Have you ever wondered how metal parts are made? Machines can turn solid metal into beautiful shapes. One of those amazing machines is the automatic metal lathe drive system. This machine spins metal very fast and cuts it with precision. It’s like having a magic wand for metal!

Imagine a factory buzzing with activity. Workers and machines dance together in harmony. The automatic metal lathe drive system helps make this possible. With its smart features, it can adjust speed and power all by itself. This means better efficiency and fewer mistakes.

Did you know that the first lathes were made over 2,000 years ago? They have come a long way since then. Today’s automatic metal lathe drive systems are marvels of engineering. They make crafting parts easier and quicker. Wouldn’t it be exciting to see how this technology can change the way we create things?

In this article, we will explore how these machines work. We will also look at their advantages and why they are so popular. Get ready to dive into the world of automatic metal lathes!

Understanding Automatic Metal Lathe Drive System Benefits

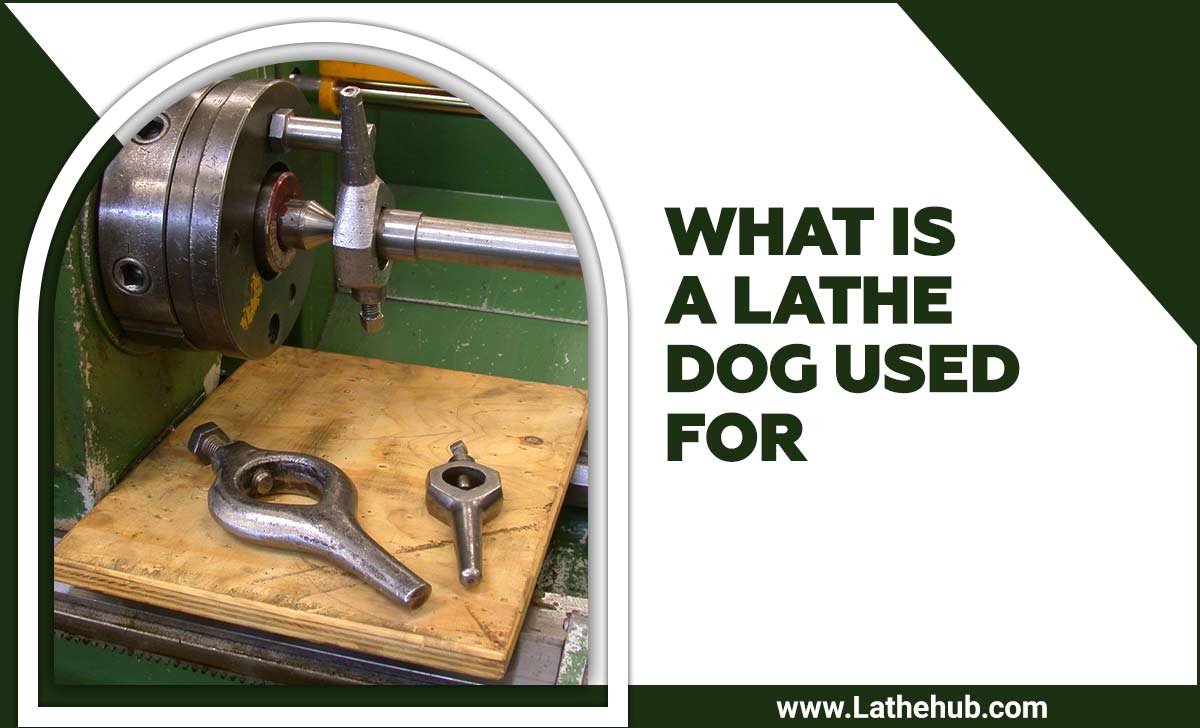

Automatic Metal Lathe Drive System

An automatic metal lathe drive system makes machining easier and more efficient. Imagine a busy factory where machines operate smoothly without constant human input. This system automates tasks like cutting and shaping metal, saving time and reducing errors. With advanced technology, these lathes offer precision and improved safety. Fun fact: some can automatically adjust their speed based on the material! This innovation transforms how industries manufacture parts and tools, making processes faster and more reliable.What is an Automatic Metal Lathe Drive System?

Definition and basic functionality. Historical evolution of drive systems in metal lathes.An automatic metal lathe drive system is a machine that shapes metal using spinning tools. It allows for precise cuts and helps create various parts quickly. Over time, these systems have evolved. Early lathes were powered by foot pedals or hand cranks. Later, electric motors made them faster and easier to use.

- Early Lathes: Used foot pedals.

- Mid 20th Century: Electric motors introduced.

