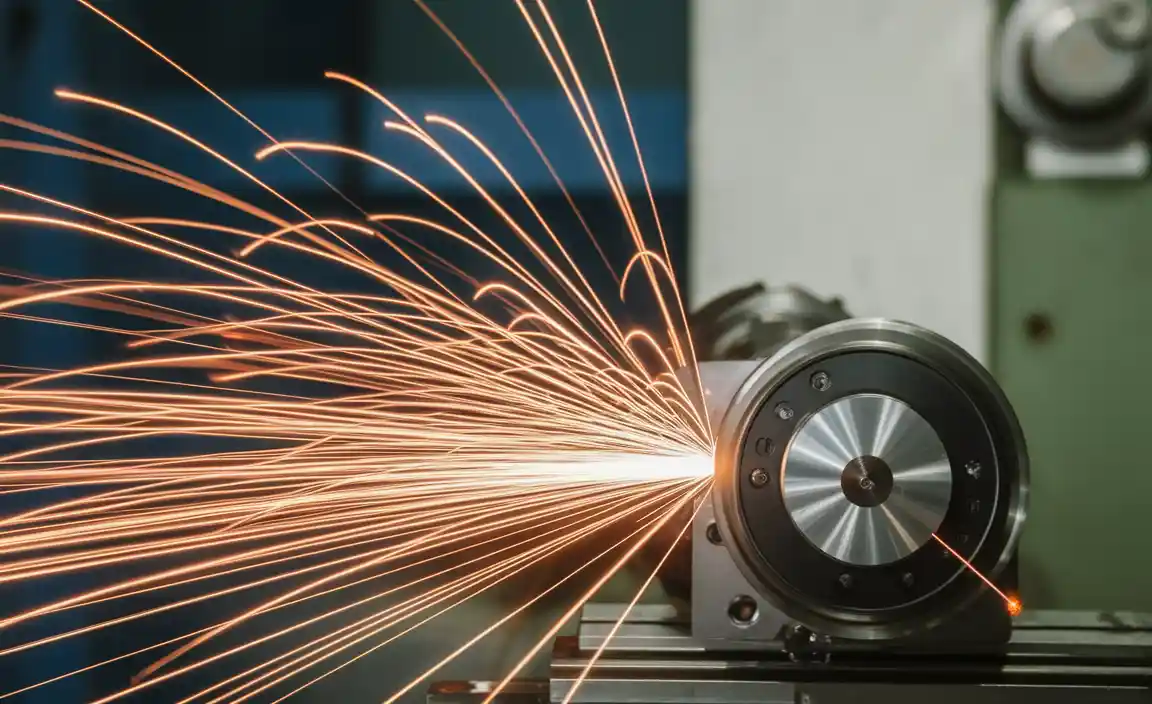

Have you ever watched a metal lathe in action? It’s fascinating! The whirring sound of gears and the smooth cutting of metal can captivate anyone. As we look forward to 2025, one key component makes these machines even better: the metal lathe belt.

Imagine your favorite toy. Now, think about how it works. Each part plays a role, just like a metal lathe belt. This simple piece helps the lathe spin and cut with precision. Without a strong, reliable belt, the machine can’t perform well.

Did you know that there are many kinds of metal lathe belts? Each type is designed for different tasks. Some belts are tough for big jobs, while others are flexible for tricky ones. Why is that important? Choosing the right belt can make your projects easier and more fun!

As we dive deeper into the world of 2025 metal lathe belts, you’ll discover secrets that can help hobbyists and professionals alike. Ready to learn more about this essential tool? Let’s explore!

2025 Metal Lathe Belt: Essential Guide For Your Workshop

Discover the benefits of the 2025 metal lathe belt for your workshop. This belt improves speed and efficiency, making your projects smoother. Did you know that a worn belt can slow down your production? Upgrading to a sturdy 2025 model ensures better performance and longevity. Plus, it’s easy to install! If you’re ready to boost your lathe’s performance, consider this essential upgrade. Your work will shine, and you’ll finish tasks quicker than ever!

Understanding Metal Lathe Belts

Definition and purpose of metal lathe belts. Types of belts used in metal lathes. Metal lathe belts are crucial parts of lathe machines. They help transfer power from the motor to the lathe, making it work smoothly. There are different types of belts used in lathes, including:

- V-belts – These are shaped like a V and grip pulleys well.

- Flat belts – These are flat and can handle high speeds.

- Timing belts – These stay in sync and prevent slippage.

Choosing the correct belt is important for the lathe’s performance. A good belt helps the machine run better and last longer.

What is the purpose of a metal lathe belt?

The purpose of a metal lathe belt is to connect the motor to the lathe spindle. This allows the lathe to turn and shape materials. Without a belt, the machine would not work.

