Have you ever wondered how machines work with such precision? One key part is the foot brake on an automatic metal lathe. This clever tool helps control speed and stops the machine quickly when needed.

Imagine a busy workshop where metal parts are shaped. Suddenly, an unexpected problem arises. The operator swiftly presses the foot brake, halting the spinning metal. This quick action prevents accidents and ensures safety.

Did you know that foot brakes can make a big difference in how smoothly the lathe runs? They allow operators to focus on their work without worrying about stopping the machine. It’s like having a safety net while performing amazing tasks!

This article dives deeper into the amazing world of automatic metal lathe foot brakes. Keep reading to discover how they work and why they are essential for every workshop.

The Importance Of An Automatic Metal Lathe Foot Brake

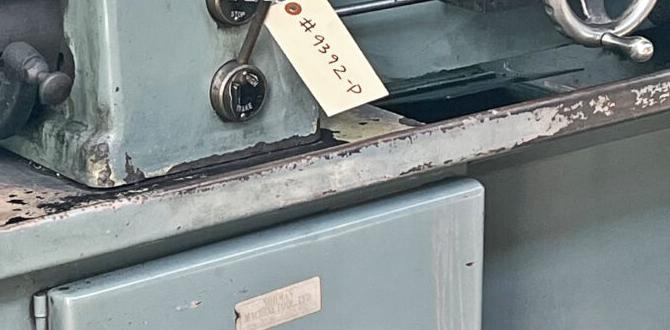

Automatic Metal Lathe Foot Brake

Are you curious about the benefits of an automatic metal lathe foot brake? This handy feature enhances safety and efficiency in metalworking. Whenever you need to stop quickly, the foot brake allows for immediate control. It frees up your hands, making tasks easier and safer. Imagine working on delicate pieces without worrying about accidents! Plus, it reduces strain during long hours. Overall, a foot brake on your lathe could make a fun and productive project even better.What is an Automatic Metal Lathe Foot Brake?

Definition and purpose of an automatic foot brake. Differences between manual and automatic foot brakes.An automatic metal lathe foot brake is a safety feature that stops the machine quickly. Its purpose is to protect users from accidents. With an automatic brake, the machine halts as soon as the foot is removed from the pedal. This is different from manual brakes, which need more effort to stop. Here’s a quick look at both:

- Automatic Foot Brake: Stops instantly when the pedal is released.

- Manual Foot Brake: Requires you to push down and hold to stop.

This makes automatic brakes safer and easier for users.

What are the advantages of automatic metal lathe foot brakes?

Automatic brakes reduce accidents and increase productivity. By stopping quickly, they help users focus on their tasks without worry.

Benefits of Using an Automatic Foot Brake

Enhanced safety measures for operators. Increased efficiency in metal lathe operations.Using an automatic foot brake on a metal lathe comes with great perks! Firstly, it greatly improves safety for operators. No more accidental slips that could lead to accidents—it’s like having a superhero in the workshop! Also, it boosts efficiency. Parts finish faster, which means you can impress your boss and maybe even get a donut as a reward!

| Benefit | Description |

|---|---|

| Enhanced Safety | Reduces accidents and gives operators peace of mind. |

| Increased Efficiency | Speeds up metal lathe operations for quicker projects. |

In a world where speed and safety matter, the automatic foot brake is a game-changer!

How Automatic Foot Brakes Work

Technical explanation of the mechanism. Components involved in functionality.Automatic foot brakes are cool gadgets! They stop spinning machines in a snap. The magic happens when you push the pedal. This sends a signal to the brake mechanism, using gears and hydraulic fluid to activate the brake pads. These pads are the heroes, gripping the metal to halt it. Less squealing, more safety! Here’s a quick look at some key parts:

| Component | Function |

|---|---|

| Pedal | Triggers the brake system |

| Brake Pads | Grip the metal to stop movement |

| Hydraulic System | Transmits force to the brakes |

| Gears | Help control the braking process |

This system is like a superhero team. Together, they make sure tools stop when you need them to. Safety first, right?

Installation and Setup Process

Stepbystep guide for installation. Common pitfalls and troubleshooting tips.Setting up an automatic metal lathe foot brake can be fun and challenging! First, gather all the parts and tools. It’s like a treasure hunt—just without the map. Start by attaching the brake to the lathe according to your manual. Remember, not all screws fit in all holes—kind of like trying to wear your big brother’s shoes!

Common pitfalls include forgetting to tighten bolts. If things wiggle, your brake might feel like it’s dancing. If you run into trouble, check your connections. A loose wire can make it act like a grumpy cat. Here’s a handy troubleshooting guide:

| Problem | Solution |

|---|---|

| Brake not engaging | Check the wiring connections. |

| Unusual noises | Tighten all screws. |

| Brake feels soft | Inspect for air bubbles in the system. |

Remember, practice makes perfect. Soon, you’ll be a pro at setting up your lathe brake! And who knows? Maybe you’ll even impress your cat with your skills!

