Have you ever watched a metal lathe in action? It’s like a dance of metal and machines, shaping pieces with precision. Now, imagine doing that with an automatic metal lathe. It makes everything faster and easier!

But there’s one thing we often forget—having the right stand for your lathe. A sturdy stand keeps your machine steady. It helps you focus on your work instead of worrying about wobbling. Why is that so important?

Without a solid stand, your projects can go wrong. A little shake can lead to big mistakes. Think about it: would you want a shaky table while writing a story? Of course not!

In this article, we will explore the world of automatic metal lathe stands. You will discover how to choose the best one for your lathe. Get ready to make your metalworking adventures smoother and more fun!

Automatic Metal Lathe Stand: Essential Features And Benefits

Exploring the Automatic Metal Lathe Stand

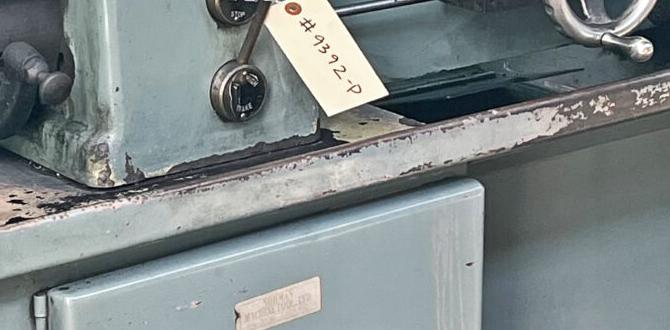

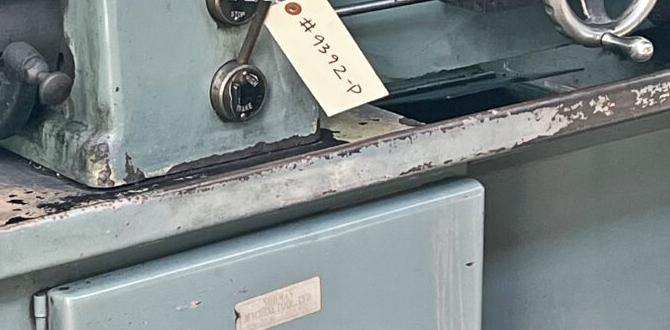

An automatic metal lathe stand is essential for any workshop. This sturdy base holds lathe machines firmly, making your work safer and more efficient. Did you know that a stable metal lathe stand can improve precision while cutting? It helps reduce vibrations, letting you create smooth pieces. Choosing the right stand also supports different lathe sizes and weights. By investing in a durable stand, you’ll enhance your machining experience and boost productivity. Isn’t that exciting?Understanding the Importance of a Metal Lathe Stand

Discuss the role of a sturdy stand in enhancing lathe performance.. Explain how a proper stand contributes to safety and precision in machining..A strong metal lathe stand plays a key role in how well the lathe works. It keeps the lathe steady and reduces vibrations during operation. This steadiness is essential for precision machining. If the lathe rocks, it can ruin your work. A sturdy stand also improves safety. A stable base helps prevent accidents, keeping the user safe. In short, a good lathe stand boosts performance and ensures accuracy.

How does a proper stand improve safety and precision?

A proper stand keeps the lathe stable and secure. This reduces the chance of mistakes and accidents. A well-designed stand ensures that the machine operates smoothly, allowing for better cuts and finishes.

Benefits of a sturdy lathe stand:

- Increased stability

- Improved safety

- Enhanced precision

- Reduced vibrations

Essential Features to Look for in a Metal Lathe Stand

Weight capacity and its impact on stability.. Vibration dampening and surface area considerations..Choosing the right stand for your lathe is important. First, consider the weight capacity. A stand with a higher capacity will be more stable. This prevents wobbling during use. Next, look for vibration dampening features. These help absorb shakes that can disturb your work. Lastly, check the surface area. A larger area provides more support and stability. The right stand makes every project easier and safer.

Why is weight capacity important for a lathe stand?

A strong weight capacity ensures that your lathe remains steady, reducing the risk of accidents and improving precision.