- Today: Fully automatic systems improve speed and accuracy.

What is the function of an automatic metal lathe drive system?

The main function is to efficiently shape and cut metal into needed forms. It works by rotating the metal while a sharp tool removes material.

Components of an Automatic Metal Lathe Drive System

Motor types used: servo, stepper, and traditional. Control systems: CNC vs. manual controls.In an automatic metal lathe drive system, several key components work together to enable smooth operation. The motor types include:

- Servo motors: These provide precise control and speed.

- Stepper motors: These allow accurate positioning.

- Traditional motors: These are reliable but less precise.

The control systems can be either:

- CNC (Computer Numerical Control): This allows for advanced automation.

- Manual controls: These require a human operator for adjustments.

Each type has its own benefits, depending on what you need from the lathe.

What are common motors in an automatic metal lathe?

The most common motors are servo, stepper, and traditional motors. They help machines work faster and more accurately.

What type of control systems do they use?

Most systems use CNC for better automation. Some still use manual controls for hands-on operations.

Benefits of Using an Automatic Metal Lathe Drive System

Enhanced precision and repeatability. Increased productivity and efficiency.An automatic metal lathe drive system offers many benefits. It improves precision and ensures every cut is accurate. This means less waste and better quality! With such a system, machines can work faster. This leads to higher productivity and better efficiency. Factory workers can achieve more in less time. Everyone saves time and energy!

How does it enhance precision and productivity?

The automatic metal lathe drive system boosts accuracy and speed.

- Precision: Cuts are exact, reducing errors.

- Productivity: Faster machines produce more items.

Common Applications of Automatic Metal Lathe Drive Systems

Industries benefiting from this technology. Specific tasks and items produced.Many industries use automatic metal lathe drive systems to improve their work. Factories create items like parts for cars and machines. These lathes make precise cuts, saving time and boosting productivity. Imagine making a donut perfectly; that’s how these machines work with metal!

| Industry | Common Products |

|---|---|

| Automotive | Engine parts, shafts |

| Aerospace | Components, fittings |

| Manufacturing | Tools, fixtures |

| Medical | Instruments, implants |

This technology helps create everything from simple screws to complex machine parts rapidly. It makes jobs easier and keeps workers happy! Who wouldn’t want to work with a machine that does the hard stuff?

Comparison of Automatic vs. Manual Metal Lathe Drive Systems

Advantages of automation over manual processes. Cost implications and ROI analysis.Automation in metal lathe systems offers many benefits over manual methods. First, it can work faster and more accurately. This saves time and reduces errors. Second, automation can lower labor costs in the long run. Less human effort means more machines can work in a shorter time. Here’s a quick look at some advantages:

- Increased efficiency: Machines run longer without breaks.

- Consistency: Each item looks the same.

- Reduced waste: Fewer mistakes mean less scrap.

With an automatic metal lathe drive system, you might find a better return on investment. Although initial costs may be high, the long-term savings can outweigh them. Investing in technology can lead to better profits later on.

What are the main benefits of automatic metal lathe systems?

Automatic systems save time, reduce errors, and lower costs over time.

Key Points

- Faster production rates

- Less chance for mistakes

- More cost-effective in the long run

Maintenance and Troubleshooting of Automatic Metal Lathe Drive Systems

Routine maintenance practices. Common issues and solutions.To keep an automatic metal lathe drive system in great shape, routine maintenance is key. Regularly check the oil levels and change them as needed. Cleaning the gears and checking belts and bearings is also important to prevent problems. Here are some common issues and their solutions:

- Strange noises: This might mean the bearings are worn out. Replacing them can help.

- Variable speed issues: Check if the drive belt is loose or damaged. Tighten or replace it as necessary.

- Overheating: Make sure there is enough lubrication. Add oil to cool it down.

By following these basic steps, you can keep your machine running smoothly and avoid bigger issues down the road.

What are key routine maintenance practices?

Routine checks include oil changes and cleaning parts. Always look out for signs of wear.

Future Trends in Automatic Metal Lathe Drive Systems

Innovations on the horizon. Impact of IIoT and smart technologies.Exciting changes are coming for automatic metal lathe drive systems! Soon, innovations will make these machines even smarter. Imagine a lathe that can talk to other machines! That’s the power of IIoT, or Industrial Internet of Things. Smart tech will help predict problems before they happen. Less downtime means more fun for workers and better products. And who doesn’t want a lathe with a personality? This future is bright, and a touch quirky!

| Innovation | Impact |

|---|---|

| AI integration | Boosts efficiency |

| Remote monitoring | Reduces downtime |

| Predictive maintenance | Prevents disasters |

Choosing the Right Automatic Metal Lathe Drive System

Key factors to consider based on specific needs. Recommendations for different levels of production.Finding the right automatic metal lathe drive system can be tricky. Think about what you need first. Here are a few key factors:

- Type of materials: Consider if you’ll work with metals like steel or aluminum.

