Have you ever wondered how complex shapes are made in metalworking? One essential tool for this task is the ball nose end mill. This tool looks like a small ball attached to a stick. It helps create rounded shapes and smooth finishes on different materials.

Ball nose end mills are popular in many industries. They can make everything from intricate designs on car parts to unique details in sculptures. Imagine a sculptor using this tool to carve a beautiful statue. It shows just how versatile this tool can be.

Did you know that ball nose end mills can also help in 3D printing? They make sure that parts fit together perfectly. This tool helps craftsmen and hobbyists achieve great results. Isn’t it amazing how one tool can have so many uses?

In this article, you will discover various applications of ball nose end mills. You’ll learn why they are a favorite among professionals and DIY enthusiasts alike. Get ready to explore the impressive world of manufacturing and design!

Ball Nose End Mill Applications: Enhancing Precision Cutting

Ball nose end mills are versatile tools used in various machining tasks. They excel at creating curved surfaces and intricate designs. This makes them ideal for 3D contouring and sculpting, often seen in industries like aerospace and automotive. Did you know they can even help create complex models for prototyping? Users appreciate their ability to produce smooth finishes. Exploring the right cutting speed and feed rates enhances performance, making it easier to achieve precise results.

Understanding Ball Nose End Mills

Definition and features of ball nose end mills. Comparison with other types of end mills.

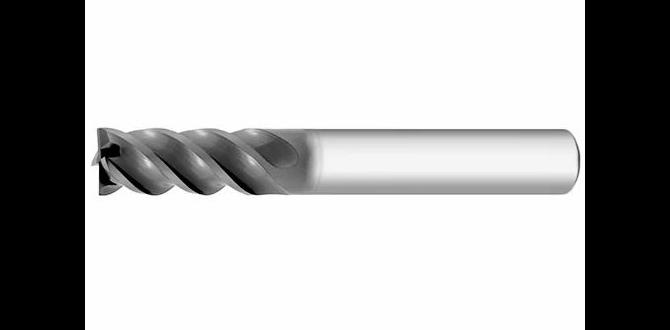

A ball nose end mill is a tool with a rounded tip. This shape helps it create smooth curves and detailed shapes in materials like metal, wood, or plastic. Ball nose end mills are special because they can reach into tight spots and make intricate designs. They differ from regular end mills, which have flat tips, by being better for 3D work.

- Creates curved surfaces: Ideal for 3D shapes

- Fine details: Great for intricate designs

- Versatile: Works on various materials

Regular end mills are better for straight cuts. They do not create the same smooth curves. Ball nose end mills are often chosen for special projects needing precise shapes. This makes them popular in both hobby and professional environments.

What material do ball nose end mills work with?

Ball nose end mills can work with many materials, including metal, wood, and plastic. This versatility makes them useful for a range of projects.

Common Applications of Ball Nose End Mills

3D contouring and shaping. Slotting and pocketing techniques.

Ball nose end mills are perfect for many tasks. They create smooth, curved shapes in materials. This helps in 3D contouring and shaping. They can make complex designs easily. Also, they are great for slotting and pocketing techniques. This means they can cut out spaces or grooves in metal or wood. Here are some uses:

- Sculpting three-dimensional models.

- Making molds for casting.

- Creating intricate patterns in materials.

These tools are essential in workshops and factories. They help in making everything from toys to car parts. Using them can improve the quality and detail of your work.

What are the main uses of ball nose end mills?

The main uses include 3D shaping and creating slots or pockets in materials. This makes them versatile for many projects.

Choosing the Right Ball Nose End Mill for Your Project

Factors to consider: diameter, length, and flute design. Matching end mill specifications to project requirements.

Choosing the right ball nose end mill can make a big difference in your project. Several factors matter, like diameter, length, and flute design. These traits help shape how well the tool cuts. It’s vital to match what your project needs with the end mill’s specs. Here are some key points to think about:

- Diameter: A larger diameter cuts wider paths.

- Length: Longer tools reach deeper areas easily.

- Flute Design: Fewer flutes can clear material faster.

By understanding these factors, you’ll select the best end mill for your task.

What should I consider when choosing a ball nose end mill?

Think about diameter, length, and flute design. These help make sure your mill fits your project. It’s essential to choose wisely for the best results!

Technical Advantages of Using Ball Nose End Mills

Improved surface finish and accuracy. Reduced risk of tool breakage and wear.

Using ball nose end mills offers several technical advantages. These tools help create a smoother surface finish and greater accuracy in machining. This means less sanding and better results! Additionally, they have a lower chance of breaking or wearing out. This reduces downtime and costs. Strong designs make them reliable for long jobs.

What are the benefits of ball nose end mills?

Ball nose end mills can improve surface quality and accuracy. They also minimize the risk of tool breakage and wear, making them a smart choice for various projects.

- Smoother finishes make products look better.

- Higher accuracy means less rework needed.

