Have you ever wondered how metal parts are made so perfectly? Automatic metal lathe tools are the secret behind that! These machines can shape metal faster and more accurately than a human can. Imagine walking into a workshop and seeing one of these machines spinning to create a beautiful, smooth piece of metal. It’s like watching magic happen!

These tools don’t just work by themselves. They follow special programs that tell them what to do. This means they can make many pieces, all the same, in a short time. Isn’t that amazing? With automatic metal lathe tools, even the most detailed designs become easy to produce.

People use these machines in many places. Factories, home workshops, and schools all benefit from their power. Are you curious about how these machines work? Let’s dive deeper into the fascinating world of automatic metal lathe tools!

Discover The Benefits Of Automatic Metal Lathe Tools

Automatic Metal Lathe Tools

Automatic metal lathe tools are amazing machines that shape metal with precision. Have you ever wondered how complex metal parts are made? These tools automatically spin and cut metal into desired shapes, saving time and effort. They are ideal for busy workshops and can produce consistent results quickly. Plus, they reduce the need for manual labor. Imagine creating intricate designs without much hassle! These tools truly boost productivity and bring creativity to metalworking.What are Automatic Metal Lathe Tools?

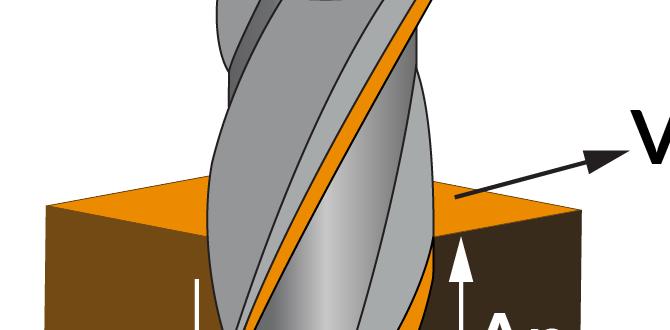

Definition and explanation of automatic metal lathe tools. Key components and features that distinguish them from manual lathes.Automatic metal lathe tools are machines that shape metal into different forms. They work faster and more accurately than manual lathes. This makes them useful in factories for mass production. Key features include:

- Automated controls for easy operation.

- High precision for detailed work.

- Ability to perform multiple tasks without stopping.

These features make automatic lathes popular for producing parts in various industries, from cars to electronics.

What do automatic metal lathe tools do?

They efficiently cut metal into precise shapes while saving time and reducing waste.

Benefits of Using Automatic Metal Lathe Tools

Increased efficiency and productivity in metalworking. Enhanced precision and consistency in manufacturing processes.Using automatic metal lathe tools can make metalworking a breeze! These machines boost efficiency, meaning you get more done in less time. Imagine turning out parts faster than your friend can eat a pizza! Plus, they provide precision that is spot-on every time. No more wobbly bits or uneven edges—just perfect shapes, every single cut. It’s like having a magician in your workshop, making your projects fly off the lathe!

| Benefits | Description |

|---|---|

| Increased Efficiency | Get more work done quickly. |

| Enhanced Precision | Perfect cuts every time! |

Applications of Automatic Metal Lathe Tools

Industries that benefit from using automatic lathes. Examples of specific projects and components manufactured.Many industries benefit from automatic metal lathe tools. These machines make it easy to create precise parts quickly. Here are some examples:

- Automotive Industry: Parts like engine blocks and gears are often made with these lathes.

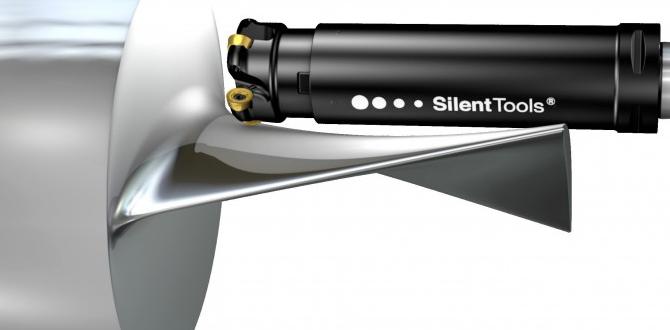

- Aerospace: Components like fuselage frames and engine mounts require high precision.

- Electronics: Items like casings for smartphones or circuits can be produced efficiently.

Each project shows how versatile these tools are. They help make important items we use every day. This leads to better products and faster production times.

What industries use automatic metal lathes?

Many industries use automatic metal lathes. The most common ones are automotive, aerospace, and electronics. Each relies on these machines for creating precise parts that improve quality and performance.

Factors to Consider When Choosing an Automatic Metal Lathe Tool

Key specifications to assess (size, speed, capabilities). Importance of brand reputation and warranty options.Choosing the right machine can feel like picking a favorite pizza topping—everyone has an opinion! First, assess key specifications like size, speed, and capabilities. A lathe that’s too small can be as frustrating as a friend who won’t share! Also, consider the brand’s reputation; a reliable name can save you grief later. Warranty options are vital too. A good warranty is like a safety net. It catches you when things go wrong—preferably not during your pizza party!

| Specification | Importance |

|---|---|

| Size | Fits your workspace |

| Speed | Affects production time |

| Capabilities | Determines what you can create |

| Brand Reputation | Trustworthy brands = Less hassle |

| Warranty Options | Protects your investment |

Maintenance and Care for Automatic Metal Lathe Tools

Routine maintenance practices to extend tool life. Signs of wear and troubleshooting common issues.Taking care of automatic metal lathe tools helps them last longer. Regular cleaning is a must. Dirt can cause problems. Check for loose parts and tighten them regularly. Keep tools lubricated for smooth operation. This helps prevent wear and tear. Watch for signs like unusual noises or poor cuts. These can mean it’s time for repairs. Addressing issues quickly can save time and money.

