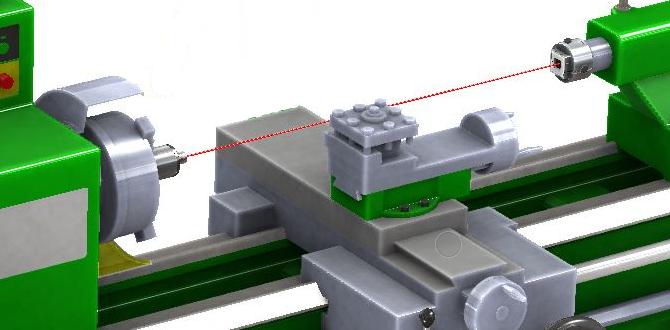

Have you ever wondered how metal parts are made with such precision? The secret often lies in machines called automatic metal lathes. These impressive tools can create complex shapes quickly. And it gets even better when you add advanced technology like CAD design.

Picture this: you want to build your own robot. You need metal parts that fit perfectly together. An automatic metal lathe could help you out. It can carve out the metal just the way you want it. But how do you design these parts before they are made? That’s where CAD, or computer-aided design, comes in.

With CAD design, you can create a detailed plan on your computer. Then, you send this plan right to the automatic metal lathe. It’s like giving the machine a blueprint. Isn’t that cool? You can see your ideas come to life in no time!

This article will explore how CAD design works with automatic metal lathes. You will discover tips for creating perfect designs and understand the magic behind it all. Get ready to dive into a world of creativity and technology!

Automatic Metal Lathe Cad Design: Enhancing Precision Engineering

Exploring Automatic Metal Lathe CAD Design

Automatic metal lathe CAD design opens up exciting possibilities for creating precise parts. This technology lets engineers design complex shapes effortlessly. Imagine a machine that can spin metal while a computer controls it! You learn how these lathes improve speed, accuracy, and reduce waste in manufacturing. A fun fact: the first lathes date back to ancient Egypt, evolving into today’s advanced CNC machines. Isn’t it fascinating how history shapes modern engineering?Understanding Automatic Metal Lathes

Definition and purpose of automatic metal lathes. Key components and functionality.Automatic metal lathes are machines that shape metal pieces quickly and accurately. Their main purpose is to create round and smooth parts. These lathes work by spinning the metal while cutting tools shape it. Key parts include:

- Spindle: Holds and spins the metal.

- Tool rest: Supports cutting tools.

- Motor: Powers the machine.

- Control system: Operates the lathe automatically.

With these components, automatic metal lathes help in making precise items efficiently.

What is the main benefit of using an automatic metal lathe?

The main benefit is increased accuracy and speed. These machines can produce parts that fit well and fast, which helps in many industries.

Benefits of Using CAD in Metal Lathe Design

Enhancements in precision and efficiency. Streamlined designtomanufacturing processes.Using CAD in metal lathe design improves precision and efficiency. It allows designers to create accurate models quickly. This technology speeds up the path from design to manufacturing. It helps to make fewer mistakes, saving both time and money.

- Enhances accuracy of parts.

- Reduces production time.

- Improves collaboration among teams.

Why is CAD important for metal lathe design?

CAD helps create better designs that fit perfectly, which means less waste and better products.

Key Design Considerations for Automatic Metal Lathes

Material selection and its impact on design. Design constraints and requirements.Picking the right materials for your automatic metal lathe can feel like searching for the last cookie in the jar—exciting and a bit tricky! The choice affects everything, from strength to weight. For instance, lighter materials can make the design zippier, but stronger ones ensure durability. Design constraints come next. Think about your workspace and safety rules. It’s important not to build a super gadget if it can’t fit through the door! Always keep in mind these key aspects: material type, usage needs, and compliance.

| Factors | Impact |

|---|---|

| Material Selection | Strength, weight, cost |

| Design Constraints | Space, safety regulations |

Creating a Metal Lathe Design: Step-by-Step Process

Initial planning and concept development. Detailed design procedures and best practices.First, start by planning your metal lathe design. Think about what parts you need and how they fit together. This is your chance to be creative! Draw sketches or use software to visualize your ideas. Next, dive into the detailed design. Follow these steps:

- Choose strong materials for durability.

- Focus on functionality and ease of use.

- Think about safety features.

These steps ensure a well-thought-out design and make a great automatic metal lathe.

What are the key steps in designing a metal lathe?

The key steps include planning ideas, selecting materials, and ensuring functionality. Following these steps helps create an effective design you will love to use.

Incorporating Automation in Metal Lathe Design

Understanding automation technologies in lathes. Advantages of automation in production efficiency.Automation in metal lathe design changes how we make things. It uses smart technology to help machines work faster and better. This means less time spent on each project. Here are some advantages:

- Increased speed: Machines can run quickly without breaks.

- Consistent quality: Each piece is made the same way every time.

- Less waste: Materials are used more efficiently.

Automation not only boosts production speed, but it also lowers costs. This helps companies create more products and satisfy customers better. Smarter machines are the future!

What are the benefits of automation in metal lathes?

Automation improves production efficiency by speeding up processes, ensuring consistent quality, and reducing material waste.

