Have you ever watched a skilled craftsman shape metal? It’s fascinating to see how they create precise parts using machines. One important tool in this process is the automatic metal lathe handwheel. But what exactly is it, and why is it so special?

The handwheel helps control the lathe’s movements. This allows workers to create everything from small gears to large shafts. Imagine spinning a wheel that shapes metal with perfect accuracy. Isn’t that amazing?

With the automatic metal lathe handwheel, every turn takes you closer to a finished product. It makes the job easier and faster. As you read this article, you will discover how this tool works and why many people in the industry love it. Prepare to dive into the world of metalworking!

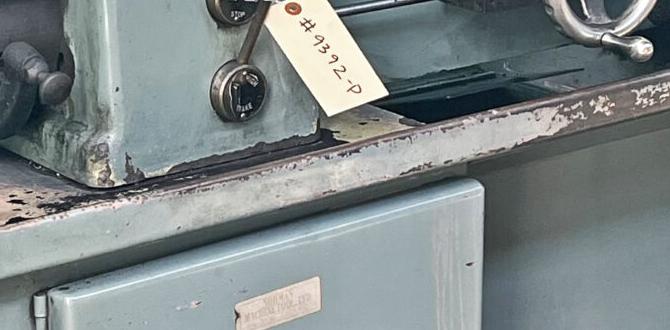

Automatic Metal Lathe Handwheel: Enhancing Precision Control

Understanding the Automatic Metal Lathe Handwheel

The automatic metal lathe handwheel is a key tool in metalworking. It helps control the movement of the lathe smoothly. Did you know that it can make even small adjustments? This precision allows for detailed work on metal pieces. Users find it easier to manipulate materials without losing control. For hobbyists and professionals alike, the handwheel enhances accuracy and creativity. Imagine crafting intricate designs effortlessly! It’s more than just a tool; it’s a game-changer in machining.What is an Automatic Metal Lathe Handwheel?

Definition and functionality. Importance in metalworking processes.An automatic metal lathe handwheel is a special tool used in workshops. It helps move the lathe parts smoothly and easily. Imagine steering a fancy race car—this handwheel does something similar! It makes turning metal simpler and faster. Why is it important? Well, it boosts efficiency in metalworking processes, saving time and effort. Less struggle means more time for creativity, like figuring out how to make a metal dinosaur. Talk about a roaring good time!

| Function | Importance |

|---|---|

| Smooth Movement | Increases Efficiency |

| User-Friendly | Reduces Frustration |

| Precise Control | Improves Accuracy |

Key Features of Automatic Metal Lathe Handwheels

Types of automatic handwheels available. Material and durability considerations.The automatic metal lathe handwheel comes in different styles to fit various machines and workshops. There are manual handwheels, which are great for hands-on control, and digital handwheels that make the process smoother with precise settings. Durability is key! They are often made from high-quality metals or strong plastics, ensuring they can handle the pressure without wearing out. Remember, a sturdy handwheel is like a trusty sidekick—you need it to stay strong during long jobs!

| Type | Material | Durability |

|---|---|---|

| Manual Handwheel | High-Quality Steel | Very Durable |

| Digital Handwheel | Reinforced Plastic | Durable but Lightweight |

Benefits of Using an Automatic Metal Lathe Handwheel

Enhanced precision in machining. Increased productivity and efficiency.Using an automatic metal lathe handwheel offers many benefits. First, it allows for enhanced precision in machining. This means cuts are cleaner and more exact. Second, it boosts productivity and efficiency. Workers can accomplish tasks faster and with less effort. Imagine finishing a project in half the time with perfect results!

- Better accuracy in every cut.

- Less time wasted on adjustments.

- More parts produced daily.

What Makes an Automatic Metal Lathe Handwheel Powerful?

The automatic metal lathe handwheel helps reduce errors. It saves time and boosts production! Many workers notice a significant change right away.

