Imagine watching a giant, spinning machine that can turn a block of metal into a beautiful shape. That’s what an automatic metal lathe gear does! This amazing tool helps engineers and hobbyists make precise parts for machines, toys, and even cars.

Have you ever wondered how those tiny gears in your favorite action figure work? They are often made using an automatic metal lathe. This machine turns metal with incredible speed and accuracy. It allows for quick and efficient creations that many people take for granted.

Did you know that some lathes are so advanced they can work on their own? Yes, they can! With software and technology, these automatic metal lathe gears finish tasks while we focus on other things. Isn’t that cool?

In this article, we will explore how these machines operate. We’ll learn why they are essential in today’s world. By the end, you’ll see how an automatic metal lathe gear can change the way we create and build things.

Exploring The Benefits Of An Automatic Metal Lathe Gear

Understanding Automatic Metal Lathe Gear

Automatic metal lathe gears transform metal pieces with precision. Have you ever watched a machine shape metal? They help create everything from tiny screws to big engine parts. These gears make the process faster and more accurate. Most lathes use different gear ratios for various tasks. Did you know that with the right gear, even complex shapes can be made easily? Learning about these gears opens up a world of creativity in metalworking.What is an Automatic Metal Lathe?

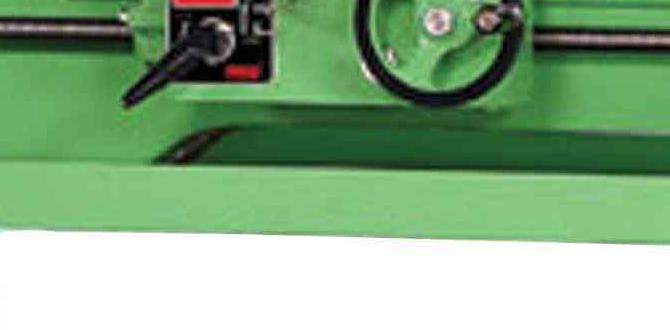

Definition and basic functionality. Historical development and evolution in manufacturing.An automatic metal lathe is a machine that shapes metal into different forms. Picture it as a magic wand for metal! It spins and cuts metal pieces, making them into rods, cylinders, and other shapes. This amazing gadget has changed a lot since its beginnings in the 18th century when it was powered by hand. Now, thanks to technology, it’s fast and precise!

| Feature | Old Lathes | Automatic Lathes |

|---|---|---|

| Power Source | Manual | Electric |

| Speed | Slow | Fast |

| Accuracy | Limited | High |

Today’s lathes are smart and can work on their own, saving us time for more important things, like perfecting our cookie recipe! They’ve come a long way from their old-fashioned cousins!

Components of Automatic Metal Lathes

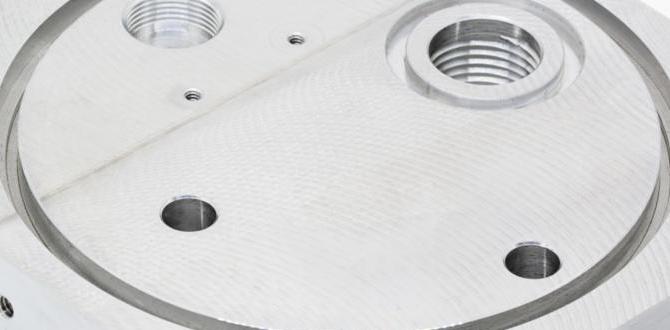

Detailed breakdown of essential parts: spindle, feed mechanism, tool holder, etc.. Importance of each component in the lathe’s operation.Every automatic metal lathe has key parts that help it work well. The spindle spins the metal, making it ready for shaping. The feed mechanism moves the metal in and out smoothly. The tool holder keeps the cutting tools steady during operation. Each piece plays an important role, ensuring accuracy and efficiency in creating pieces. Without these components, the lathe would struggle to perform its task.

Why Are These Components Important?

Each component is vital for smooth operation. The spindle helps in shaping the metal. The feed mechanism ensures the metal aligns perfectly. The tool holder secures tools for precise cuts.

Key Components:

- Spindle: Spins the workpiece.

- Feed Mechanism: Moves the metal carefully.

- Tool Holder: Supports the cutting tools.

Advantages of Using Automatic Metal Lathes

Increased precision and accuracy in machining. Enhanced productivity and efficiency.Using an automatic metal lathe has some great benefits. First, it offers increased precision and accuracy. This means each part is made just right. You get less waste and better quality. Second, automatic lathes also boost productivity and efficiency. They can work faster than a person, helping factories get more done. This way, businesses can save time and money, making everyone happy.

