Have you ever wondered how something as complicated as a machine is made? In the world of manufacturing, a benchtop metal lathe is a key tool. It can shape and cut metal with amazing precision. But how do designers create these tools? That’s where CAD design comes in!

Imagine you want to make a cool robot for a school project. You need the right tools to build it. A benchtop metal lathe can help you create those parts. Using CAD design, you can sketch and plan every detail before even touching any metal.

Did you know that the first lathes were made thousands of years ago? They were simple devices but laid the groundwork for today’s advanced tools. With modern technology, we now design metal lathes with great accuracy. This means you can build amazing things without the guesswork!

In this article, we’ll explore how CAD design transforms the world of benchtop metal lathes. Get ready to dive into the exciting process of bringing metal magic to life!

Benchtop Metal Lathe Cad Design: A Comprehensive Guide

Benchtop Metal Lathe CAD Design

Using a benchtop metal lathe for CAD design can be exciting and rewarding. Imagine crafting precise metal parts right at home! With the right techniques, you can create custom designs easily. Key points include understanding lathe operations, choosing suitable materials, and applying CAD software effectively. Did you know that these lathes can enhance creativity in your projects? They allow you to bring your unique ideas to life with precision and fun. Embrace the art of metalworking today!Understanding Benchtop Metal Lathes

Definition and uses of benchtop metal lathes. Advantages of using a benchtop metal lathe for small projects.Benchtop metal lathes are handy machines that spin metal to shape it. They help create parts for all sorts of projects. Imagine making tiny car parts or fun robot pieces! Their size makes them perfect for small workspaces. You can easily set one up on a workbench without needing a huge garage.

Using a benchtop metal lathe for small projects has many benefits. First, they are affordable compared to larger lathes. Second, they offer great precision, helping you create detailed pieces. Plus, they are compact, so you can fit one in a cozy corner. You might even say they’re the “tiny titan” of metal working!

| Advantages | Description |

|---|---|

| Cost-effective | Lower prices than big machines |

| Space-saving | Perfect for small work areas |

| Precision | Great for detailed work |

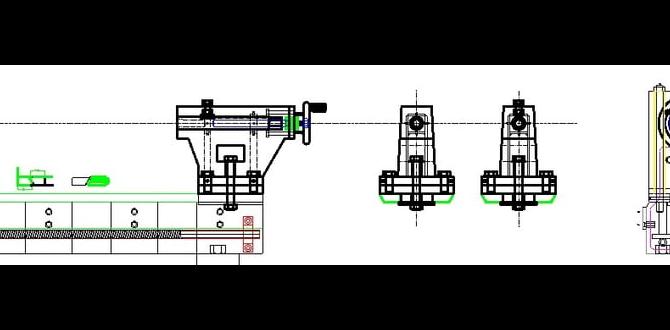

Key Components of Benchtop Metal Lathes

Breakdown of main components (headstock, tailstock, carriage). Importance of each component in the lathe’s functionality.Every benchtop metal lathe has three key parts: the headstock, tailstock, and carriage. Each has a special job that makes the lathe work properly.

- Headstock: This part holds the motor and spindle. It helps turn the metal piece.

- Tailstock: This piece supports the other end of the metal. It can be moved for different sizes.

- Carriage: It moves the cutting tool back and forth. This is how shapes are made.

These components work together to create precise shapes from metal. Without any of them, a lathe can’t function effectively.

Why are each of these components important?

Each part plays a vital role. The headstock provides power, the tailstock gives support, and the carriage brings movement. This teamwork makes incredible metalworking possible!

Benefits of CAD Design for Lathes

How CAD design improves precision and accuracy. Comparison of CAD design to traditional drafting methods.Using CAD design is like having a magic tool for lathes. It helps you create parts that fit perfectly every time. With CAD, you can design with precision and accuracy. This is much better than traditional drawing methods, which can be shaky and unclear.

Here are some quick benefits:

- Better detail in designs.

- Fewer mistakes in measurements.

- Faster design changes.

This means CAD design can make lathes do their best work!

How does CAD improve designs?

CAD design allows for easier adjustments, clearer visualizations, and better communication among team members. There is no need to guess or redo work, saving time and effort.

Steps to Create a CAD Design for a Benchtop Metal Lathe

Stepbystep process for designing with CAD software. Tips for ensuring design accuracy and functionality.Creating a CAD design for a benchtop metal lathe is an exciting journey. Start by choosing the right CAD software. Then, follow these easy steps:

- Sketch the basic shape of the lathe.

- Add important features like the motor mount.

- Ensure parts fit together snugly.

- Use measurements for accuracy.

- Review and test your design thoroughly.

Remember to double-check your work. Fun fact: A well-planned design saves you time and material! Always aim for precise measurements to ensure your lathe works well.

How can I improve my CAD design skills?

Practice makes perfect! You can take online courses for guidance. Make sure to study other successful designs and learn from them.

Common Design Challenges and Solutions

Identifying frequent issues in CAD designs. Problemsolving strategies to enhance design effectiveness.Designing a benchtop metal lathe in CAD can lead to some bumps in the road. Common issues include misalignment and unclear dimensions. Misalignment can happen due to a lack of precise measurements. It’s like trying to bake a cake without following the recipe—messy! To tackle these problems, double-check your measurements and use simple tools to visualize parts. Always follow standard design workflows to avoid chaos in your designs.

| Common Issues | Solutions |

|---|---|

| Misalignment | Double-check measurements |

| Unclear dimensions | Use clear labels and guides |

Integrating Design with Manufacturing Processes

How to transfer CAD designs to CNC machining. Importance of collaboration between design and manufacturing teams.To bring your CAD designs to life in CNC machining, start by converting your designs into a compatible file format. This step is like turning a secret recipe into a language your CNC machine understands. Next, teamwork between design and manufacturing teams matters! When these groups talk, they can solve problems faster. They can dodge mistakes like a pro athlete avoiding obstacles on the field. Good collaboration leads to fewer headaches and better results!

