Have you ever wondered how a simple piece of metal turns into a precise part? Automatic metal lathes make this magic happen. But did you know that the tools you use can change everything? Accessories for these machines can enhance how they work. They can make your projects easier and more fun.

Imagine you’re building a model of your dream car. With the right lathe accessories, you can create perfect parts quickly. Isn’t it fascinating how a small tool can lead to amazing results? Some accessories can even make your lathe safer to use.

In this article, we’ll explore the world of automatic metal lathe accessories. We’ll look at what they are and how they can help you. By the end, you’ll see why these tools are essential for any metalworking enthusiast. Get ready to discover new ways to upgrade your lathe experience!

Essential Automatic Metal Lathe Accessories For Optimal Performance

Exploring Automatic Metal Lathe Accessories

Automatic metal lathe accessories enhance your woodworking and metalworking experience. They include tool holders, quick change tooling, and coolant systems. These items increase efficiency and precision. Imagine finishing a project in less time! Did you know that adding the right accessories can even save energy? Choosing the right setup can make crafting easier and more fun. So, if you want to take your skills to the next level, consider upgrading your lathe with these handy accessories!Understanding Automatic Metal Lathes

Definition and functionality of automatic metal lathes. Key advantages of using automatic metal lathes in machining.Automatic metal lathes are machines that shape metal into various forms, kind of like how a chef shapes dough. They rotate the metal while cutting tools remove unwanted parts. This helps create precise items like gears and bolts quickly. One major advantage is speed; they can work faster than a human can say “Wow!” They also improve accuracy and reduce waste, making them a favorite in workshops. Remember, the quicker the lathe, the more time for snacks!

| Advantage | Description |

|---|---|

| Speed | Faster production time. |

| Accuracy | Consistent and precise results. |

| Reduced Waste | Minimizes material loss. |

Tool Holders and Their Importance

Various types of tool holders available for automatic lathes. How the right tool holder affects machining accuracy and speed.Tool holders are key parts of automatic metal lathes. They hold the cutting tools securely. Different types of tool holders exist. Some include collet chucks, screw-on holders, and quick-change holders. Choosing the right one matters. It affects how fast and accurately the machine works. A good tool holder can speed up production and improve quality.

What are the types of tool holders?

- Collet Chucks: These grip tools tightly for precision.

- Screw-on Holders: Easy to change and fit various tools.

- Quick-Change Holders: Allow fast swaps for efficiency.

How do tool holders impact machining?

Tool holders boost machining accuracy and speed. Right choices lead to better results.

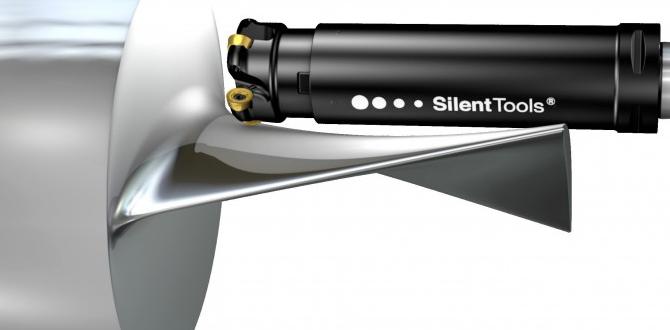

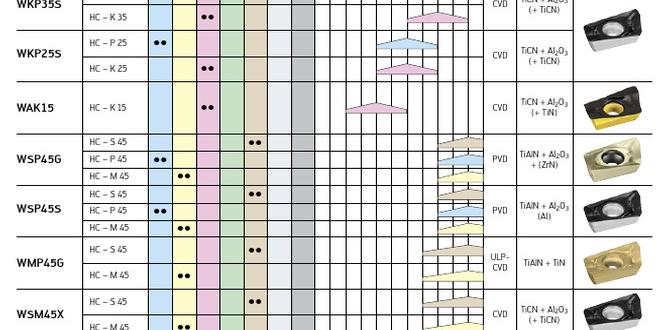

Cutting Tools: Types and Applications

Common cutting tools used with automatic metal lathes. Selection criteria based on material and desired finish.Every automatic metal lathe needs cutting tools. These tools come in different shapes and sizes, much like ice cream flavors. Some popular types include carbide inserts, high-speed steel (HSS) bits, and threading tools. Choosing the right one depends on the material you’re working with and the finish you want. For example, carbide inserts are great for tough metals, while HSS bits shine when working with softer materials.

