Have you ever wondered how metal pieces get their perfect threads? It’s a surprising process that many people overlook. The answer lies in the world of automatic metal lathes and their threading dials.

Imagine a machine that can create threads with incredible precision. That’s what an automatic metal lathe does! It uses a threading dial to help guide the cutting tool smoothly over the metal. But how does it work?

Here’s a fun fact: threading dials have been around for over a century! They combine clever design with advanced technology. This amazing tool helps both beginners and experts make strong, threaded metal pieces.

In this article, we will explore how an automatic metal lathe threading dial can make metalworking easier and more efficient. You might be surprised by what you learn!

Exploring The Benefits Of An Automatic Metal Lathe Threading Dial

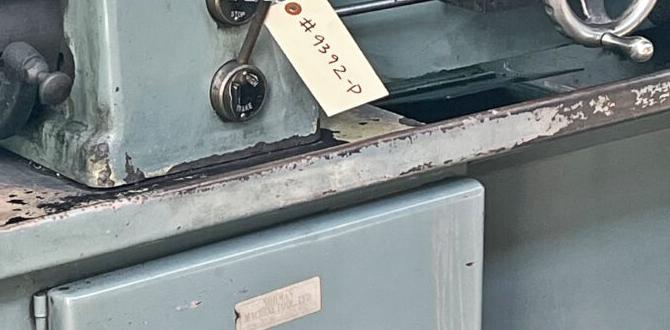

Automatic Metal Lathe Threading Dial

Discover how the automatic metal lathe threading dial simplifies your metalworking tasks. This tool makes it easy to create precise threads on various materials. Imagine being able to produce consistent and accurate threads without tedious manual adjustments. You can work faster and avoid mistakes. Did you know that using a threading dial can improve your productivity? It’s an essential tool for hobbyists and professionals alike. Experience the benefits of this advanced technology in your projects.What is an Automatic Metal Lathe Threading Dial?

Definition and purpose of a threading dial. Differences between manual and automatic threading dials.An automatic metal lathe threading dial helps create precise threads on metal parts. This tool makes threading easier and saves time. It automatically adjusts, unlike manual dials that need hand adjustments. With a manual dial, you must turn a knob to set the thread depth, which can take longer. The automatic dial does this for you!

What is the purpose of a threading dial?

In a lathe, the threading dial ensures perfect measurements. It helps tool users create accurate threads.

Key Differences:

- Manual Dial: Requires user adjustments.

- Automatic Dial: Adjusts automatically for accuracy.

Key Features of Automatic Metal Lathe Threading Dials

Common components and their functions. Technology advancements in modern threading dials.Automatic metal lathe threading dials have important parts that help them work well. Key components include the dial, gear mechanisms, and a digital display. The dial helps users set the threading accurately. Gear mechanisms control the movement, while the display shows the settings clearly.

Modern threading dials now feature advanced technology like digital readouts and automatic adjustments. These upgrades make threading easier and faster. With less guesswork, users can achieve precise results every time.

What components are in threading dials?

Common parts include:

- Dial: For setting measurements.

- Gear: Moves the lathe.

- Display: Shows the settings.

Benefits of Using an Automatic Threading Dial

Accuracy and precision in threading operations. Increased efficiency and productivity in metalworking.Using an automatic threading dial can be a game changer for metalworkers! With it, you get accuracy in your threading operations. That means fewer mistakes and more beautiful parts. Plus, it boosts efficiency—your projects get done faster, leaving more time for coffee breaks or, you know, admiring your work. Think of it this way: you’ll be threading like a pro without sweating like one!

| Benefit | Details |

|---|---|

| Accuracy | Reduces errors in threading. |

| Efficiency | Speeds up production time. |

How to Use an Automatic Metal Lathe Threading Dial

Stepbystep guide on setup and operation. Tips for maximizing performance.Using an automatic metal lathe threading dial is easier than tying your shoelaces—well, a bit more complicated. First, ensure your machine is plugged in and ready. Next, adjust the threading dial to the desired setting. Always check the speed; too fast is like a toddler with candy. For better results, keep your tools sharp and clean. It’s like brushing your teeth—nobody wants a dull experience.

| Step | Description |

|---|---|

| 1 | Plug in and turn on your machine. |

| 2 | Set the threading dial to your desired setting. |

| 3 | Check and adjust the speed. |

| 4 | Use sharp and clean tools. |

For the best performance, steady hands are key. Any shake and your thread could be as twisty as a curly fry! Remember to practice makes perfect, even in threading. Now go out there and show that lathe who’s boss!

Common Challenges and Solutions

Common issues faced when using threading dials. Troubleshooting tips and maintenance practices.Using an automatic metal lathe threading dial can sometimes feel like wrestling a slippery fish. One common issue is inaccurate threading. This can happen if the dial is misaligned or worn out. Another problem is skipping measurements, which can ruin your work faster than an out-of-tune guitar at a concert!

To tackle these, regular maintenance is key. Check the dial for debris and lubricate moving parts. If problems persist, recalibrating might save the day. Below is a simple table with tips:

| Issue | Solution |

|---|---|

| Inaccurate threading | Realign and check for wear |

| Skipped measurements | Clean and lubricate parts |

| Sticking dial | Recalibrate the dial |

Keep your lathe happy, and it’ll work like a charm! Remember, a well-cared lathe is a happy lathe!

