Have you ever watched a metal lathe in action? It spins and shapes metal into amazing objects. But did you know that benchtop metal lathes can do even more with the right accessories? These tools can make your projects easier and more fun.

Imagine creating custom parts with precision. That’s the magic of a metal lathe, especially when you add the right accessories. They can help you cut, sand, and polish like a pro. Are you ready to dive into the world of metalworking?

In this article, we’ll explore some of the best benchtop metal lathe accessories available. Whether you are a beginner or an expert, these tools can take your work to the next level. So, let’s get started and discover how to maximize your lathe’s potential!

Essential Benchtop Metal Lathe Accessories For Precision Work

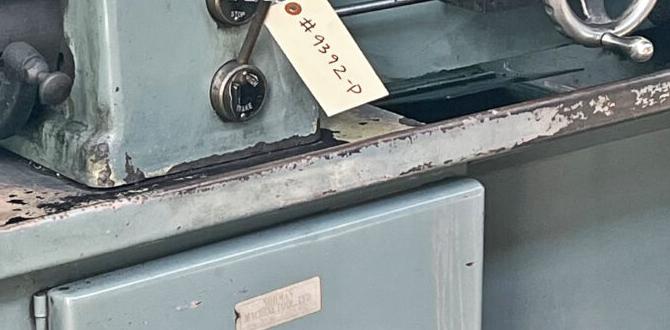

Benchtop Metal Lathe Accessories

Benchtop metal lathe accessories can greatly improve your projects. These items make turning metal easier and more accurate. Common accessories include tool holders, chucks, and faceplates. Using a steady rest can stabilize your work too. Have you ever struggled to hold a piece while working? Accessories like this solve that problem. They help you create professional-looking pieces at home, making your lathe work more enjoyable and effective. Investing in quality accessories can transform your crafting experience!Essential Accessories for Precision Machining

Importance of tailstock and steady rests for stability. Benefits of quickchange tool holders and their impact on efficiency.Having the right accessories can make all the difference in precision machining. A tailstock provides stability, keeping your workpiece firmly in place, while steady rests support long items that wobble like a dancing giraffe! These tools prevent unwanted vibrations, helping you achieve a smooth finish.

Don’t forget quick-change tool holders! They speed up your work, letting you switch tools as fast as a cheetah chasing its lunch. The time saved with these tools can make your projects much more efficient. Invest in these accessories to keep your lathe running like a dream!

| Accessory | Benefit |

|---|---|

| Tailstock | Increases stability |

| Steady Rest | Supports long workpieces |

| Quick-Change Tool Holder | Boosts efficiency |

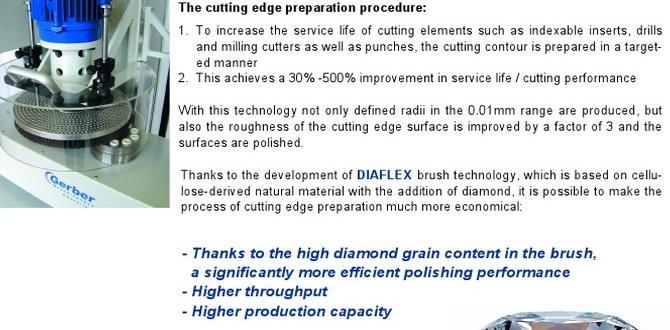

Cutting Tools for Versatile Operations

Types of cutting tools specifically designed for metal lathes. How to choose the right cutting tools based on materials.Many cutting tools are used for metal lathes. These tools help shape and cut metal precisely. Here are some common types:

- Turning tools

- Parting tools

- Boring tools

- Tapping tools

To choose the right tool, consider the metal type. Hard metals need tougher tools, while soft metals can use simpler ones. Always match the tool to the job for the best results!

What are the best cutting tools for different metals?

The best cutting tools depend on the metal used. For steel, use high-speed steel tools. For aluminum, carbide tools work well. Always check before starting!