What are the key advantages of automatic metal lathes?

Many benefits come from using automatic metal lathes. They improve output and precision, making them a smart choice for many industries.

- Less material waste

- Work with high speed

- Less chance for mistakes

- Easy to program for different tasks

Applications of Automatic Metal Lathes

Key industries utilizing automatic metal lathes (aerospace, automotive, etc.). Examples of products and parts manufactured using automatic lathes.Many industries use automatic metal lathes for making precise parts. The aerospace and automotive sectors rely on these machines for efficiency. Automatic lathes help produce high-quality items quickly. Examples of products include:

- Engine parts for cars

- Aircraft components

- Precision screws and fasteners

With these machines, manufacturers can create strong and reliable products. This saves time and reduces waste, making it a smart choice for businesses.

What industries use automatic metal lathes?

Aerospace, automotive, and manufacturing industries are the main users of automatic metal lathes.

What parts are made using these lathes?

- Fasteners

- Shafts

- Brackets

Choosing the Right Automatic Metal Lathe for Your Shop

Factors to consider: size, capability, software, and budget. Importance of aligning equipment with specific manufacturing needs.Finding the perfect automatic metal lathe for your shop is important. You must think about several factors. Start with size. Will it fit in your workspace? Next, consider capability. Can it do the tasks you need? Software is also key. Does it have user-friendly controls? Lastly, think about your budget. How much can you spend? Choosing the right machine helps you meet your specific manufacturing needs.

- Size: Make sure it fits in your shop.

- Capability: Ensure it can handle your tasks.

- Software: Look for easy-to-use controls.

- Budget: Stick to your spending limit.

Why is it important to align equipment with manufacturing needs?

Aligning your equipment with specific needs ensures you work efficiently and produce quality products.Maintenance Tips for Automatic Metal Lathes

Essential maintenance practices to ensure longevity. Common issues and troubleshooting techniques.Taking care of an automatic metal lathe is important for its long life. Here are some tips to keep it running smoothly:

- Check oil levels weekly. Proper lubrication helps parts move freely.

- Clean the machine regularly. Dirt can cause wear and tear.

- Inspect belts and gears. Worn parts can lead to problems.

- Keep your workspace tidy. A clutter-free area helps prevent accidents.

If you notice strange noises or vibrations, stop using the machine. These often indicate issues. Address them early to avoid further damage.

What are common issues with automatic metal lathes?

Common issues include excessive noise, uneven cuts, and vibrations. These problems can be signs of parts needing attention.

How can you troubleshoot an automatic metal lathe?

Start with a simple inspection. Look for loose connections or worn parts. If the problem persists, consult the user manual for specific advice.

Future Trends in Automatic Metal Lathe Technology

Innovations in automation and AI integration. The impact of Industry 4.0 on lathe manufacturing processes.New ideas are changing automatic metal lathe technology fast. Automation and AI are making machines smarter. They can work without much help from people. This saves time and money. Industry 4.0 is also changing how we make things. It connects machines to the internet. This helps factories run smoother. Together, these changes make production faster and safer.

- More robots and AI will work on lathes.

- Real-time data makes better decisions.

- Factories will become more connected.

What is the future of automatic metal lathe technology?

The future looks bright. AI and automation will lead to faster and safer manufacturing. Machines will communicate and improve their work. More companies will adopt these technologies to stay competitive.

Cost Considerations for Automatic Metal Lathes

Breakdown of initial investment vs. operational costs. Financing options and return on investment analysis.Investing in an automatic metal lathe can be exciting and a bit tricky. First, think about the initial investment. This cost includes the price of the lathe itself and any setup needed. Next, consider operational costs. These are costs for running the machine, such as electricity, tools, and repairs. You might find financing options like loans or leasing. It’s smart to analyze your return on investment to see how quickly your purchase will pay off.

What are the costs of automatic metal lathes?

Costs vary widely. The initial price can be around $5,000 to $50,000, while operational costs may reach $1,000 to $5,000 yearly, depending on usage.

Key Points:

- Initial investment includes purchase price and setup.

- Operational costs cover electricity and maintenance.

- Financing options like loans or leases can help with the upfront cost.

- Return on investment measures how quickly you earn back your money.