Common Challenges in Automatic Metal Lathe CAD Design

Identifying potential pitfalls in design. Strategies for overcoming design challenges.Designing an automatic metal lathe can feel like trying to solve a tricky puzzle. First, you might face issues like unclear specifications or software glitches. These hiccups can lead to errors. To avoid this, check your design details twice—don’t skip that math! Using good modeling software can also help. With smart planning and a pinch of patience, you can turn those challenges into a smooth ride.

| Challenge | Solution |

|---|---|

| Unclear specifications | Review and clarify details |

| Software glitches | Keep software updated |

| Error-prone designs | Use reliable modeling tools |

Case Studies: Successful Automatic Metal Lathe Projects

Analysis of realworld applications. Lessons learned from successful designs.Many projects using automatic metal lathe show how powerful these machines can be. For example, one factory improved their production speed by 30%. They learned designing with CAD made planning easier. Another project reduced waste by 20% using new designs. These successes teach us important lessons:

- Clear planning is key.

- Testing designs helps find problems early.

- Using technology improves results.

Every project adds to our knowledge, helping us build better machines.

What are some real-world applications of automatic metal lathe projects?

Real-world applications include creating parts for cars, making tools, and designing unique products.

Key benefits include:

- Increased efficiency

- Higher precision

- Cost savings

The Future of Automatic Metal Lathe CAD Design

Emerging trends and innovations in technology. Predictions for the future landscape of metal lathe design.The world of automatic metal lathe design is buzzing with excitement! New technologies are popping up faster than toast in a toaster. We’ll see smart machines that can think for themselves, making our work easier. Imagine a lathe that predicts when you need a break—no coffee needed! Experts believe that by 2030, designs will be more streamlined, and costs will drop significantly. Get ready for a future where metal lathes are not just machines, but your trusty sidekicks!

| Innovation | Benefit |

|---|---|

| AI Integration | Improved efficiency and accuracy. |

| 3D Printing | Faster prototyping and reduced waste. |

| Remote Operation | Control from anywhere, even in your pajamas! |

Conclusion

In summary, an automatic metal lathe CAD design can save time and improve accuracy. It helps you create precise parts easily. Understanding its features allows you to design better. Consider trying a CAD program if you haven’t already. Explore more resources to deepen your knowledge and practice your skills. Happy designing!FAQs

What Are The Key Design Considerations For Creating A Cad Model Of An Automatic Metal Lathe?When designing a CAD model of an automatic metal lathe, you need to think about a few important things. First, choose the right size for your lathe to fit your workspace. Second, make sure all the parts can move easily, like the tool holder and workpiece. Third, include safety features, like guards, to protect users. Finally, keep it simple so it’s easy to understand and use.

How Can Simulation Software Improve The Efficiency Of Designing An Automatic Metal Lathe In Cad?Simulation software helps us test designs before making anything. You can see how the metal lathe works in a computer model. This way, we fix any problems early. It saves time and materials, making designing faster and easier. Overall, we can create a better machine with less effort.

What Types Of Materials And Components Are Commonly Used In The Cad Design Of Automatic Metal Lathes?In CAD design for automatic metal lathes, we often use materials like steel and aluminum. These materials are strong and can handle heavy work. We also add components like motors, gears, and sensors. Motors help spin the lathe, gears help move it, and sensors make sure everything works correctly.

How Does The Integration Of Cnc Technology Enhance The Functionality Of A Cad-Designed Automatic Metal Lathe?CNC stands for Computer Numerical Control. It helps the metal lathe follow instructions from a computer. This means we can create precise shapes faster and easier. The lathe can work on its own, so we don’t have to do everything by hand. This makes our work more accurate and saves a lot of time!

What Are The Common Challenges Faced During The Cad Design Process Of An Automatic Metal Lathe, And How Can They Be Overcome?During the CAD (Computer-Aided Design) process for an automatic metal lathe, we often face a few challenges. One challenge is making sure all parts fit together correctly. We can fix this by checking our designs often and testing them with models. Another problem might be understanding how the machine will work in real life. You can overcome this by asking experts for advice or using videos to see how machines operate. Lastly, it can be hard to make the design easy to build. To solve this, we should keep designs simple and use clear instructions.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Design Considerations For Creating A Cad Model Of An Automatic Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a CAD model of an automatic metal lathe, you need to think about a few important things. First, choose the right size for your lathe to fit your workspace. Second, make sure all the parts can move easily, like the tool holder and workpiece. Third, include safety features, like guards, to protect users. Finally, keep it simple so it’s easy to understand and use.”}},{“@type”: “Question”,”name”: “How Can Simulation Software Improve The Efficiency Of Designing An Automatic Metal Lathe In Cad? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Simulation software helps us test designs before making anything. You can see how the metal lathe works in a computer model. This way, we fix any problems early. It saves time and materials, making designing faster and easier. Overall, we can create a better machine with less effort.”}},{“@type”: “Question”,”name”: “What Types Of Materials And Components Are Commonly Used In The Cad Design Of Automatic Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In CAD design for automatic metal lathes, we often use materials like steel and aluminum. These materials are strong and can handle heavy work. We also add components like motors, gears, and sensors. Motors help spin the lathe, gears help move it, and sensors make sure everything works correctly.”}},{“@type”: “Question”,”name”: “How Does The Integration Of Cnc Technology Enhance The Functionality Of A Cad-Designed Automatic Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC stands for Computer Numerical Control. It helps the metal lathe follow instructions from a computer. This means we can create precise shapes faster and easier. The lathe can work on its own, so we don’t have to do everything by hand. This makes our work more accurate and saves a lot of time!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During The Cad Design Process Of An Automatic Metal Lathe, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “During the CAD (Computer-Aided Design) process for an automatic metal lathe, we often face a few challenges. One challenge is making sure all parts fit together correctly. We can fix this by checking our designs often and testing them with models. Another problem might be understanding how the machine will work in real life. You can overcome this by asking experts for advice or using videos to see how machines operate. Lastly, it can be hard to make the design easy to build. To solve this, we should keep designs simple and use clear instructions.”}}]}