Measurement and Alignment Tools

Role of calipers and micrometers in achieving precision. Importance of alignment tools for ensuring accuracy in machining.Calipers and micrometers are like your best buddies in the world of machining. They help you measure things down to tiny details, ensuring everything fits just right. Think of them as your personal measuring superheroes, saving the day by achieving that perfect precision!

Now, don’t forget about alignment tools! These nifty gadgets keep everything lined up like ducks in a row. Maintaining accuracy in machining is key. A slight misalignment can turn your smooth project into a wobbly masterpiece. Remember, a lathe out of line can make even the best piece feel like it’s dancing the cha-cha!

| Tool | Purpose |

|---|---|

| Calipers | Measure lengths and widths with ease! |

| Micrometers | Provide ultra-precise measurements. |

| Alignment tools | Ensure accuracy for smooth operation. |

Maintenance Accessories for Longevity

Importance of lubricants and cleaning tools in upkeep. Recommendations for tool storage solutions to prolong accessory lifespan.Keeping your tools in great shape is key for long-lasting use. Lubricants make moving parts smooth and prevent rust. They help machines run better. Cleaning tools regularly removes grime and dust. It keeps accessories clean and efficient.

For storage, use a dry, organized place. This protects tools from damage. Here are some ideas:

- Use a toolbox for small parts.

- Shelves can hold larger items.

- Hang tools on a wall to save space.

Why is regular maintenance important?

Regular maintenance keeps your tools working well and extends their life.

Choosing the Right Accessories for Your Needs

Factors to consider when selecting accessories for your specific projects. Comparison of budgetfriendly vs. highend accessory options.Picking the best accessories can make your projects easier and more fun. First, think about what you need for your tasks. Do you want items that save money or the best quality? Both choices have pros and cons. Take a look:

- Budget-friendly options: Great for beginners, they help you practice without spending too much.

- High-end options: These often last longer and offer better performance, but they cost more.

Remember, your choice depends on your skill level and project goals.

What should I consider when selecting accessories?

Think about materials and your budget. It’s important to match accessories with your project. Always consider compatibility with your lathe to avoid issues down the line.

Resources and Where to Buy

Recommended online retailers and local stores for purchasing accessories. Importance of reviews and ratings when choosing products.Finding the right place to buy accessories can feel like a treasure hunt. Luckily, online retailers like Amazon and eBay are popular choices, offering a wide range with a click of a button. Local stores like Home Depot or specialty shops may also have what you need. Always check reviews and ratings; they’re like a crystal ball, helping you see what works best. Remember, a *four-star* review might just mean, “I used it once and it was okay!”

| Retailer | Type |

|---|---|

| Amazon | Online |

| eBay | Online |

| Home Depot | Local |

| Specialty Stores | Local |

Keep this in mind: read those reviews! They guide you towards the best gear. You don’t want to end up with a dud, unless you like playing “guess what’s broken!”

Conclusion

In conclusion, benchtop metal lathe accessories enhance your machining projects. Key tools include tool holders, chucks, and cutting tools. They improve accuracy and efficiency. You can explore these accessories to upgrade your lathe experience. Consider reading more about each accessory to find what suits your needs best. Let’s dive deeper and make your projects even better!FAQs

Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Accessories:Benchtop metal lathe accessories help you work better and faster on your projects. These tools can include tool holders, chucks, and cutting tools. They make it easier to shape and cut metal pieces. You can find different accessories for different tasks. Using the right accessories can improve your work and make it more fun!

Sure! Please give me a question from the section you want me to answer.

What Essential Accessories Should Every Benchtop Metal Lathe Owner Have For Improved Functionality?Every benchtop metal lathe owner should have a few important tools. You need good cutting tools to shape the metal. A quality chuck helps hold the metal in place securely. You should also have a tool rest for better support while working. Finally, safety glasses keep your eyes safe from flying metal bits!