Applications of Automatic Threading Dials in Various Industries

Review of industries that benefit from threading dials. Case studies of successful implementations.Many industries use automatic threading dials to improve their work. These dials help machines create threaded parts quickly and accurately. Here are some of the industries that benefit:

- Manufacturing: Saves time in making parts.

- Automotive: Creates precise threads for car components.

- Aerospace: Ensures safety in aircraft parts.

- Construction: Provides strong threaded materials for buildings.

Successful examples show their importance. For instance, a car factory cut production time by 30% using these dials. This led to faster delivery and happy customers. Companies that use automatic threading dials often see great results.

What industries benefit from threading dials?

Manufacturing, automotive, aerospace, and construction are major industries that gain efficiency from using automatic threading dials.

Future Trends in Automatic Metal Lathe Technology

Innovations on the horizon for threading dials. Potential impact of automation and AI on threading operations.New technology is changing how we use automatic metal lathe threading dials. Innovations are on the way. We may see smart dials that learn from each cut. These dials adjust settings by themselves. Imagine less manual work! Automation and AI will speed up threading tasks. Machines might minimize errors, leading to better quality parts. This change can save time and money in factories.

What innovations are happening with threading dials?

New smart features might allow dials to adapt automatically. Better data analysis can help operators choose the best settings.

Potential AI impacts:

- Fewer mistakes

- Faster operations

- Higher accuracy

- Less waste

The future looks bright for these machines. Exciting changes can help workers focus on important tasks. We are getting closer to fully automated factories!

Conclusion

In conclusion, the automatic metal lathe threading dial makes your work easier and more precise. It helps create threads quickly and accurately. We can see its importance in various projects. Now that you know about it, consider checking out tutorials or guides to learn how to use it. Practice makes perfect, so get started on your next project!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Threading Dials:An automatic metal lathe threading dial helps you make threads on metal pieces. You see numbers on the dial that tell you how far to move your tool. To use it, you watch the numbers closely. This helps you make precise cuts every time. It’s handy for making screws and bolts!

Sure! Please ask your question, and I’ll be happy to help you with a clear and simple answer.

What Is The Primary Function Of A Threading Dial On An Automatic Metal Lathe?The threading dial helps you make threads, which are the spiral grooves on screws and pipe parts. When you want to create these threads, you line up the dial with the right spot on your work. This way, you get perfect threads every time. It makes your work easier and more accurate!

How Does The Threading Dial Assist In Achieving Precise Thread Depth And Pitch During Machining?The threading dial helps you get the right thread depth and pitch when machining. It shows you exactly when to move the tool for each turn. By following the dial’s numbers, you can make sure the threads are even. This makes your work look better and work correctly. Using the threading dial is like following a map to get to a treasure!

What Are The Differences Between A Mechanical Threading Dial And An Electronic Threading System On Modern Lathes?A mechanical threading dial helps you manually line up the tool for cutting threads. You turn a knob and watch the dial closely. An electronic threading system uses buttons and a screen to do this for you. It’s easier and faster, so you don’t have to measure as much. Overall, the electronic system is more modern and can be more accurate.

How Do You Properly Calibrate A Threading Dial For Accurate Threading Operations?To calibrate a threading dial, you first need to set your tool to the beginning of a thread. Turn the dial until you see zero. Then, move the tool to touch the part you’re threading. Finally, turn the dial to make sure you can start threading at the correct spot. This helps you make accurate threads every time!

What Common Issues Can Arise With Threading Dials During Operation, And How Can They Be Resolved?When using threading dials, you might see some common problems. The dial can stick or not move smoothly. You can fix this by cleaning it or adding a little oil. Sometimes, the dial could be misaligned, which you can fix by adjusting its position. Always check that everything is tight and secure before you start working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Automatic Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “An automatic metal lathe threading dial helps you make threads on metal pieces. You see numbers on the dial that tell you how far to move your tool. To use it, you watch the numbers closely. This helps you make precise cuts every time. It’s handy for making screws and bolts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a clear and simple answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Threading Dial On An Automatic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you make threads, which are the spiral grooves on screws and pipe parts. When you want to create these threads, you line up the dial with the right spot on your work. This way, you get perfect threads every time. It makes your work easier and more accurate!”}},{“@type”: “Question”,”name”: “How Does The Threading Dial Assist In Achieving Precise Thread Depth And Pitch During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you get the right thread depth and pitch when machining. It shows you exactly when to move the tool for each turn. By following the dial’s numbers, you can make sure the threads are even. This makes your work look better and work correctly. Using the threading dial is like following a map to get to a treasure!”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Mechanical Threading Dial And An Electronic Threading System On Modern Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A mechanical threading dial helps you manually line up the tool for cutting threads. You turn a knob and watch the dial closely. An electronic threading system uses buttons and a screen to do this for you. It’s easier and faster, so you don’t have to measure as much. Overall, the electronic system is more modern and can be more accurate.”}},{“@type”: “Question”,”name”: “How Do You Properly Calibrate A Threading Dial For Accurate Threading Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate a threading dial, you first need to set your tool to the beginning of a thread. Turn the dial until you see zero. Then, move the tool to touch the part you’re threading. Finally, turn the dial to make sure you can start threading at the correct spot. This helps you make accurate threads every time!”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise With Threading Dials During Operation, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using threading dials, you might see some common problems. The dial can stick or not move smoothly. You can fix this by cleaning it or adding a little oil. Sometimes, the dial could be misaligned, which you can fix by adjusting its position. Always check that everything is tight and secure before you start working.”}}]}