| Tool Type | Best Material | Finish Quality |

|---|---|---|

| Carbide Inserts | Hard Metals | High |

| High-Speed Steel | Soft Materials | Medium |

| Threading Tools | Various | Precision |

So, pick wisely! Your cutting tool can make your work shine or turn it into a metal mess. Choose one that suits your material, and you’ll be ready to create awesome projects.

Chucks and Workholding Solutions

Types of chucks suitable for automatic metal lathes. The role of workholding solutions in enhancing productivity.Chucks are key tools for automatic metal lathes. They hold the metal pieces while the lathe works. There are types of chucks to choose from:

- Three-jaw chucks grip round pieces well.

- Four-jaw chucks hold square or irregular shapes securely.

- Collet chucks provide a tight grip for smaller parts.

Good workholding solutions can make work faster. They help keep the metal in place. This makes the job easier and safer. A reliable chuck can boost productivity by up to 30%!

What are the best types of chucks for metal lathes?

Three-jaw, four-jaw, and collet chucks are the best options. They hold materials securely and improve machining efficiency.

Coolants and Lubricants: Why They Matter

Types of coolants and lubricants for automatic lathe operations. Benefits of proper cooling and lubrication on tool life and machining quality.Coolants and lubricants keep your tools happy and healthy. Imagine trying to cook with a frying pan that has no oil! That’s how machines feel without proper cooling. There are many types of coolants, like water-soluble solutions and oil-based fluids. Each has its perks. Using the right one can make your tools last longer and cut more smoothly. Want your lathe to sing? Proper cooling can reduce friction and help maintain quality. Here’s a handy table:

| Type | Benefits |

|---|---|

| Water-Soluble | Great for cooling, easy to clean |

| Oil-Based | Superb for long-lasting lubrication |

In short, using the right coolants and lubricants can make all the difference. Remember, a happy machine is a productive machine!

Measuring Tools and Equipment

Importance of precision measuring tools in lathe machining. Recommended measuring equipment for automatic metal lathe users.Precision measuring tools are the superhero sidekicks of lathe machining! They ensure every cut is accurate, which keeps your projects on point. Without them, your metal can end up looking like a toddler’s art project—definitely not ideal! Recommended tools for automatic metal lathe users include calipers, micrometers, and depth gauges. Using these gadgets is like having super vision. Here’s a quick table to show you the best ones:

| Measuring Tool | Purpose |

|---|---|

| Calipers | Measure width and depth |

| Micrometers | Get super precise measurements |

| Depth Gauges | Check the depth of holes |

Don’t underestimate these tools! They make all the difference between a masterpiece and a mess.

Maintenance Accessories for Longevity

Key maintenance tools and accessories for automatic metal lathes. Best practices for maintaining accessories to ensure optimal performance.Keeping your tools running smoothly is important. Automatic metal lathe accessories require special care to last longer. A few key maintenance items make a big difference. Here are some essential accessories:

- Lubrication oil

- Cleaning brushes

- Tool holders

- Measuring gauges

Using these items correctly can help your tools work better. Regular cleaning and oiling are best practices. Always check for wear and tear. This way, your lathe will perform at its best!

How can I maintain my automatic metal lathe accessories?

Regular cleaning, proper lubrication, and timely replacements are the best ways. This ensures better performance and a longer lifespan for your accessories.

Conclusion

In conclusion, automatic metal lathe accessories enhance your machining experience. They improve accuracy, save time, and increase efficiency. With a range of tools available, you can customize your lathe to fit your needs. Explore these accessories to boost your skills and create better projects. Keep researching and experimenting to find what works best for you!FAQs

Sure! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Accessories:Automatic metal lathes are machines that shape metal. Accessories help them work better. You might need tools like tool holders to hold cutting tools. A steady rest helps to keep long pieces steady. You can also use a chuck to grab the metal piece tightly. These accessories make your projects easier and more fun!