Case Studies: Successful Implementations of Automatic Metal Lathes

Realworld examples showcasing efficiency gained. Lessons learned from various manufacturing setups.Many factories have seen great success using automatic metal lathe gear. These machines help save time and money. For instance, one company reduced its production time by 30%. Another learned that proper training led to fewer mistakes. Here are some important lessons:

- Invest in worker training.

- Regular maintenance keeps machines running smoothly.

- Track productivity to identify areas for improvement.

Success stories show how choosing the right tools can transform a workplace.

What are the benefits of using automatic metal lathe gear?

Using automatic metal lathe gear boosts efficiency and reduces costs in production.Conclusion

In conclusion, an automatic metal lathe gear is essential for precision in shaping metal parts. It improves efficiency and saves time. You can make complex designs easily with this machine. If you want to learn more, explore basic lathe operations or watch tutorial videos online. Understanding these tools can help you in future projects or hobbies!FAQs

What Are The Key Features Of An Automatic Metal Lathe Gear System That Distinguish It From Manual Lathes?An automatic metal lathe uses motors to move the parts, while manual lathes need you to turn knobs. It can run quickly and make many pieces without stopping. You can set it to work on its own, so you don’t have to watch it all the time. This saves you time and helps make work easier and faster.

How Does The Gear Ratio In An Automatic Metal Lathe Affect The Cutting Speed And Precision Of The Machining Process?The gear ratio in an automatic metal lathe helps decide how fast the machine spins. A higher gear ratio means faster cutting, which is good for big jobs. But if it’s too fast, it can make cutting less accurate. So, we need to find the right balance for speed and precision. This helps us make better parts without mistakes.

What Maintenance Practices Are Essential For Ensuring The Longevity And Reliability Of Gear Systems In Automatic Metal Lathes?To keep gear systems in automatic metal lathes working well, you should do a few important things. First, check the oil levels regularly and add oil when needed. Next, make sure to clean any dust or chips off the gears. You should also look for wear and tear on parts and replace them if they are damaged. Finally, always follow the manufacturer’s instructions for care and maintenance.

How Do Advancements In Gear Technology Impact The Overall Efficiency And Performance Of Automatic Metal Lathes?Advancements in gear technology help automatic metal lathes work better and faster. New gears can move parts smoothly with less effort. This means machines can finish jobs quickly and accurately. When machines work well, it saves time and money. Overall, better gears make lathes stronger and more reliable.

What Types Of Materials Are Typically Used For Gears In Automatic Metal Lathes, And How Do They Influence The Machine’S Durability And Performance?Gears in automatic metal lathes are often made from steel or plastic. Steel gears are strong and last a long time. They help the machine work better because they don’t break easily. Plastic gears are lighter and can be quieter but may wear out faster. The choice of material affects how well the machine runs and how long it lasts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features Of An Automatic Metal Lathe Gear System That Distinguish It From Manual Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “An automatic metal lathe uses motors to move the parts, while manual lathes need you to turn knobs. It can run quickly and make many pieces without stopping. You can set it to work on its own, so you don’t have to watch it all the time. This saves you time and helps make work easier and faster.”}},{“@type”: “Question”,”name”: “How Does The Gear Ratio In An Automatic Metal Lathe Affect The Cutting Speed And Precision Of The Machining Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio in an automatic metal lathe helps decide how fast the machine spins. A higher gear ratio means faster cutting, which is good for big jobs. But if it’s too fast, it can make cutting less accurate. So, we need to find the right balance for speed and precision. This helps us make better parts without mistakes.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Longevity And Reliability Of Gear Systems In Automatic Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep gear systems in automatic metal lathes working well, you should do a few important things. First, check the oil levels regularly and add oil when needed. Next, make sure to clean any dust or chips off the gears. You should also look for wear and tear on parts and replace them if they are damaged. Finally, always follow the manufacturer’s instructions for care and maintenance.”}},{“@type”: “Question”,”name”: “How Do Advancements In Gear Technology Impact The Overall Efficiency And Performance Of Automatic Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advancements in gear technology help automatic metal lathes work better and faster. New gears can move parts smoothly with less effort. This means machines can finish jobs quickly and accurately. When machines work well, it saves time and money. Overall, better gears make lathes stronger and more reliable.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Typically Used For Gears In Automatic Metal Lathes, And How Do They Influence The Machine’S Durability And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gears in automatic metal lathes are often made from steel or plastic. Steel gears are strong and last a long time. They help the machine work better because they don’t break easily. Plastic gears are lighter and can be quieter but may wear out faster. The choice of material affects how well the machine runs and how long it lasts.”}}]}