Have you ever watched someone use a metal lathe? It can be both exciting and a little scary. These machines spin metal to create amazing shapes. However, safety is key. In 2025, metal lathe safety is more important than ever. Each year, accidents happen because people don’t follow safe practices.

Imagine working on a project and losing focus for just a moment. That can be enough for an accident to occur. Did you know that many safety issues come from simple mistakes? Learning the right safety tips can help you stay safe while you work on your lathe.

In this article, we will explore essential safety guidelines for using a metal lathe in 2025. You will discover how to protect yourself and others. Let’s dive in and make every turning project a safe and fun adventure!

2025 Metal Lathe Safety: Essential Tips For Safe Operation

2025 Metal Lathe Safety

Staying safe while using a metal lathe is crucial, especially in 2025. Proper training is key. Always wear safety glasses and keep long hair tied back. You may be surprised to know that most accidents happen because of distractions. Have you ever seen someone ignore safety gear? It’s a risky move! For a safe workspace, keep it clean and organized. Remember, safety first means smooth turning later!Essential Personal Protective Equipment (PPE)

List of necessary PPE for lathe operation. How to properly use and maintain PPE.Using the right personal protective equipment (PPE) is essential for staying safe while working with a lathe. Key items that everyone should wear include:

- Safety goggles: Protect your eyes from flying metal chips.

- Hearing protection: Reduce noise from the machine.

- Gloves: Wear them if they fit well, but be careful not to get them caught.

- Steel-toed boots: Shield your feet from heavy equipment.

- Dust masks: Keep dust and particles out of your lungs.

To use PPE properly, make sure it fits well and is in good condition. Clean your gear regularly to keep it effective and safe. Check for any damage before use. Remember, PPE is your first line of defense against injuries!

Why is PPE important?

Using PPE protects you from serious injuries. It makes a big difference in your safety while working with machines like lathes.

How often should you check your PPE?

Always check your PPE before starting work. Change damaged items immediately. Regular maintenance keeps you safe.

Pre-Operational Safety Checks

Checklist for inspecting the lathe before use. Importance of ensuring all safety features are functioning.Before using a lathe, it’s important to check it carefully. This helps keep you safe and ensures the machine works well. Here’s a simple checklist:

- Inspect the power supply.

- Check for loose parts.

- Ensure safety guards are in place.

- Test the emergency stop button.

- Look for damaged wires.

Making sure all safety features work is a must. This way, you prevent accidents and stay safe while working. Remember, safety first means more fun while you create!

Why are preoperational safety checks important?

Preoperational safety checks help prevent accidents and injuries. Ensuring everything works can save you from serious problems when using the lathe.

Safe Operating Procedures

Stepbystep guide on safe lathe operation. Importance of maintaining focus and avoiding distractions.To safely operate a metal lathe, follow these steps:

- Always wear protective gear like goggles and gloves.

- Check tools and machine for any damage.

- Keep your workspace clean and organized.

- Stay focused and avoid distractions, such as phone use.

- Use the right speed and feed settings for your material.

Maintaining focus is crucial. Even a moment of distraction can lead to serious accidents. Remember, safety first!

Why is focus important while using a lathe?

Focus helps prevent accidents and injuries. A single lapse can cause serious mistakes.

Statistics show that many accidents happen due to distractions. Always pay attention to your work. It’s not just a machine; it’s a tool that needs respect!

Emergency Procedures and First Aid

What to do in case of an accident. Basic first aid measures for common lathe injuries.Accidents happen, even in the workshop. If you or someone else gets hurt while using a lathe, stay calm. First, turn off the machine. Next, check the injury. For cuts, apply pressure to stop the bleeding. If it’s serious, seek professional help. Basic first aid can prevent things from getting worse. Here’s a handy table for quick reference:

| Injury | Action |

|---|---|

| Cut | Apply pressure, clean, bandage |

| Burn | Cool with water, cover with a clean cloth |

| Shock | Lay down, keep warm, call for help |

Remember, safety first! With a little preparation, you can turn a mishap into a learning moment. After all, who knew first aid could be another skill to show off?

