Are you thinking about setting up a metal lathe in 2025? You might wonder what it takes to create the perfect workspace. Picture this: a place where you craft amazing projects with precision and ease. Sounds exciting, right?

Metal lathes are important tools for makers, hobbyists, and professionals alike. They shape and cut metal into amazing designs. But how do you get started with a metal lathe setup? It might seem tricky, but it’s easier than you think!

In this article, we will explore the details of setting up your metal lathe for 2025. You’ll learn what tools you need and how to arrange your space. Did you know that a well-set lathe can help you finish projects faster? This setup can make a big difference in your work!

Let’s dive into the world of metal lathes and discover how to make your setup simple and effective. Get ready to turn your ideas into reality!

2025 Metal Lathe Setup: Essential Tips For Optimal Performance

Setting up a metal lathe in 2025 can be exciting! A metal lathe helps shape metal into parts for machines and tools. You’ll learn about selecting the right lathe, essential tools to have, and tips for safety. Did you know that a well-set-up lathe can save you time? It’s important to measure twice, cut once. Proper setup not only improves accuracy but also boosts your skills. Start your journey in metalworking with confidence!

Understanding Metal Lathes

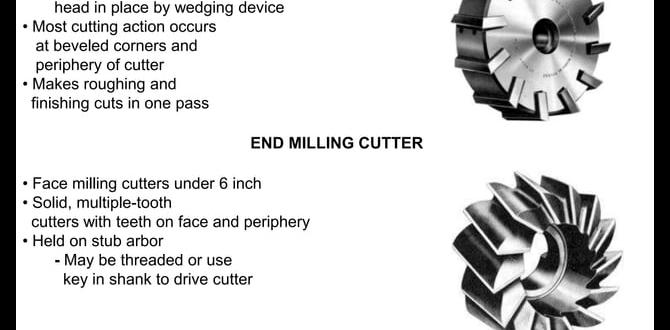

Definition and functionality of a metal lathe. Types of metal lathes and their applications.

A metal lathe is a machine that shapes metal into cylinders. Think of it like a giant pencil sharpener, but for your projects. They spin metal pieces while cutting tools shape them. Metal lathes come in various types, each serving a unique purpose. Some are small for hobbyists, while others are huge for factories. Check out the table below for a quick overview of common types and their uses:

| Type of Metal Lathe | Application |

|---|---|

| Bench Lathe | Small projects, home workshops |

| CNC Lathe | Automated, precision tasks |

| Engine Lathe | General machining tasks |

Each lathe has a special job, making sure no project is left behind. Who knew shaping metal could be so fun?

Choosing the Right Metal Lathe for 2025

Key features to consider when selecting a metal lathe. Comparison of popular metal lathe models available in 2025. Picking the right metal lathe can feel like choosing a pet—each one has its quirks! First, think about size and capacity.

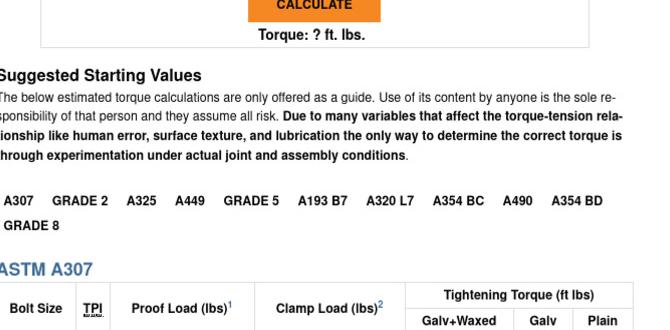

Will it fit in your garage? Next, look for features like a digital readout or variable speed settings. These make work easier! In 2025, popular models include the XYZ-1000 and the ABC-500. Each one has strengths, like power or precision. Check out the table below to compare!

| Model | Power (HP) | Speed Range (RPM) | Price |

|---|---|---|---|

| XYZ-1000 | 1.5 | 0-2000 | $1,200 |

| ABC-500 | 2.0 | 0-3000 | $1,500 |

Essential Tools and Accessories for Metal Lathe Setup

List of musthave tools for a complete metal lathe setup. Optional accessories that enhance lathe performance.