- Production Level: For small projects, a basic system works. For bigger tasks, look for a more advanced one.

- Budget: Know how much you can spend. Cheaper models exist, but they may lack features.

Each need is different, so match your choice to your projects!

What should I consider when choosing a metal lathe system?

Look for factors like material type, production level, and budget.

Recommendations:

- Small scale: Manual models for hobbyists.

- Medium scale: Mid-range options for small businesses.

- Large scale: Advanced systems for heavy industry needs.

Case Studies: Successful Implementations of Automatic Metal Lathe Drive Systems

Realworld examples of businesses improving operations. Lessons learned and best practices.Many businesses have successfully used automatic metal lathe drive systems to boost their operations. For instance, a local factory switched to this system. They saw a 30% increase in production speed! Another company reduced waste by 20% using precise measurements from their automatic lathes.

Here are some important lessons learned:

- Better accuracy leads to less waste.

- Speeding up production can cut costs.

- Regular maintenance keeps machines running well.

These examples show how effective automatic systems can be. It helps companies grow and work smarter.

What are some real-world examples of businesses using automatic metal lathe drive systems?

Examples include factories that increased production and companies that saved materials. These successes prove that these systems work well in many settings.

Conclusion

In summary, an automatic metal lathe drive system enhances efficiency and precision in metalworking. It allows you to work faster and produce better results. Understanding how this system functions can help you improve your projects. We encourage you to explore more about lathe systems and consider trying one in your next project. It’s a great way to boost your skills!FAQs

Sure! Here Are Five Questions Related To The Automatic Metal Lathe Drive System:Sure! Here are five questions about the automatic metal lathe drive system: 1. **What is a metal lathe?** A metal lathe is a machine that shapes metal. It spins the metal while a tool cuts it. 2. **How does the drive system work?** The drive system makes the lathe spin. It uses a motor to power the machine. 3. **Why is the drive system important?** The drive system is important because it helps the lathe work smoothly. It keeps everything running well. 4. **What parts are in the drive system?** The drive system has a motor, belts, and gears. These parts help move the lathe. 5. **Can we adjust the speed?** Yes, we can adjust the speed of the lathe. This helps us make different shapes and sizes of metal.

Sure! Just let me know what question you’d like me to answer.

What Are The Key Components Of An Automatic Metal Lathe Drive System, And How Do They Work Together To Enhance Machining Efficiency?An automatic metal lathe drive system has a few key parts. First, there’s the motor, which powers the machine. Then, we have gears that help change the speed and direction. Finally, we have controls that let you adjust settings easily. Together, these parts help the machine cut metal quickly and accurately, making our work faster and better!

How Does The Use Of Servo Motors In The Drive System Of An Automatic Metal Lathe Improve Precision And Control Over Traditional Drive Methods?Servo motors help automatic metal lathes work better than older methods. They move parts very smoothly and accurately. This means we get better cuts on the metal. You can control the speed and position easily, making it perfect for any task. Using servo motors helps us create more precise shapes and sizes.

What Are The Advantages Of Integrating Computer Numerical Control (Cnc) Systems Into Automatic Metal Lathe Drive Systems, Particularly In Terms Of Automation And Repeatability?Integrating CNC, which means Computer Numerical Control, into metal lathes helps machines work better. It makes the machines do the same task perfectly every time. This means you don’t have to worry about mistakes. Automation lets machines run without much help from people, saving time and effort. Overall, CNC makes metal working faster and more accurate!

How Does The Selection Of Different Drive Mechanisms (Such As Belt, Direct, Or Gear Drive) Impact The Performance And Maintenance Of An Automatic Metal Lathe?Choosing a drive mechanism for a metal lathe affects how well it works. A belt drive is quiet and easy to maintain, but it can slip. A direct drive makes it more powerful but can be harder to fix. A gear drive can handle tough jobs but might require more maintenance. Each choice affects both performance and how often you need to repair it.

What Role Does Software Play In Optimizing The Performance Of An Automatic Metal Lathe Drive System, And What Types Of Programming Languages Or Interfaces Are Commonly Used?Software helps an automatic metal lathe drive system work better. It tells the machine how to move and cut metal. This makes the work faster and more accurate. We often use programming languages like C++ or Python to write the software. These languages help us give clear instructions to the machine.