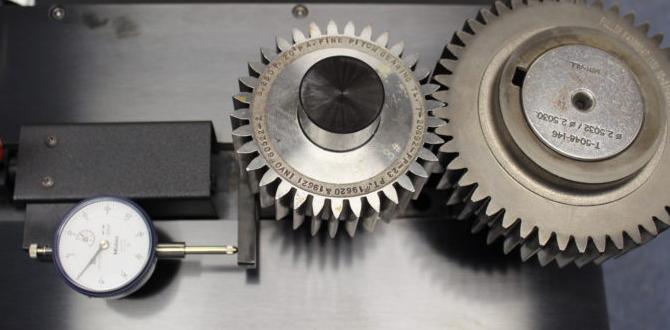

Regular Maintenance for Safety

Importance of routine maintenance and inspections. Key components of a maintenance schedule.Keeping your metal lathe in tip-top shape is key to staying safe. Regular check-ups help catch problems before they get out of hand. Imagine finding out your lathe has a wobbly part right before you start a big project—yikes! A good maintenance schedule should include checking the machine’s belt tension, lubrication, and safety guards.

| Maintenance Task | Frequency |

|---|---|

| Check Lubrication | Weekly |

| Tighten Belts | Monthly |

| Inspect Safety Guards | Every Use |

Taking care of these parts can make a big difference. After all, a happy lathe is a safe lathe, and your fingers will thank you!

Training and Skill Development

Importance of formal training for safe operation. Resources for ongoing education and skill enhancement.Learning how to operate a metal lathe safely is super important! Formal training teaches you the proper techniques to keep fingers and toes away from dangerous spots. You wouldn’t want to play tag with a spinning machine, would you? There are many resources for ongoing education, like workshops and online courses. These help sharpen your skills and keep you updated on new safety standards. After all, a skilled operator is a safe operator!

| Resource Type | Description |

|---|---|

| Workshops | Hands-on experience with expert guidance. |

| Online Courses | Learn at your own pace with videos and quizzes. |

| Safety Manuals | Detailed guidelines for safe operations. |

Remember, knowledge is power! With the right training, you’ll turn into a metal lathe wizard in no time.

Innovations in Metal Lathe Safety for 2025

Upcoming technologies and features in metal lathes. How these innovations can improve worker safety.New tools and features are changing how we use metal lathes. These innovations focus on making work safer for everyone. For example, many machines will have:

- Automatic shut-off systems

- Better guards and shields

- Smart sensors to detect problems early

These updates can reduce accidents and keep workers safe. With smart technology, workers can focus better. They can feel more secure while using machines. It’s all about making metal lathe safety better in 2025!

What are some benefits of new metal lathe safety features?

New safety features can dramatically lower workplace injuries. Workers feel more secure and confident using machines with these advancements. Less worry means a smoother working environment!

Common Myths about Metal Lathe Safety

Debunking misconceptions related to lathe operation. The impact of misinformation on workplace safety standards.Many people believe incorrect ideas about metal lathe safety. These myths can make work dangerous. For example, some think that if you wear goggles, you’re safe. This isn’t true because there are other risks. Misinformation leads to unsafe habits, which can cause accidents. It’s essential to clear up these myths to keep everyone safe. Here are a few common misconceptions:

- Wearing gloves is always safe while operating.

- Young workers can’t learn lathe safety.

- Metal lathes are only safe for experienced users.

What are some common myths about metal lathe safety?

Myths include thinking that protective gear alone makes you safe. Proper training and knowledge are key. Everyone must learn the correct safety practices to avoid harm.

Conclusion

In 2025, metal lathe safety is crucial for everyone in the workshop. Always wear protective gear and stay focused. Understand your machine’s features and follow all safety guidelines. Regularly check for any issues and keep your work area tidy. By practicing these tips, you can create a safer environment. We encourage you to learn more about metal lathe safety to protect yourself!FAQs

Sure! Here Are Five Questions Related To The Topic Of 20Metal Lathe Safety:Sure! Here are some answers to questions about metal lathe safety: 1. Always wear safety goggles. They protect your eyes from flying pieces. 2. Keep hair tied back and wear snug clothing. Loose clothing can get caught in the machine. 3. Make sure your hands are clear when the lathe is running. This helps prevent injuries. 4. Always use the right tools and follow instructions. This keeps you safe while using the lathe. 5. If you feel tired or distracted, take a break. It’s important to stay focused while working.