Sure! Please provide me with the question you would like answered.

What Are The Essential Accessories Needed For Enhancing The Functionality Of An Automatic Metal Lathe?To make an automatic metal lathe work better, you need a few key accessories. First, a good set of cutting tools helps shape the metal. Second, a quality tool holder keeps those tools steady while you work. Third, a digital readout shows you exactly where to cut. Finally, a coolant system helps keep everything cool while you run the lathe. These tools make your projects easier and more fun!

How Do Various Tool Holders And Cutting Tools Impact The Precision And Efficiency Of Operations On An Automatic Metal Lathe?Tool holders and cutting tools are very important for automatic metal lathes. They help shape and cut metal pieces. If they fit well, we get more precise cuts and smoother surfaces. Good tools also work faster, so we finish jobs quickly. When we use the right tools, our work is cleaner and more accurate.

What Are The Advantages Of Using A Chip Conveyor With An Automatic Metal Lathe?A chip conveyor helps move metal scraps away from the automatic lathe. This keeps the work area clean and safe. It also helps the lathe run better and longer. You won’t have to stop working as much to clear away metal chips. That means more time to work and less time cleaning!

How Can Programmable Digital Readouts (Dro) Improve The Operation And Measurement Accuracy On An Automatic Metal Lathe?Programmable digital readouts (DRO) help you see exact measurements on a screen. This makes it easier to control the metal lathe. You get precise information, so your cuts are accurate. It also saves time because you don’t have to measure everything by hand. Overall, DRO makes working with the metal lathe faster and better.

What Safety Accessories Should Be Considered When Using An Automatic Metal Lathe To Ensure A Safe Working Environment?When using an automatic metal lathe, you should wear safety glasses to protect your eyes. Hearing protection, like earplugs, helps keep your ears safe from loud noises. Gloves can protect your hands, but make sure they fit well and won’t get caught in the machine. A face shield adds extra protection for your face. Lastly, keep the area clean and organized to prevent accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Accessories:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automatic metal lathes are machines that shape metal. Accessories help them work better. You might need tools like tool holders to hold cutting tools. A steady rest helps to keep long pieces steady. You can also use a chuck to grab the metal piece tightly. These accessories make your projects easier and more fun!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you would like answered.”}},{“@type”: “Question”,”name”: “What Are The Essential Accessories Needed For Enhancing The Functionality Of An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make an automatic metal lathe work better, you need a few key accessories. First, a good set of cutting tools helps shape the metal. Second, a quality tool holder keeps those tools steady while you work. Third, a digital readout shows you exactly where to cut. Finally, a coolant system helps keep everything cool while you run the lathe. These tools make your projects easier and more fun!”}},{“@type”: “Question”,”name”: “How Do Various Tool Holders And Cutting Tools Impact The Precision And Efficiency Of Operations On An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tool holders and cutting tools are very important for automatic metal lathes. They help shape and cut metal pieces. If they fit well, we get more precise cuts and smoother surfaces. Good tools also work faster, so we finish jobs quickly. When we use the right tools, our work is cleaner and more accurate.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Chip Conveyor With An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A chip conveyor helps move metal scraps away from the automatic lathe. This keeps the work area clean and safe. It also helps the lathe run better and longer. You won’t have to stop working as much to clear away metal chips. That means more time to work and less time cleaning!”}},{“@type”: “Question”,”name”: “How Can Programmable Digital Readouts (Dro) Improve The Operation And Measurement Accuracy On An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Programmable digital readouts (DRO) help you see exact measurements on a screen. This makes it easier to control the metal lathe. You get precise information, so your cuts are accurate. It also saves time because you don’t have to measure everything by hand. Overall, DRO makes working with the metal lathe faster and better.”}},{“@type”: “Question”,”name”: “What Safety Accessories Should Be Considered When Using An Automatic Metal Lathe To Ensure A Safe Working Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using an automatic metal lathe, you should wear safety glasses to protect your eyes. Hearing protection, like earplugs, helps keep your ears safe from loud noises. Gloves can protect your hands, but make sure they fit well and won’t get caught in the machine. A face shield adds extra protection for your face. Lastly, keep the area clean and organized to prevent accidents.”}}]}