Setting up a metal lathe requires the right tools. Here are some must-have items:

- Cutting tools

- Tool holders

- Chucks

- Tailstocks

- Measuring tools

Optional accessories can improve your lathe’s performance. Consider adding:

- Quill drive systems

- Part catchers

- Wrenches and screwdrivers

These items will help you work more safely and effectively.

What are the key tools for a metal lathe setup?

Key tools include cutting tools, tool holders, chucks, tailstocks, and measuring instruments.

Step-by-Step Guide to Setting Up Your Metal Lathe

Preparing your workspace: layout and safety considerations. Assembly tips for ensuring proper setup and alignment. Before setting up your metal lathe, you need a clean and safe workspace. Keep tools tidy and clear away clutter. Choose a spot with good lighting. It’s also smart to have safety gear nearby, like gloves and goggles. Consider these tips for your setup:

- Keep lathe parts together

- Use a level surface for proper alignment

- Check warnings in the user manual

- Secure all connections tightly

Making sure everything aligns well is key for success. Follow these steps for a smoother setup process!

What materials do I need to set up a metal lathe?

The essential materials include tools, safety gear, and a manual. Having everything ready helps avoid problems and saves time.

Start by laying out the parts. Be mindful of safety while you work. A well-prepared workspace leads to better projects!

Safety Precautions When Using a Metal Lathe

Essential safety gear and practices to follow. Common hazards and how to mitigate them.

Using a metal lathe can be fun, but safety comes first. Always wear safety goggles to protect your eyes. Use ear protection to keep your hearing safe from loud noises. Here are some common hazards and ways to stay safe:

- Loose clothing can get caught. Wear fitted clothes.

- Long hair should be tied back. It keeps you safe from moving parts.

- Check tools before use. A broken tool can cause injury.

Follow these steps, and you will have a safer time using a metal lathe!

What safety gear do I need for a metal lathe?

You should wear safety goggles, ear protection, and gloves. This gear keeps you safe from flying debris and loud noise.

Maintenance Tips for Longevity and Performance

Routine maintenance tasks to keep your lathe in top condition. Troubleshooting common issues during operation.

Keeping your lathe in good shape is important. Simple tasks help it run better and last longer. Regularly clean your lathe to remove dust. Check the oil levels and add oil as needed. Look for any loose parts and tighten them. If something doesn’t work, follow these steps:

- Stop the lathe immediately.

- Check for obvious problems, like broken pieces.

- Refer to the manual if you’re confused.

Taking care of your metal lathe ensures it stays reliable. This saves time and money in the long run.

What is the best way to maintain a metal lathe?

To maintain a metal lathe, clean it regularly and check the oil levels. Make sure everything is tight and working well. A little care goes a long way!

Advanced Techniques for Metal Lathe Users

Tips for precision machining and advanced operations. Resources for further skill development and training. To improve your skills on a metal lathe, focus on these advanced techniques. Start with precision machining. Use sharp tools for clean cuts. Check your measurements often. For further skill development, consider these resources:

- Online tutorials

- Workshops in your area

- Books on metalworking

Practice makes perfect! Remember, every expert was once a beginner. Learning different methods can help you become a better lathe user.

What are tips for precision machining?

Use high-quality tools. Regularly check your setup for accurate alignment. Clean your workspace to avoid mistakes.

Cost Considerations for a Metal Lathe Setup in 2025

Budgeting for the purchase: initial and ongoing costs. Evaluating ROI for home workshops vs. commercial use.

Buying a metal lathe in 2025 means considering two main costs: initial and ongoing. The initial cost is what you pay to buy the lathe. Ongoing costs include electricity, tools, and maintenance. For home workshops, investing in a lathe can be fun and educational. However, if it’s for commercial use, you should think about the return on investment (ROI). Will it help you make more money? Always plan your budget carefully to save money.

What should I consider for budgeting?

Start by asking yourself these key questions:

- How much will the lathe cost?

- What tools do I need to buy?

- How much will I spend on electricity?

Conclusion

In summary, setting up a metal lathe in 2025 focuses on precision and safety. Choose the right tools and make sure your workspace is organized. Don’t forget to learn about maintenance to keep everything running smoothly. We encourage you to explore guides or videos online for more tips. Start practicing and enjoy your metalworking journey!