| Process | Details |

|---|---|

| CAD Conversion | Change designs to machine-friendly formats. |

| Collaboration | Design and manufacturing teams must communicate. |

Case Studies: Successful Benchtop Metal Lathe Designs

Examples of innovative designs and their outcomes. Lessons learned from each case study.Exploring new designs for benchtop metal lathes can be quite the adventure! One case involved a clever design that used 3D printing to create intricate parts. The outcome? A super light lathe that still packs a punch. Another example had a lathe with adjustable speeds, really helpful for making precise cuts. The lesson learned? Flexibility leads to fantastic results! Remember, innovation can turn a simple idea into an amazing tool.

| Design | Outcome | Lesson Learned |

|---|---|---|

| 3D Printed Parts | Lightweight, powerful lathe | Innovation is key! |

| Adjustable Speeds | Enhanced precision | Flexibility matters! |

Future Trends in Benchtop Metal Lathe CAD Design

Emerging technologies influencing CAD design. Predictions for the future of CAD and metal lathes.New tools and methods are changing how we design CAD for benchtop metal lathes. 3D printing is one exciting example. It helps create parts faster and more easily. AI technology is also making CAD smarter. It can suggest designs and catch mistakes. Future lathes may include features like:

- Smart sensors for monitoring

- Better software for users

- More data-sharing capabilities

Experts believe these advancements will make lathes more efficient and user-friendly.

What will CAD design look like in the future?

The future of CAD design is bright! More automation and real-time collaboration will make it easier to create and share designs.

Conclusion

In conclusion, a benchtop metal lathe combined with CAD design opens exciting possibilities for your projects. You can create precise parts safely and efficiently. This setup is perfect for beginners and hobbyists alike. We encourage you to explore CAD software tutorials and start designing your own projects. Hands-on practice will boost your skills and confidence!FAQs

What Are The Key Design Considerations For Creating A Cad Model Of A Benchtop Metal Lathe?When making a CAD model of a benchtop metal lathe, you should think about size first. The lathe must fit on your workbench. Next, you need to decide on the parts, like the bed and tailstock. You also want to ensure it can hold different kinds of metal. Finally, keep safety in mind to make sure everything works well and is safe to use.

How Can Simulation Software Be Utilized To Optimize The Performance Of A Benchtop Metal Lathe Design In Cad?We can use simulation software to test our metal lathe design before building it. This software helps us see how the machine will work. We can change parts to make it better. By doing this, we save time and money. In the end, we end up with a stronger and more efficient lathe.

What Specific Components Of A Benchtop Metal Lathe Should Be Detailed In A Cad Drawing For Accurate Manufacturing?When creating a CAD drawing of a benchtop metal lathe, you should include several parts. Draw the bed, which holds everything in place. Then, add the carriage, which moves the cutting tool. Don’t forget the tailstock, where you can support long pieces of metal. Lastly, show the motor and pulleys that help power the lathe. These parts help build a lathe that works well.

How Does The Choice Of Materials Impact The Cad Design And Overall Functionality Of A Benchtop Metal Lathe?The materials we choose for a benchtop metal lathe affect how strong and useful it is. For example, heavy metals make the lathe stable and less wobbly when it works. Lightweight materials are easier to move but might not be as strong. In CAD design, we can see how different materials change the lathe’s look and performance before we build it. This helps us make better choices for our project!

What Software Tools Are Recommended For Designing And Modeling Benchtop Metal Lathes In Cad?For designing and modeling benchtop metal lathes, you can use CAD software like SolidWorks, AutoCAD, or Fusion 360. These programs help you make 3D models of your lathe. They are user-friendly and great for both beginners and experts. You can create and test your designs easily using these tools.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Design Considerations For Creating A Cad Model Of A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making a CAD model of a benchtop metal lathe, you should think about size first. The lathe must fit on your workbench. Next, you need to decide on the parts, like the bed and tailstock. You also want to ensure it can hold different kinds of metal. Finally, keep safety in mind to make sure everything works well and is safe to use.”}},{“@type”: “Question”,”name”: “How Can Simulation Software Be Utilized To Optimize The Performance Of A Benchtop Metal Lathe Design In Cad? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use simulation software to test our metal lathe design before building it. This software helps us see how the machine will work. We can change parts to make it better. By doing this, we save time and money. In the end, we end up with a stronger and more efficient lathe.”}},{“@type”: “Question”,”name”: “What Specific Components Of A Benchtop Metal Lathe Should Be Detailed In A Cad Drawing For Accurate Manufacturing? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When creating a CAD drawing of a benchtop metal lathe, you should include several parts. Draw the bed, which holds everything in place. Then, add the carriage, which moves the cutting tool. Don’t forget the tailstock, where you can support long pieces of metal. Lastly, show the motor and pulleys that help power the lathe. These parts help build a lathe that works well.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Materials Impact The Cad Design And Overall Functionality Of A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The materials we choose for a benchtop metal lathe affect how strong and useful it is. For example, heavy metals make the lathe stable and less wobbly when it works. Lightweight materials are easier to move but might not be as strong. In CAD design, we can see how different materials change the lathe’s look and performance before we build it. This helps us make better choices for our project!”}},{“@type”: “Question”,”name”: “What Software Tools Are Recommended For Designing And Modeling Benchtop Metal Lathes In Cad? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For designing and modeling benchtop metal lathes, you can use CAD software like SolidWorks, AutoCAD, or Fusion 360. These programs help you make 3D models of your lathe. They are user-friendly and great for both beginners and experts. You can create and test your designs easily using these tools.”}}]}