Sure! Please ask your question, and I’ll be happy to help.

What Are The Updated Safety Standards And Regulations For Operating Metal Lathes In 2025?In 2025, we have new safety standards for using metal lathes. You must always wear protective gear, like goggles and gloves. Keep the work area clean to avoid accidents. Always check the machine before you use it. Make sure everyone knows the safety rules to stay safe while working.

What Personal Protective Equipment (Ppe) Is Recommended For Workers Operating Metal Lathes To Ensure Safety?When you use a metal lathe, you should wear safety goggles to protect your eyes from flying pieces. A face mask can help keep dust out of your lungs. You should wear gloves to protect your hands. Steel-toed shoes are important to protect your feet. Finally, a lab coat or apron keeps your clothes safe and clean.

How Can Manufacturers Improve The Design Of Metal Lathes To Enhance Operator Safety And Reduce The Risk Of Accidents?Manufacturers can make metal lathes safer by adding protective covers. These covers keep your hands away from moving parts. They can also place emergency buttons within easy reach. Better lighting helps you see what you’re doing. Finally, clear instructions can help everyone use the lathe safely.

What Training Programs Are Available For New Operators To Ensure They Understand Metal Lathe Safety Protocols In 2025?In 2025, there are many training programs for new metal lathe operators. You can take online courses to learn safety rules. Some schools offer hands-on classes to practice using the lathe safely. We can also watch videos that show safe ways to work. It’s important to know these safety steps to keep everyone safe while using the machine.

How Should An Operator Respond In The Event Of A Malfunction Or Emergency While Using A Metal Lathe?If you notice a problem with the metal lathe, stop the machine right away. Unplug it to make sure it’s safe. Check to see what’s wrong. If you can’t fix it, ask for help from a grown-up. Always stay calm and follow safety rules.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of 20Metal Lathe Safety:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers to questions about metal lathe safety: 1. Always wear safety goggles. They protect your eyes from flying pieces. 2. Keep hair tied back and wear snug clothing. Loose clothing can get caught in the machine. 3. Make sure your hands are clear when the lathe is running. This helps prevent injuries. 4. Always use the right tools and follow instructions. This keeps you safe while using the lathe. 5. If you feel tired or distracted, take a break. It’s important to stay focused while working.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Updated Safety Standards And Regulations For Operating Metal Lathes In 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In 2025, we have new safety standards for using metal lathes. You must always wear protective gear, like goggles and gloves. Keep the work area clean to avoid accidents. Always check the machine before you use it. Make sure everyone knows the safety rules to stay safe while working.”}},{“@type”: “Question”,”name”: “What Personal Protective Equipment (Ppe) Is Recommended For Workers Operating Metal Lathes To Ensure Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, you should wear safety goggles to protect your eyes from flying pieces. A face mask can help keep dust out of your lungs. You should wear gloves to protect your hands. Steel-toed shoes are important to protect your feet. Finally, a lab coat or apron keeps your clothes safe and clean.”}},{“@type”: “Question”,”name”: “How Can Manufacturers Improve The Design Of Metal Lathes To Enhance Operator Safety And Reduce The Risk Of Accidents?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manufacturers can make metal lathes safer by adding protective covers. These covers keep your hands away from moving parts. They can also place emergency buttons within easy reach. Better lighting helps you see what you’re doing. Finally, clear instructions can help everyone use the lathe safely.”}},{“@type”: “Question”,”name”: “What Training Programs Are Available For New Operators To Ensure They Understand Metal Lathe Safety Protocols In 2025?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In 2025, there are many training programs for new metal lathe operators. You can take online courses to learn safety rules. Some schools offer hands-on classes to practice using the lathe safely. We can also watch videos that show safe ways to work. It’s important to know these safety steps to keep everyone safe while using the machine.”}},{“@type”: “Question”,”name”: “How Should An Operator Respond In The Event Of A Malfunction Or Emergency While Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you notice a problem with the metal lathe, stop the machine right away. Unplug it to make sure it’s safe. Check to see what’s wrong. If you can’t fix it, ask for help from a grown-up. Always stay calm and follow safety rules.”}}]}