Features to check for stability:

- High weight capacity for stability

- Vibration-dampening materials

- Large surface area for support

Tools and Materials Needed for Building a Metal Lathe Stand

List of essential hand tools and power tools.. Recommended materials for durability and costeffectiveness..Building a sturdy metal lathe stand requires some essential tools and materials. You can tackle the project like a pro with a few hand tools and power tools. Key tools include a wrench set, a drill, a screwdriver, and a saw. Why not throw in a hammer for good measure? As for materials, wood and metal sheets are cost-effective and durable choices. Here’s a quick look:

| Tools | Materials |

|---|---|

| Wrench Set | Wood |

| Drill | Metal Sheets |

| Screwdriver | Bolts |

| Saw | Paint (optional) |

| Hammer | ^^ |

With these handy tools and materials, you’ll have your stand ready in no time! You may not become a superhero, but your lathe will surely stand tall and strong.

Step-by-Step Instructions for Constructing Your Metal Lathe Stand

Detailed instructions for measuring and cutting materials.. Assembly process and tips for ensuring alignment and stability..Creating your metal lathe stand is easier than it sounds! First, gather your materials and measure twice. A wise person once said, “Measure once, cut twice!”—wait, that’s not right! Aim for precision, and cut your wood or metal according to your measurements.

Next, assemble the pieces. Use a level to ensure everything lines up. If it feels wobbly, it probably is. Add some braces for extra support. Think of them as safety belts for your stand.

| Step | Action |

|---|---|

| 1 | Measure your materials carefully. |

| 2 | Cut the pieces based on your measurements. |

| 3 | Assemble the pieces while checking for alignment. |

| 4 | Add braces for stability. |

With patience and a bit of humor, your stand will be sturdy and ready for action!

Common Mistakes to Avoid When Building a Metal Lathe Stand

Highlight typical errors that can compromise safety and functionality.. Tips for avoiding pitfalls in design and construction..Building a metal lathe stand can be fun, but errors can turn it into a mess. One common mistake is skipping measurements. If your stand isn’t level, your lathe will dance like it’s at a party. Always double-check dimensions before cutting! Another error is using weak materials. A strong stand is a happy stand, and safety comes first. For tips, consider this table:

| Error | Solution |

|---|---|

| Incorrect measurements | Measure twice, cut once! |

| Weak materials | Use sturdy wood or metal. |

| Poor stability | Ensure a solid base. |

Following these tips can help avoid pitfalls and keep your workspace safe. Remember, a happy lathe stand means happy projects!

Maintenance Tips for Your Automatic Metal Lathe Stand

Best practices for ensuring longevity of the stand.. Routine inspections for stability and wear..Your automatic metal lathe stand deserves some love! First, check it regularly for any loose screws and wobbles. A stable stand stops tools from playing the tango and keeps everything in line. Keep it clean, too; dust looks great on a shelf, but not on your machinery. Lubricate moving parts often; they need their oil to run smoothly. A happy stand makes for fabulous creations! Need a quick reference? Here’s a handy table:

| Maintenance Task | Frequency |

|---|---|

| Routine Inspections | Weekly |

| Cleaning | Monthly |

| Lubrication | Every 3 months |

Following these tips ensures your stand will be the strong and reliable partner in your metalworking adventures!

Upgrading Your Metal Lathe Stand for Enhanced Functionality

Suggestions for addons like tool storage or mobility options.. Modifications for different machining projects and workflows..Upgrading your metal lathe stand can make your projects more fun and productive. Adding tool storage keeps everything handy, so you won’t spend time searching for that one elusive wrench. Mobility options help you move your lathe around like a dance partner, making it easier to adjust your workspace. Consider using modifications for specific machining projects. Tailoring your stand to your workflow is like giving it a cool outfit. Remember, a well-organized workspace is a happy workspace!

| Addon | Benefit |

|---|---|

| Tool Storage | Keeps tools handy and organized |

| Mobility Wheels | Easy to move for various projects |

| Height Adjustment | Comfortable for different users |

Frequently Asked Questions about Automatic Metal Lathe Stands

Address common queries about usage, maintenance, and customization.. Provide expert insights and tips based on industry standards..Have questions about your automatic metal lathe stand? You’re not alone! Users often ask about how to operate these handy machines. Remember, always start slow to avoid any mistakes. Maintenance is crucial too; don’t forget to clean the parts regularly! Customization can make your lathe stand unique. Want to add a touch of flair? Why not paint it your favorite color? Here are some quick FAQs:

| Question | Answer |

|---|---|

| How often should I maintain my lathe? | Every few months or whenever you spot dust! |

| Can I customize my lathe? | Absolutely! Get creative! |

| Is it easy to use? | Yes, with a little practice, you’ll be a pro! |

Keep these tips in mind, and your lathe stand will serve you well. Happy turning!