What are some signs of wear in automatic metal lathe tools?

Common signs include strange noises, vibrations, or uneven cuts.Routine Maintenance Tips:

- Clean regularly.

- Check for loose parts.

- Lubricate when needed.

- Inspect for wear and tear.

Future Trends in Automatic Metal Lathe Technology

Innovations and advancements shaping the future of automatic lathes. The role of AI and automation in metalworking processes.New technologies are changing the game for automatic metal lathes. Innovations like smart sensors help machines work faster and more accurately. Imagine a lathe that can think! This is where AI and automation come in, making tasks easier and more efficient. Instead of workers getting tired, machines can work round the clock—kind of like superheroes in the workshop! Here’s a quick look at what’s on the horizon:

| Trend | Description |

|---|---|

| Smart Tools | Tools that learn and adapt to tasks. |

| Real-Time Monitoring | Systems that track performance on the go. |

| Eco-Friendly Solutions | Techniques that reduce waste and save energy. |

With these advancements, the future looks bright and shiny, just like polished metal!

Resources for Learning and Mastering Automatic Metal Lathe Tools

Recommended books, online courses, and tutorials. Communities and forums for networking and support.If you want to become a metal lathe whiz, there are plenty of resources to help you out. Check out popular books that cover basic to advanced techniques. Websites like Coursera and Udemy offer online courses on lathe operation. YouTube is a treasure trove of helpful tutorials. Don’t forget to join communities and forums like Reddit’s r/Machinists. It’s the perfect place to ask questions and share funny metal lathe stories. Who knew lathes could bring people together?

| Resource Type | Recommended Resource |

|---|---|

| Books | “Metal Lathe for Beginners” by Mike Smith |

| Online Course | Coursera’s “Intro to Lathe Work” |

| Tutorials | YouTube – “Lathe Tips & Tricks” |

| Community | Reddit’s r/Machinists |

Conclusion

In conclusion, automatic metal lathe tools help us create precise metal parts easily. They save time and improve our work quality. You can find many types of these tools for different projects. Explore more about their features and choose one that fits your needs. Start your journey into metalworking, and see how these tools can enhance your skills!FAQs

Sure! Here Are Five Questions Related To Automatic Metal Lathe Tools:Sure! Here are five questions about automatic metal lathe tools: 1. **What does an automatic metal lathe do?** An automatic metal lathe shapes metal. It spins the metal while cutting tools carve it into the right shape. 2. **How does it work?** We place a metal piece in the lathe. It spins, and tools move to cut and shape it. 3. **What materials can we use with it?** You can use different metals like aluminum, steel, and brass. These metals can be shaped easily. 4. **Is it safe to use?** Yes, but we must follow safety rules. Always wear safety gear and be careful around moving parts. 5. **Why is it important?** Automatic metal lathes help make precise parts quickly. This makes building machines and tools much easier.

Sure! Just ask your question, and I’ll be happy to help you with a simple answer.

What Are The Primary Advantages Of Using Automatic Metal Lathe Tools Over Manual Lathes In Precision Machining?Automatic metal lathes are much faster than manual lathes. They can make precise pieces without needing much help from a person. This means you get more parts done in less time. Also, automatic lathes are great at keeping everything the same, which helps avoid mistakes. This makes your work more accurate and saves you time.

How Do Cnc (Computer Numerical Control) Automatic Metal Lathes Improve Efficiency And Accuracy In Production Processes?CNC automatic metal lathes are machines that help us make metal parts quickly and accurately. They use a computer to control how the machine works. This means we can make many pieces that are all the same size. Because they follow precise instructions, mistakes are less likely. This saves time and makes products better!

What Types Of Materials Can Be Effectively Machined Using Automatic Metal Lathe Tools, And What Considerations Should Be Taken Into Account?You can use automatic metal lathe tools to machine materials like soft metals, wood, and some plastics. These tools work best with materials that can be easily shaped. We should consider how hard the material is and the safety rules when using the lathe. It’s also important to check the tool’s settings for each material. That way, we make sure everything runs smoothly and safely.

What Are The Key Features To Look For When Selecting An Automatic Metal Lathe Tool For A Specific Manufacturing Application?When choosing an automatic metal lathe tool, look for important features. First, check its size to fit your workspace. Next, see how easy it is to use and control. You also want a tool that can handle different types of metal. Lastly, make sure it has good safety features to protect you while you work.

How Has The Technology And Design Of Automatic Metal Lathe Tools Evolved In Recent Years To Meet Industry Demands?Automatic metal lathe tools have changed a lot recently. They now use smart computer controls for better precision. This means they can make parts faster and more accurately. New materials also make the tools stronger and last longer. These changes help factories keep up with the demand for high-quality products.