Importance of Choosing the Right Belt for Your Metal Lathe

Impact on performance and machinery efficiency. Consequences of using the wrong belt. Choosing the right belt for your metal lathe is key to smooth operation. A good belt helps tools run well. It makes machines work more efficiently. If you pick the wrong belt, it can cause problems. You may notice:

- Poor performance: Your lathe may work slowly or not at all.

- Wear and tear: The wrong belt can wear out faster.

- Damage: It might hurt your machinery in the long run.

In short, the right belt boosts performance and saves costs.

What happens if you use the wrong belt?

Using the wrong belt can lead to serious damage.

Features to Look for in a 2025 Metal Lathe Belt

Material composition and durability. Size and compatibility with various lathe models.

Choosing the right metal lathe belt can make a big difference in your work. Start by considering the material composition. Look for belts made from strong materials like rubber or polyurethane which last longer. Next, check the size and compatibility. Not all belts fit every lathe. Make sure the belt matches your lathe model for smooth operation. Here are some key features:

- Durability: Strong materials resist wear.

- Size: Correct length and width are essential.

- Compatibility: Fits various lathe models.

How to Properly Install a 2025 Metal Lathe Belt

Step-by-step installation guide. Tools and safety precautions needed. Installing a 2025 metal lathe belt can be simple and fun! First, gather your tools: a wrench, screwdriver, and gloves for safety. Always wear goggles because nobody needs a surprise eye visit! Now, follow these steps:

| Step | Description |

|---|---|

| 1 | Turn off and unplug the lathe. |

| 2 | Remove the old belt carefully. |

| 3 | Place the new belt around the pulleys. |

| 4 | Tighten it and check for any snags. |

| 5 | Plug in the lathe and test it out! |

Remember, safety first! Tie back long hair and keep loose clothing away from the machine. Happy lathe-ing!

Maintenance Tips for Longevity of Metal Lathe Belts

Regular checks and common issues to watch for. Recommended cleaning and care practices. To keep your metal lathe belt in tip-top shape, regular checks are key. Look for wear and tear like cracks or frays. Instead of ignoring squeaks or slips, treat them like your annoying little brother—address them quickly!

For cleaning, a soft cloth does wonders. Avoid strong chemicals; they can cause more harm than a misbehaving cat. Remember, a well-maintained belt lasts longer and works better, giving you smooth turns and happy projects!

| Common Issues | Recommended Actions |

|---|---|

| Cracks or fraying | Replace immediately |

| Squeaking noises | Check alignment |

| Slipping | Adjust tension |

Cost Comparison: Budget vs. Premium 2025 Metal Lathe Belts

Analysis of price range and value. Pros and cons of budgetfriendly options vs. highend models.

Price matters when choosing a 2025 metal lathe belt. Budget options might save you money now, but are they worth it? Let’s compare:

- Budget Belts: Typically cost less. However, they may wear out quickly.

- Premium Belts: Often last longer and perform better. The cost is higher, but they offer value.

Think about your needs. Do you want to save money, or are you looking for long-lasting quality? Remember, a better belt can save you time and frustration later.

What are the benefits of budget vs. premium belts?

Budget belts are affordable but may not last long. Premium belts cost more but provide better quality and durability.

Customer Reviews and Testimonials

Insights from users of different brands. Common praises and complaints about specific belts.

Users share their experiences on the 2025 metal lathe belt. Many praise its durability and smooth operation. Complaints often focus on difficulty in installation. Here are some insights:

- Durable Materials: Most users love how long the belts last.

- Smooth Performance: Many feel the belts help machines run better.

- Tricky Setup: Some find it hard to install the belts properly.

Overall, feedback shows a strong preference for performance but highlights areas for improvement.

What do users think about this belt?

Users feel the 2025 metal lathe belt is great for its smooth operation and long life, but some struggle with installation.

Where to Buy 2025 Metal Lathe Belts

Recommended online retailers and marketplaces. Local suppliers and specialty stores. Searching for a 2025 metal lathe belt? You’re in luck! You can find them easily online. Retail giants like Amazon and eBay have a wide selection.

Don’t forget to check local stores, too. Specialty shops often carry unique options. A well-known store can offer expert advice and sometimes even a laugh or two. Check out the table below for a quick comparison of sources!

| Retailer | Type | Notes |

|---|---|---|

| Amazon | Online | Fast shipping! |

| eBay | Online | Unique finds! |

| Local Hardware Store | Local | Expert advice! |

| Specialty Shops | Local | High quality! |

Conclusion

In conclusion, the 2025 metal lathe belt is crucial for smooth operation and precision. It’s important to choose the right size and material. Regular maintenance will keep your lathe running well. We encourage you to explore more about lathe belts and how to install them. Taking these steps will make your metalworking projects even better!

FAQs

What Specifications Should I Consider When Selecting A Replacement Belt For A 20Metal Lathe?