Conclusion

In conclusion, an automatic metal lathe stand supports your lathe and improves stability. It helps you work safely and efficiently. Choosing the right stand enhances your project results. Remember to consider size and material for durability. We encourage you to explore different stands and see which fits your needs best. Happy crafting and keep learning!FAQs

What Are The Key Features To Consider When Selecting An Automatic Metal Lathe Stand For A Workshop?When choosing a stand for an automatic metal lathe, you should think about a few important things. First, make sure the stand is strong and stable so it won’t tip over. Next, check if it fits your lathe size and weight. You should also look for adjustable height options, so you can work comfortably. Finally, think about storage space for tools and materials.

How Does The Design Of An Automatic Metal Lathe Stand Impact The Machining Process And Overall Precision?The design of an automatic metal lathe stand helps keep the machine stable. When it’s steady, the tool cuts better. This stability means we get more accurate shapes and sizes. A good stand makes sure everything stays in the right place during the machining process. This way, we can make parts that fit perfectly together.

What Materials Are Commonly Used To Construct Automatic Metal Lathe Stands, And What Are Their Advantages?Automatic metal lathe stands are usually made from steel or cast iron. Steel is strong and can hold heavy machines, making it stable. Cast iron also offers good weight and helps reduce vibrations. Both materials last a long time, so you won’t need to replace them often.

How Can The Stability And Vibration Dampening Of An Automatic Metal Lathe Stand Affect The Quality Of The Finished Workpieces?The stand of an automatic metal lathe needs to be stable to work well. If it shakes or rocks, it can make the pieces we create less accurate. This means the parts might not fit together correctly. By keeping the lathe steady, we can make better-quality workpieces. It’s like using a steady hand to draw a straight line!

What Are The Benefits Of Incorporating Adjustable Height Or Mobility Features Into An Automatic Metal Lathe Stand?Adjustable height helps you work comfortably, no matter how tall you are. If the stand moves easily, you can place it where you need it. This makes it simple to reach tools and materials. You can switch tasks quickly, which saves time and helps you finish your projects. These features make working with a metal lathe easier and more fun!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting An Automatic Metal Lathe Stand For A Workshop? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a stand for an automatic metal lathe, you should think about a few important things. First, make sure the stand is strong and stable so it won’t tip over. Next, check if it fits your lathe size and weight. You should also look for adjustable height options, so you can work comfortably. Finally, think about storage space for tools and materials.”}},{“@type”: “Question”,”name”: “How Does The Design Of An Automatic Metal Lathe Stand Impact The Machining Process And Overall Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of an automatic metal lathe stand helps keep the machine stable. When it’s steady, the tool cuts better. This stability means we get more accurate shapes and sizes. A good stand makes sure everything stays in the right place during the machining process. This way, we can make parts that fit perfectly together.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Construct Automatic Metal Lathe Stands, And What Are Their Advantages? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automatic metal lathe stands are usually made from steel or cast iron. Steel is strong and can hold heavy machines, making it stable. Cast iron also offers good weight and helps reduce vibrations. Both materials last a long time, so you won’t need to replace them often.”}},{“@type”: “Question”,”name”: “How Can The Stability And Vibration Dampening Of An Automatic Metal Lathe Stand Affect The Quality Of The Finished Workpieces? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The stand of an automatic metal lathe needs to be stable to work well. If it shakes or rocks, it can make the pieces we create less accurate. This means the parts might not fit together correctly. By keeping the lathe steady, we can make better-quality workpieces. It’s like using a steady hand to draw a straight line!”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Incorporating Adjustable Height Or Mobility Features Into An Automatic Metal Lathe Stand? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjustable height helps you work comfortably, no matter how tall you are. If the stand moves easily, you can place it where you need it. This makes it simple to reach tools and materials. You can switch tasks quickly, which saves time and helps you finish your projects. These features make working with a metal lathe easier and more fun!”}}]}