size for a variety of tasks, from surfacing small parts to light milling. When choosing one for cast iron, consider the insert material and geometry. For general cast iron machining, carbide inserts are usually the go-to. Sintered carbide inserts with a PVD (Physical Vapor Deposition) coating, often labeled for steels or universal applications, can perform well on cast iron. A general-purpose grade with a slightly rounded cutting edge (toecut) can help handle the abrasive nature of iron.

Recommended Starting Speeds and Feeds for a 1/4 Inch Face Mill on Cast Iron

Finding that “genius” speed isn’t about a single magic number, but a range and a process of refinement. For cutting cast iron with a 1/4 inch face mill, we’re typically looking at a surface speed (SFM) that’s a bit lower than what you might use for aluminum but higher than for some exotic exotic alloys. A good starting range for common carbide inserts in cast iron is often between 200 to 300 SFM.

Let’s create a table to illustrate potential starting points. Remember, these are starting points and will need adjustments based on your specific machine, insert grade, depth of cut, and coolant use.

| Parameter | Typical Range for 1/4″ Face Mill on Cast Iron | Important Considerations |

|---|---|---|

| Surface Speed (SFM) | 200 – 300 SFM | Start at the lower end if unsure, especially with older machines or less rigid setups. |

| Chip Load (in/tooth) | 0.002″ – 0.005″ | Smaller chip loads are safer for finishing or lighter cuts. Larger loads are for heavy roughing if your machine and tool can handle it. |

| Depth of Cut (DOC) | 0.050″ – 0.100″ (for finishing) 0.100″ – 0.250″ (for roughing, requires rigid machine) |

Always consider the radial depth of cut as well. For face milling, the radial engagement (how much of the cutter’s diameter is engaged in the cut) also impacts performance. |

| Coolant/Lubrication | Flood coolant or Mist recommended | Helps with chip evacuation, tool cooling, and chip welding prevention. Dry machining is possible but often leads to reduced tool life. |

Let’s take a specific example. Suppose you have a 1/4 inch face mill with 4 teeth (flutes) and you want to start with 250 SFM.

First, calculate the target RPM:

RPM = (250 SFM 12) / (3.14159 0.25 inches)

RPM ≈ (3000) / (0.7854)

RPM ≈ 3819

This means your machine should be set to around 3800 RPM. Now, let’s set a chip load. For a good general-purpose cut, let’s aim for 0.004 inches per tooth.

Next, calculate the feed rate in Inches Per Minute (IPM):

Feed Rate (IPM) = RPM Chip Load Number of Teeth

Feed Rate (IPM) = 3819 0.004 in/tooth 4 teeth

Feed Rate (IPM) ≈ 61.1

So, a starting point for your 1/4 inch face mill on cast iron might be 3800 RPM and a feed rate of approximately 60 IPM. With a depth of cut around 0.050 inches.

Factors Influencing Your “Genius” Speeds and Feeds

While the numbers above are great starting points, several factors can push you to go a little faster or slower, or adjust your feed:

Machine Rigidity and Power

A solid, rigid machine tool is paramount. If your machine has play in the ways, a weak spindle, or you’re experiencing vibration (chatter), you’ll need to reduce your feed rate and possibly your depth of cut. A powerful motor will also allow you to maintain your target RPM even under load. Smaller hobby mills might require a more conservative approach than a heavy-duty industrial machine. For more on machine considerations, resources like NIST’s advanced machining research can offer context on the importance of machine capabilities.

Insert Geometry and Grade

Not all inserts are created equal. Look for inserts specifically designed or recommended for cast iron. They often have geometry that promotes good chip breaking and a coating or grade that resists abrasion. If your inserts are designed for high-speed machining of softer materials, you might need to lower your SFM. Conversely, a sharp, high-performance insert might handle slightly higher speeds.

Depth of Cut (DOC) and Radial Engagement

We talked about axial depth of cut (how deep the cutter goes into the material from the top). But radial engagement (how much of the cutter’s circumference is actually cutting at any one time) is also critical, especially with face mills. For a 1/4 inch face mill on a larger surface, you might only be engaging a small portion radially. This can lead to the tool “rubbing” rather than cutting cleanly. When this happens, you might need to increase your feed rate to ensure a proper chip is formed, or take shallower passes with more radial overlap.

Coolant and Lubrication

Using a suitable coolant or cutting fluid can significantly improve performance. It helps to:

- Cool the cutting edge, reducing wear and heat buildup.

- Lubricate the interface between the tool and the workpiece, reducing friction.

- Assist in flushing chips away from the cutting zone, preventing re-cutting and chip welding.

- For cast iron, a flood coolant system is often preferred for its cooling and chip-flushing abilities. Mist coolant can also work well, providing localized cooling and lubrication. Dry machining is possible, but it generally leads to hotter tools and more wear.

Step-by-Step: Finding Your Ideal Settings

Here’s a practical approach to dial in your speeds and feeds:

- Identify Your Tooling: Know your 1/4 inch face mill type, the number of teeth/flutes, and the insert grade you’re using.