How to Choose the Right Automatic Metal Lathe Handwheel

Factors to consider (size, compatibility, brand). Recommendations for various applications.Choosing the right handwheel is key for your automatic metal lathe. Start by looking at the size. It should fit your machine perfectly. Next, check for compatibility. Some handwheels work better with specific brands. Lastly, think about the brand itself. Reputable brands often offer better quality. Here are some recommendations:

- For hobby projects, consider smaller, lighter models.

- For heavy-duty tasks, select a sturdy, industrial-grade option.

- Research brand reviews to ensure reliability.

What should I consider when buying a handwheel?

Consider size, compatibility with your lathe, and brand reputation.Installation and Setup of an Automatic Metal Lathe Handwheel

Stepbystep installation process. Common issues during setup and solutions.Installing an automatic metal lathe handwheel can feel like putting together a puzzle. Start by securing the handwheel onto the lathe with the provided bolts. Make sure it spins like your favorite top! If it wiggles more than your dog when you say “walk,” tighten those bolts.

| Common Issues | Solutions |

|---|---|

| Handwheel not turning | Check if it’s tightly mounted. |

| Strange noises | Lubricate the connections. |

Sometimes, things don’t go as planned. If it feels stuck, give it a gentle push, but not like you’re trying to start a stubborn car! Following these steps will help ensure a smooth setup. Happy lathe-ing!

Maintenance Tips for Automatic Metal Lathe Handwheels

Regular maintenance practices. Signs that maintenance is needed.To keep your automatic metal lathe handwheel in great shape, regular care is key. Here are some easy maintenance practices:

- Check for dirt and clean it often.

- Look for any loose parts and tighten them.

- Lubricate moving parts to reduce wear.

Sometimes, you can spot when maintenance is needed. Watch for these signs:

- The handwheel feels sticky or hard to turn.

- You hear unusual noises while using it.

- It wobbles or feels loose.

Taking good care will help your machine run smoothly and last longer!

What signs show my automatic metal lathe handwheel needs maintenance?

You might notice sticky movement, unusual sounds, or a wobbly feel. These signs mean it’s time for a check-up!

Comparing Manual vs. Automatic Handwheels

Key differences in operation. Pros and cons of each type.Using a manual handwheel feels like a fun workout for your arms! You control every move, which can be satisfying. However, it can take a long time to finish projects. On the other hand, automatic handwheels are like having a robot buddy. They speed things up but might not let you have as much fun! Here’s a quick look at their differences:

| Type | Pros | Cons |

|---|---|---|

| Manual | Great for precision! | Can be tiring. |

| Automatic | Fast and efficient! | Less hands-on control. |

Both have their charm! Choose wisely based on your style and speed needs. Remember, while the manual might give you a great arm workout, the automatic could help you finish your projects faster—maybe even in time for snack breaks!

Real-world Applications of Automatic Metal Lathe Handwheels

Industries that commonly use them. Case studies highlighting efficiency gains.Automatic metal lathe handwheels are like superheroes in many industries. They help manufacturers, machinists, and even hobbyists create precise parts quickly. Just imagine how much time people save! In the automotive industry, these handwheels boost efficiency by up to 30%. That’s like getting an extra cookie when you thought you were done! Here’s a quick look at some industries:

| Industry | Application | Efficiency Gain |

|---|---|---|

| Automotive | Part fabrication | 30% |

| Aerospace | Component machining | 25% |

| Manufacturing | Tool production | 20% |

In aerospace, they ensure parts fit perfectly, reducing waste and mistakes. Efficient tools lead to smoother operations and happier workers. Just think, they can even help turn bad days into good ones with fewer hiccups!

Future Trends in Automatic Metal Lathe Technology

Innovations in handwheel design and functionality. Impact of automation on the metalworking industry.New designs for the handwheel in automatic metal lathes are changing how we work. These upgrades make it easier and smarter to control machines. Automation is making metalworking faster and safer. It allows for precise cuts and less waste. Here are some exciting trends:

- Smart handwheels that can adjust automatically.

- Ergonomic designs that are comfortable to use.

- Advanced sensors for improved accuracy.

With these changes, the future of metalworking looks bright. Machines are not only helping workers but are also improving overall productivity.

What innovations are shaping the automatic metal lathe handwheel design?