When choosing a replacement belt for a 20-inch metal lathe, look at a few things. First, check the belt size and length. You need to make sure it fits your lathe perfectly. Next, consider the belt material; rubber or neoprene is often strong. Finally, think about the belt’s strength; it should handle the weight and use of your lathe well.

How Can I Determine If The Belt On My 20Metal Lathe Needs To Be Replaced?

To see if the belt on your lathe needs replacing, first check for cracks or wear. If the belt feels loose, it may need a change. Listen for any strange noises when the lathe runs, like squeaking. If it doesn’t spin properly, that’s another sign it’s time to replace the belt. Always make sure the machine is off before you look at it!

What Are The Best Practices For Maintaining The Belt Of A 20Metal Lathe To Ensure Longevity And Optimal Performance?

To keep the belt of your metal lathe in great shape, check it often. You should look for any signs of wear or fraying. Make sure the belt is adjusted properly so it isn’t too loose or tight. Clean the belt and the pulleys regularly to prevent dust buildup. Lastly, if the belt gets damaged, replace it right away to keep your lathe running well.

Are There Any Specific Brands Or Manufacturers Recommended For Belts Compatible With A 20Metal Lathe?

You can look for belts from brands like Gates, Dayco, or Browning. These companies make good belts that fit many lathes. Make sure to check the size you need for your 20-inch metal lathe. You can also ask at your local hardware store for help. They can guide you to the right belts!

What Are The Common Issues Caused By A Worn Or Faulty Belt In A 20Metal Lathe, And How Can I Troubleshoot Them?

A worn or faulty belt on a 20 metal lathe can cause problems like slipping, strange noises, or the machine not working. If the belt slips, it might not turn the parts properly. If you hear strange noises, the belt might be loose or damaged. You can troubleshoot by checking the belt for wear or tears. If it’s damaged, you should replace it or tighten it to fix the problems.

Resource:

-

Belt drive system basics

URL: https://www.explainthatstuff.com/howbeltdriveswork.html

→ Explains how belt drives function and their importance in machines -

Anchor Text: Choosing rubber vs. polyurethane belts

URL: https://www.machinedesign.com/mechanical-motion-systems/article/21832462/understanding-belts-and-belting

→ Insightful guide on belt materials and industrial use -

Anchor Text: Machine safety during maintenance

URL: https://www.osha.gov/machine-guarding

→ Provides safety tips when changing belts on lathes or machines -

Anchor Text: Preventive maintenance for workshop tools

URL: https://www.woodmagazine.com/tool-reviews/maintenance/keep-your-tools-in-top-shape

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A 20Metal Lathe Belt:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A 20 metal lathe belt is a part that helps the machine work. It connects the motor to the lathe, which shapes metal. If the belt breaks, the lathe won’t spin. You need to check it regularly to keep everything running smoothly. Always be careful when working with machines!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Specifications Should I Consider When Selecting A Replacement Belt For A 20Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a replacement belt for a 20-inch metal lathe, look at a few things. First, check the belt size and length. You need to make sure it fits your lathe perfectly. Next, consider the belt material; rubber or neoprene is often strong. Finally, think about the belt’s strength; it should handle the weight and use of your lathe well.”}},{“@type”: “Question”,”name”: “How Can I Determine If The Belt On My 20Metal Lathe Needs To Be Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if the belt on your lathe needs replacing, first check for cracks or wear. If the belt feels loose, it may need a change. Listen for any strange noises when the lathe runs, like squeaking. If it doesn’t spin properly, that’s another sign it’s time to replace the belt. Always make sure the machine is off before you look at it!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining The Belt Of A 20Metal Lathe To Ensure Longevity And Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the belt of your metal lathe in great shape, check it often. You should look for any signs of wear or fraying. Make sure the belt is adjusted properly so it isn’t too loose or tight. Clean the belt and the pulleys regularly to prevent dust buildup. Lastly, if the belt gets damaged, replace it right away to keep your lathe running well.”}},{“@type”: “Question”,”name”: “Are There Any Specific Brands Or Manufacturers Recommended For Belts Compatible With A 20Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can look for belts from brands like Gates, Dayco, or Browning. These companies make good belts that fit many lathes. Make sure to check the size you need for your 20-inch metal lathe. You can also ask at your local hardware store for help. They can guide you to the right belts!”}},{“@type”: “Question”,”name”: “What Are The Common Issues Caused By A Worn Or Faulty Belt In A 20Metal Lathe, And How Can I Troubleshoot Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A worn or faulty belt on a 20 metal lathe can cause problems like slipping, strange noises, or the machine not working. If the belt slips, it might not turn the parts properly. If you hear strange noises, the belt might be loose or damaged. You can troubleshoot by checking the belt for wear or tears. If it’s damaged, you should replace it or tighten it to fix the problems.”}}]}