How Can A Steady Rest Enhance The Accuracy And Quality Of Turning Operations On A Benchtop Lathe?A steady rest helps keep the piece of metal or wood steady while we work on it. This means it won’t shake or wobble. When it’s stable, we can make better cuts and smoother shapes. It helps us make our projects look nicer and more precise. Using a steady rest can really improve our turning work!

What Types Of Chucks Are Compatible With Benchtop Metal Lathes, And How Do They Differ In Terms Of Performance?Benchtop metal lathes can use three types of chucks: ***3-jaw, 4-jaw, and collet chucks***. A **3-jaw chuck** holds round pieces tightly and is easy to use. A **4-jaw chuck** can hold square or odd-shaped items better, but it takes more time to set up. **Collet chucks** are great for small pieces and give you a precise grip. Each type helps you work with different shapes and sizes, affecting how well you can make your projects.

How Do Tool Holders And Quick-Change Systems Increase Efficiency In Machining Tasks On A Benchtop Metal Lathe?Tool holders and quick-change systems make it easier to switch tools on a benchtop metal lathe. This saves you time because you don’t have to stop and find a tool. You can change tools quickly and keep working. With these systems, your projects get done faster and you can do more in less time.

What Types Of Measuring Tools And Gauges Are Recommended For Use In Conjunction With Benchtop Metal Lathes To Ensure Precision?To make sure your work is precise on a benchtop metal lathe, you can use different measuring tools. A caliper helps you measure small parts accurately. A micrometer can be used for even finer measurements. A dial gauge checks if something is really straight or level. Using these will help you create better projects!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Benchtop Metal Lathe Accessories:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Benchtop metal lathe accessories help you work better and faster on your projects. These tools can include tool holders, chucks, and cutting tools. They make it easier to shape and cut metal pieces. You can find different accessories for different tasks. Using the right accessories can improve your work and make it more fun!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me a question from the section you want me to answer. “}},{“@type”: “Question”,”name”: “What Essential Accessories Should Every Benchtop Metal Lathe Owner Have For Improved Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Every benchtop metal lathe owner should have a few important tools. You need good cutting tools to shape the metal. A quality chuck helps hold the metal in place securely. You should also have a tool rest for better support while working. Finally, safety glasses keep your eyes safe from flying metal bits!”}},{“@type”: “Question”,”name”: “How Can A Steady Rest Enhance The Accuracy And Quality Of Turning Operations On A Benchtop Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A steady rest helps keep the piece of metal or wood steady while we work on it. This means it won’t shake or wobble. When it’s stable, we can make better cuts and smoother shapes. It helps us make our projects look nicer and more precise. Using a steady rest can really improve our turning work!”}},{“@type”: “Question”,”name”: “What Types Of Chucks Are Compatible With Benchtop Metal Lathes, And How Do They Differ In Terms Of Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Benchtop metal lathes can use three types of chucks: ***3-jaw, 4-jaw, and collet chucks***. A **3-jaw chuck** holds round pieces tightly and is easy to use. A **4-jaw chuck** can hold square or odd-shaped items better, but it takes more time to set up. **Collet chucks** are great for small pieces and give you a precise grip. Each type helps you work with different shapes and sizes, affecting how well you can make your projects.”}},{“@type”: “Question”,”name”: “How Do Tool Holders And Quick-Change Systems Increase Efficiency In Machining Tasks On A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tool holders and quick-change systems make it easier to switch tools on a benchtop metal lathe. This saves you time because you don’t have to stop and find a tool. You can change tools quickly and keep working. With these systems, your projects get done faster and you can do more in less time.”}},{“@type”: “Question”,”name”: “What Types Of Measuring Tools And Gauges Are Recommended For Use In Conjunction With Benchtop Metal Lathes To Ensure Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your work is precise on a benchtop metal lathe, you can use different measuring tools. A caliper helps you measure small parts accurately. A micrometer can be used for even finer measurements. A dial gauge checks if something is really straight or level. Using these will help you create better projects!”}}]}