- Start Conservatively: Using the table above, select a speed and feedrate from the lower end of the recommended range. For example, use 200 SFM and a chip load of 0.003 in/tooth.

- Calculate RPM and Feed Rate: Use the formulas to get your target RPM and the calculated IPM.

- Set Depth of Cut: Start with a moderate depth of cut, perhaps 0.050 inches for a finishing pass or 0.100 inches for a general-purpose cut.

- Engage the Material: For face milling, ensure you have sufficient radial engagement. If machining a surface smaller than the mill diameter, you’ll achieve this. For larger surfaces, the mill will naturally engage across its width.

- Make a Test Cut: Engage the material at your calculated feed rate and your chosen RPM.

- Listen and Observe:

- Sound: Listen for a consistent, sharp “shaving” sound. A harsh scraping or chattering indicates issues with rigidity, speed, or feed.

- Chips: Look at the chips being produced. They should be relatively small, broken, and have a consistent color (not blue from overheating).

- Surface Finish: Inspect the surface. Is it smooth with no scoring or tearing?

- Tool Condition: After the cut, examine the inserts for excessive wear, chipping, or signs of heat buildup.

- Adjust Incrementally:

- If the cut sounds dull, chips are large and stringy, or heat is building, the feed rate might be too low for the chip load, or the RPM might be too high. Try increasing the feed rate slightly (e.g., 10-15% in RPM first, or adjust IPM directly if possible) or decreasing RPM.

- If you hear chatter or the tool is chipping, reduce the feed rate or depth of cut. Your RPM might also be too high, leading to excessive heat.

- If the surface finish is poor or inserts are showing rapid wear, experiment with slightly higher SFM (increase RPM or lower motor load) to get a cleaner cut, but watch for heat.

- Optimize: Once you’re happy with the sound, chip formation, and surface finish, you’ve found your “genius” settings for that specific operation and material.

Common Pitfalls and How to Avoid Them

Even with great starting points, beginner machinists can run into trouble. Here are common issues and how to deal with them:

Excessive Chatter/Vibration

Chatter is the enemy of good finishes and tool life. It’s usually caused by a lack of rigidity somewhere in the system. This could be:

- Workpiece not clamped securely.

- Tool holder not seated properly.

- Machine spindle or ways are worn.

- Feed rate is too slow, causing the tool to dwell and “dig in.”

- Depth of cut is too aggressive for the setup.

Solution: Increase feed rate (to get a consistent chip), reduce depth of cut, ensure all setups are rigid, or try a different cutting strategy (e.g., climb milling vs. conventional milling, though climb milling is often preferred for cast iron with modern tooling).

Tool Wear / Insert Chipping

If your inserts are dulling or breaking quickly, you’re likely running too fast, feeding too slowly, or not using coolant effectively. Abrasive cast iron demands sharp tools and proper chip formation. For more information on tool wear types, resources from institutions like Sandvik Coromant can be invaluable for understanding the science behind tool life.

Solution: Reduce SFM (lower RPM), increase chip load (ensure you’re getting a proper chip, not rubbing), ensure adequate coolant flow, or try a tougher insert grade.

Poor Surface Finish / Burning

A rough or burnt surface indicates rubbing, insufficient cutting action, or excessive heat that’s welding chips to the tool or surface. This is a classic sign of running too slow a feed rate (for the RPM and chip load) or insufficient depth of cut, leading to rubbing and heat. It can also happen if the machine has backlash in the axes, causing the tool to oscillate.

Solution: Increase the feed rate (IPM) to ensure a proper chip is being formed, ensure adequate depth of cut and radial engagement, or consider using a different insert with a sharper cutting edge geometry if your current one has excessive land wear.

When to Use Climb Milling vs. Conventional Milling

When face milling, the direction your tool engages the material matters. Your mill will likely have a default direction (often conventional milling). However, for cast iron, climb milling often offers benefits:

- Conventional Milling: The cutter teeth move against the direction of feed. This tends to create more friction and heat, and can sometimes lift the material slightly.

- Climb Milling: The cutter teeth move in the same direction as the feed. This can result in a cleaner cut, less heat, and better chip evacuation. The cutting force pulls the workpiece into the cutter.

Important Note for Climb Milling: Climb milling requires a backlash-free or very tightly controlled axis drive. If your machine has significant backlash, climb milling can cause rapid tool breakage as the cutter “jumps” over the backlash. Many modern CNC machines are set up for climb milling by default. For manual machines, you need to be more cautious or ensure controls are adjusted.

For cast iron, if your machine setup is rigid and has minimal backlash, trying climb milling can often lead to improved surface finish and tool life.

Frequently Asked Questions (FAQs)

Q1: What is the best SFM for a 1/4 inch face mill in cast iron?

A: A good starting range for SFM is 200-300 SFM for carbide inserts. Always begin on the lower end and adjust based on your machine and tooling performance.

Q2: How do I calculate the right RPM for my face mill?

A: Use the formula: RPM = (SFM 12) / (π Tool Diameter). For a 1/4 inch (0.25″) tool at 250 SFM, it