- Strong materials resist breakage, saving money.

Best Practices for Using Ball Nose End Mills

Optimal feed rates and speeds. Effective coolant usage and maintenance tips.

Using ball nose end mills effectively can greatly enhance your machining tasks. To achieve the best results, focus on these key points:

- Optimal feed rates and speeds: Try to match your feed rate to the material’s type. Generally, softer materials need faster speeds. Experiment to find the sweet spot for efficiency.

- Coolant usage: Proper coolant can prevent overheating. Use it generously to maintain the tool’s life. Clean the area to ensure the coolant effectively cools down your end mill.

Regular maintenance is crucial. Always check your tools for wear. A sharp ball nose end mill will cut better and last longer. Don’t forget to keep the work area clean for safety and accuracy!

How can I determine the right feed rates for ball nose end mills?

To find the right feed rates, consider the material and the diameter of the end mill. For better accuracy, use manufacturer recommendations as a guide.

Case Studies: Successful Utilization of Ball Nose End Mills

Realworld examples across various industries. Lessons learned and outcomes achieved.

Various industries have successfully embraced ball nose end mills, leading to impressive outcomes. For instance, in the automotive world, one company improved design precision by 25%. This was thanks to the curved shapes created using these tools. In the aerospace sector, a manufacturer reduced production time by 30% while ensuring safety standards. These success stories highlight important lessons, like how precision and efficiency can go hand in hand and help businesses soar to new heights!

| Industry | Outcome | Lessons Learned |

|---|---|---|

| Automotive | 25% design precision increase | Precision matters! |

| Aerospace | 30% reduced production time | Efficiency and safety can coexist. |

Future Trends in Ball Nose End Mill Technology

Innovations in design and manufacturing. The impact of automation and CNC technology on usage.

Exciting changes are coming to ball nose end mills! New designs are popping up like popcorn at a movie theater. Manufacturers are using advanced 3D printing and fancy materials to boost durability and performance. Plus, with automation and CNC technology, these tools are becoming smarter and faster. Think of it like a robot chef that cuts shapes perfectly every time! This means more accuracy, less waste, and a lot more fun in the workshop!

| Innovation | Impact |

|---|---|

| 3D Printing | Better designs and durability |

| Automation | Faster and accurate cuts |

| CNC Technology | Precision and less waste |

Conclusion

In summary, ball nose end mills are versatile tools for making curved shapes and smooth finishes in materials like metal and wood. They help create intricate designs and precise carvings. If you’re interested in machining or woodworking, consider exploring different types of end mills. You can enhance your skills and projects by learning how to use these tools effectively. Happy crafting!

FAQs

Certainly! Here Are Five Questions Related To The Applications Of Ball Nose End Mills:

Ball nose end mills are tools used in machines to shape materials. We can use them to make curved edges and smooth shapes. They help create parts like toys or car parts. You can find them in factories where they make precise designs. Using a ball nose end mill makes work easier and faster!

Sure, I can help with that! Just ask your question, and I’ll keep my answer simple and clear for you.

What Are The Primary Industrial Applications Of Ball Nose End Mills In Machining?

Ball nose end mills are special tools we use in machines to shape materials. We use them to make curved surfaces, like in molds and parts for cars. They help us create smooth and rounded edges. You can find them used in industries like making toys, airplanes, and even medical devices. These tools help us make products that fit together nicely.

How Does The Design Of A Ball Nose End Mill Affect Its Performance In Contouring And Milling Tasks?

The ball nose end mill has a rounded tip. This round shape helps us carve smooth curves and shapes in materials. It is great for contouring because it can reach into tight spots easily. When we use it, we get better finishes without sharp edges. So, its design helps us do our work more neatly and accurately.

In What Ways Do Material Selection And Coating Influence The Effectiveness Of Ball Nose End Mills In Specific Applications?

Choosing the right material for ball nose end mills makes them strong and long-lasting. Coatings help reduce friction and heat when they cut. This means they can work better and last longer in tough jobs. If we pick the best material and coating, our tools can cut more smoothly and accurately.

What Are The Advantages Of Using Ball Nose End Mills Over Flat End Mills For Achieving Complex Geometries In Cnc Machining?

Ball nose end mills are better for making complex shapes because they have a rounded tip. This shape helps create smooth curves and details that flat end mills can’t make as easily. When you use a ball nose end mill, you can get nice, rounded edges. This makes your project look better and more professional. Plus, it can save you time because it takes fewer steps to get those shapes right.

How Do Factors Like Feed Rate And Spindle Speed Impact The Quality Of Surface Finish When Using Ball Nose End Mills?

Feed rate is how fast you move the tool, and spindle speed is how fast the tool spins. If you go too fast, the surface might be rough. If you go too slow, it can cause extra heat and wear out the tool. Finding the right feed rate and spindle speed helps make a smooth finish. So, we need to balance these two steps for the best results.