Innovations include user-friendly controls, enhanced materials for durability, and smart technology for better performance.

Conclusion

In conclusion, an automatic metal lathe handwheel makes your work easier and more precise. It helps control the lathe smoothly, improving your projects. If you’re interested in metalworking, consider trying one. It can boost your skills. We encourage you to explore tutorials or guides on using a lathe effectively. Hands-on practice will make you a better machinist!FAQs

What Are The Key Features And Specifications To Consider When Selecting An Automatic Metal Lathe Handwheel?When choosing an automatic metal lathe handwheel, you should consider its size and grip. A comfortable grip helps you control it better. You also want to check how easily it spins. Look for a handwheel that fits well with the metal lathe you have. Lastly, think about the materials used; a sturdy handwheel lasts longer.

How Does The Design Of An Automatic Metal Lathe Handwheel Impact Precision And Ease Of Use During Machining Operations?The design of an automatic metal lathe handwheel helps you control the tool better. A comfortable handwheel makes it easier for you to turn, which means you can make precise cuts. If the handwheel is too big or too small, it can be hard to use, and mistakes may happen. Good design means you can work quickly and accurately, making your projects easier.

What Advancements Have Been Made In The Technology Of Automatic Metal Lathe Handwheels In Recent Years?Recently, automatic metal lathe handwheels have gotten smarter and easier to use. They now have sensors that help you move them more precisely. You can even control them with buttons or touch screens. This makes it simpler for you to create your projects. Overall, these updates make working with metal better and faster!

How Do Different Types Of Materials Used In The Construction Of Automatic Metal Lathe Handwheels Affect Their Performance And Durability?Different materials for handwheels can change how well they work and how long they last. For example, metal handwheels are strong and can handle heavy use. Plastic handwheels are light but might break more easily. If you choose the right material, your handwheel will work better and last longer.

What Maintenance Practices Are Recommended To Ensure The Longevity And Optimal Performance Of An Automatic Metal Lathe Handwheel?To keep your automatic metal lathe handwheel working well, you should clean it regularly. Use a soft cloth to wipe off dirt and dust. Check for any loose parts and tighten them if needed. Lubricate the moving parts with oil to help them move smoothly. Finally, store your lathe in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features And Specifications To Consider When Selecting An Automatic Metal Lathe Handwheel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing an automatic metal lathe handwheel, you should consider its size and grip. A comfortable grip helps you control it better. You also want to check how easily it spins. Look for a handwheel that fits well with the metal lathe you have. Lastly, think about the materials used; a sturdy handwheel lasts longer.”}},{“@type”: “Question”,”name”: “How Does The Design Of An Automatic Metal Lathe Handwheel Impact Precision And Ease Of Use During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of an automatic metal lathe handwheel helps you control the tool better. A comfortable handwheel makes it easier for you to turn, which means you can make precise cuts. If the handwheel is too big or too small, it can be hard to use, and mistakes may happen. Good design means you can work quickly and accurately, making your projects easier.”}},{“@type”: “Question”,”name”: “What Advancements Have Been Made In The Technology Of Automatic Metal Lathe Handwheels In Recent Years? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Recently, automatic metal lathe handwheels have gotten smarter and easier to use. They now have sensors that help you move them more precisely. You can even control them with buttons or touch screens. This makes it simpler for you to create your projects. Overall, these updates make working with metal better and faster!”}},{“@type”: “Question”,”name”: “How Do Different Types Of Materials Used In The Construction Of Automatic Metal Lathe Handwheels Affect Their Performance And Durability? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials for handwheels can change how well they work and how long they last. For example, metal handwheels are strong and can handle heavy use. Plastic handwheels are light but might break more easily. If you choose the right material, your handwheel will work better and last longer.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended To Ensure The Longevity And Optimal Performance Of An Automatic Metal Lathe Handwheel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your automatic metal lathe handwheel working well, you should clean it regularly. Use a soft cloth to wipe off dirt and dust. Check for any loose parts and tighten them if needed. Lubricate the moving parts with oil to help them move smoothly. Finally, store your lathe in a dry place to prevent rust.”}}]}