FAQs

What Are The Key Specifications To Consider When Selecting A Metal Lathe For A Setup In 202

When choosing a metal lathe, think about size, power, and speed. The size should fit your workspace. More power helps you work with harder metals. You also want to pick a lathe with different speed settings. This way, you can choose how fast or slow you want to work.

How Can Automation And Smart Technology Enhance The Efficiency Of Metal Lathe Operations In 202

Automation and smart technology can make metal lathe operations faster and easier. They can help machines work on their own, so we don’t have to do everything by hand. This means we can make more parts in less time. Smart tools can also check their work to make sure everything is just right. This saves us time and helps us avoid mistakes.

What Advancements In Cutting Tools Should Be Integrated Into A Metal Lathe Setup For Optimal Performance In 202

To make a metal lathe work better, you should use new cutting tools. Try tools made from super hard materials like carbide. They stay sharp longer, so you can work faster. You can also use tools that can change shape for different jobs. Lastly, using automatic tool changers can save time and help you make neat pieces.

How Do Safety Features In Modern Metal Lathes Compare To Those From Previous Years For 20Setups?

Modern metal lathes have much better safety features than older ones. They often include automatic shut-off switches, which help prevent accidents if something goes wrong. There are also covers that protect you from flying pieces of metal. Old lathes didn’t have these features, making them riskier to use. Overall, we can feel safer when using new machines.

What Are The Best Practices For Maintaining A Metal Lathe To Ensure Longevity And Precision In A 20Workshop Environment?

To keep a metal lathe working well, we should clean it regularly. You can use a soft cloth to remove dust and oil. Check the moving parts and oil them to help them work smoothly. Make sure to tighten any loose screws or parts. Finally, always follow the user manual for any special tips!

Resource:

-

lathe maintenance best practices

URL: https://www.machinerylubrication.com/Read/28942/machine-tool-maintenance

Why: Perfect fit for your maintenance section -

Anchor Text: tool material comparison chart

URL: https://www.cnccookbook.com/cutting-tool-materials/

Why: Great for your advanced feature & tooling considerations -

Anchor Text: DIY lathe project inspiration

URL: https://www.instructables.com/Metalworking-Projects/

Why: Matches your “real-world applications” and inspires hobbyists -

Anchor Text: metalworking safety checklist

URL: https://www.ccohs.ca/oshanswers/safety_haz/machine_shop/metalworking.html

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Specifications To Consider When Selecting A Metal Lathe For A Setup In 202 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe, think about size, power, and speed. The size should fit your workspace. More power helps you work with harder metals. You also want to pick a lathe with different speed settings. This way, you can choose how fast or slow you want to work.”}},{“@type”: “Question”,”name”: “How Can Automation And Smart Technology Enhance The Efficiency Of Metal Lathe Operations In 202 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automation and smart technology can make metal lathe operations faster and easier. They can help machines work on their own, so we don’t have to do everything by hand. This means we can make more parts in less time. Smart tools can also check their work to make sure everything is just right. This saves us time and helps us avoid mistakes.”}},{“@type”: “Question”,”name”: “What Advancements In Cutting Tools Should Be Integrated Into A Metal Lathe Setup For Optimal Performance In 202 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe work better, you should use new cutting tools. Try tools made from super hard materials like carbide. They stay sharp longer, so you can work faster. You can also use tools that can change shape for different jobs. Lastly, using automatic tool changers can save time and help you make neat pieces.”}},{“@type”: “Question”,”name”: “How Do Safety Features In Modern Metal Lathes Compare To Those From Previous Years For 20Setups? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern metal lathes have much better safety features than older ones. They often include automatic shut-off switches, which help prevent accidents if something goes wrong. There are also covers that protect you from flying pieces of metal. Old lathes didn’t have these features, making them riskier to use. Overall, we can feel safer when using new machines.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining A Metal Lathe To Ensure Longevity And Precision In A 20Workshop Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, we should clean it regularly. You can use a soft cloth to remove dust and oil. Check the moving parts and oil them to help them work smoothly. Make sure to tighten any loose screws or parts. Finally, always follow the user manual for any special tips!”}}]}