Maintenance Tips for Longevity

Routine checks and servicing recommendations. Signs of wear and how to address them.To keep your automatic metal lathe foot brake working well, follow these easy tips. Regular checks help find problems early. Look for signs of wear, like strange noises or loose parts. Fixing these fast can save you time and money. Regularly lubricate parts to keep them moving smoothly. Consider a service check every few months.

- Check parts for wear.

- Oil moving parts.

- Listen for odd sounds.

- Fix loose components quickly.

What are signs that my equipment needs maintenance?

If you notice odd noises or parts that feel loose, it’s time to check. Keep an eye on performance. If something feels off, act right away to avoid bigger problems.

Real-World Applications and Case Studies

Industries that benefit from automatic foot brakes. Testimonials from users regarding performance improvements.Many industries find automatic metal lathe foot brakes useful. They help improve safety and efficiency. Here are some sectors that benefit:

- Manufacturing

- Aerospace

- Automotive

- Medical equipment

Users have praised these brakes. They report better control and faster operation. One user stated, “My mistakes were halved!” This shows how these brakes make a real difference.

What are the benefits of automatic foot brakes?

The benefits include increased safety, improved productivity, and reduced errors. They make work smoother and safer for everyone.

Cost Considerations and Budgeting

Breakdown of costs associated with purchase and installation. Longterm savings and productivity gains.Understanding the costs of an automatic metal lathe foot brake can help you budget wisely. You need to think about both buying and installing it. Here’s a quick look at the costs:

- Initial Purchase: Price varies based on brand and features.

- Installation: Hiring a professional can add to the cost.

- Maintenance: Regular checks ensure it lasts longer.

However, investing now can lead to long-term savings. You’ll likely see:

- Less waste and mistakes in your metalwork.

- Faster production speeds, leading to better profits.

This means spending upfront could pay off in the long run!

How can an automatic metal lathe foot brake save money?

It cuts down on errors and boosts production speed. You’ll spend less on materials and time. This can lead to savings that add up over the years!

Future Trends in Automatic Foot Brake Technology

Innovations in design and functionality. Predictions for industry advancements.New ideas for automatic foot brake technology are exciting. Designers are making brakes safer and easier to use. They focus on better materials and smarter controls. Predictions for the future show these brakes will be more efficient. Factories might see a rise in use due to increased safety.

- Smart sensors will improve response time.

- Brakes will be lighter, making machines easier to handle.

- More energy-efficient designs will save resources.

Experts believe these advancements will change the industry. More machines using these brakes mean safer workplaces. Greater efficiency may also lead to lower costs, benefiting everyone.

What innovations can we expect in automatic foot brake technology?

Designs will become smarter, using sensors to ensure safety while improving efficiency.

Conclusion

In summary, an automatic metal lathe foot brake enhances safety and control while you work. It allows you to stop the machine quickly, preventing accidents. Understanding how it works helps you use your lathe more effectively. We encourage you to explore this topic further to ensure safe and efficient operation. Always prioritize safety in your projects!FAQs

What Are The Primary Safety Features Of An Automatic Metal Lathe Foot Brake, And How Do They Enhance Operator Safety?An automatic metal lathe foot brake helps keep you safe while working. When you press the foot brake, it stops the machine quickly. This means you can stop the lathe fast if something goes wrong. The brake also helps prevent accidents by letting you focus on your work without worrying. These features make the machine safer and help protect you from getting hurt.

How Does The Design And Functionality Of Foot Brakes In Automatic Metal Lathes Differ From Traditional Hand-Operated Brakes?Foot brakes on automatic metal lathes work by using your foot to stop the machine easily. You press down on a pedal, and it quickly halts the lathe. In contrast, traditional hand-operated brakes need your hand to pull a lever. This means you have to reach away from your work to stop the machine. Foot brakes help you keep your hands free to work better and safer.

What Maintenance Procedures Are Recommended To Ensure The Reliable Operation Of Foot Brakes In Automatic Metal Lathes?To keep foot brakes working well on automatic metal lathes, check them often for dirt or damage. Clean the brakes regularly to remove dust and grease. Also, make sure the brake parts are not worn out and replace them if they are. Finally, test the brakes to ensure they stop the machine quickly and safely whenever you use them.

How Can The Integration Of Foot Brakes Into Automatic Metal Lathes Improve Efficiency And Productivity In Machining Operations?Adding foot brakes to automatic metal lathes makes work easier and faster. You can stop the machine quickly with your foot, so you don’t have to reach for buttons. This saves time and helps you keep your focus on what you’re making. It also makes things safer because you can control the machine without using your hands. Overall, this helps you work better and finish tasks quicker!

What Are Common Issues Or Failures Associated With Foot Brakes In Automatic Metal Lathes, And How Can They Be Diagnosed And Resolved?Foot brakes in automatic metal lathes can have several problems. Sometimes, they might not stop the machine properly. This can happen if the brake system is dirty or worn out. You can check for dirt and clean it. If it’s broken, you might need to replace parts. Always make sure to follow safety steps when fixing them.