Have you ever wondered how metal parts are made so precisely? It’s all thanks to machines like the benchtop metal lathe. This handy tool lets you shape and cut metal easily. But do you know what makes it work? The control panel!

The control panel is like the brain of the lathe. It helps you adjust settings and control the machine. Imagine being able to create anything from tiny screws to big gears! With the right control panel, it’s possible.

Fun fact: Some metal lathes are even so small they can fit on your desk! This means anyone can try their hand at metalworking. So, what should you know about the benchtop metal lathe control panel? Let’s explore!

Benchtop Metal Lathe Control Panel: Essential Features And Functions

Understanding the Benchtop Metal Lathe Control Panel

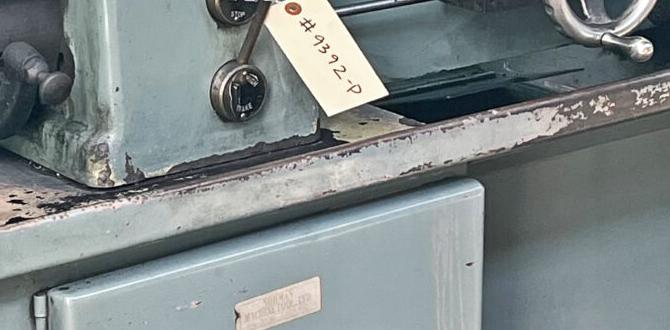

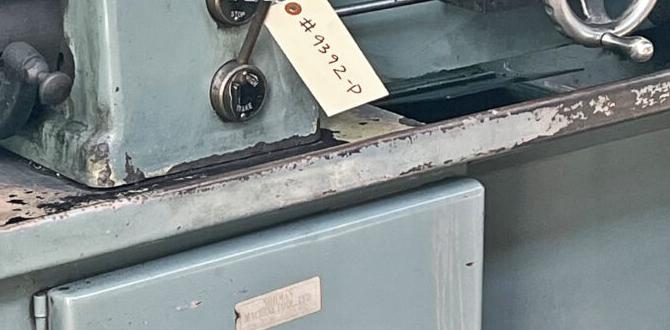

A benchtop metal lathe control panel is crucial in any workshop. It allows users to shape and cut metal accurately. With buttons and dials, these panels let you control speed and direction easily. Did you know some panels even include digital displays? This feature shows real-time data, helping you make quick adjustments. Whether you’re a beginner or an expert, knowing how to use these controls safely can lead to amazing projects. Curious about the possibilities?What is a Benchtop Metal Lathe Control Panel?

Definition and purpose of a control panel in metal lathes. Importance of control panels in the functionality of benchtop lathes.A control panel is the brain of a benchtop metal lathe. It helps users to manage and operate the machine effectively. With clear buttons and displays, it allows for precise adjustments while working. The control panel is vital for the lathe’s functionality, ensuring safety and efficiency. Without it, tasks could become difficult and unsafe. Think of it as the command center that guides the lathe in creating accurate pieces.

Why is the control panel important?

The control panel is crucial for smooth operations and safety in metal lathes. It helps users:

- Make precise adjustments.

- Monitor speed and feed rates.

- Stay safe while working.

Every feature is designed to enhance user experience. Remember, a good control panel can make all the difference in the workshop!

Types of Control Panels for Benchtop Metal Lathes

Comparison between analog and digital control panels. Advantages and disadvantages of each type.Control panels for benchtop metal lathes can be analog or digital. Analog panels use dials and gauges. They may be easier for some users since they provide clear, direct feedback. However, they lack advanced features and precision. Digital panels show numbers and often include programmable settings. They offer great accuracy, making them popular. Yet, they can be harder for beginners. Here’s a quick comparison:

- Analog Panels: Simple, reliable but less precise.

- Digital Panels: Accurate, versatile but may confuse new users.

What are the advantages and disadvantages of each type?

Analog panels are simple and easy to use, while digital panels are precise and feature-rich. Both have their pros and cons, depending on your needs.

How to Use a Benchtop Metal Lathe Control Panel Effectively

Stepbystep guide on operating a control panel. Tips for troubleshooting common issues.Operating a control panel for a benchtop metal lathe can be simple with the right steps. First, connect the power supply and ensure safety measures are in place. Next, select the desired settings on the panel. Adjust speed and feed rates carefully. Always double-check your setup before starting the machine. If issues arise, here are some troubleshooting tips:

- Check connections for loose wires.

- Reset the machine if it won’t start.

- Consult the manual for error codes.

By following these steps, you will use the control panel efficiently.

What common issues may occur with the control panel?

Common issues include power failures, misconfigurations, or unresponsive buttons. Identifying these problems quickly helps keep your workstation running smoothly.

Common Problems with Control Panels and Solutions

List of frequent malfunctions and their causes. Practical solutions and maintenance tips.Control panels can sometimes act up. Here are some common problems you might face:

- Buttons not responding: This can happen due to dirt or damage.

- Screen flickering: This may be caused by loose connections.

- Overheating: Make sure there’s enough airflow around the panel.

To fix these issues:

- Clean the buttons regularly.

- Check and secure the connections.

- Ensure vents are clear and use fans if needed.

Regular maintenance helps prevent problems. Happy machining!

What should I do if the control panel is unresponsive?

First, check the power supply. Next, clean the buttons and connections. If it’s still unresponsive, consult the manual or seek help from an expert.

Upgrading Your Benchtop Metal Lathe Control Panel

Factors to consider when upgrading. Recommended upgrades that enhance performance.When you think about upgrading a benchtop metal lathe control panel, some things matter. First, check the ease of use. A better layout helps you work faster. Next, consider compatibility. Make sure new parts fit your lathe. Finally, think about functions you don’t have now, like digital displays or speed controls. Recommended upgrades include:

- Improved displays for clarity

- Enhanced speed controls for better precision

- User-friendly interfaces for easier operation

What should I consider before upgrading?

Consider the cost and usefulness of the upgrades. Balance your budget with the improvements you need.

Recommended upgrades that enhance performance

Focus on features like digital readouts and precise speed control to make your work easier and more accurate.

Best Practices for Maintaining Your Control Panel

Regular maintenance routines to extend the life of the panel. Cleaning and care tips for optimal performance.To keep your control panel in top shape, follow some simple routines. Regularly check for dust and dirt; they can be sneaky little troublemakers! A quick wipe with a soft cloth can work wonders. Remember, moisture is not your friend. Keep your panel dry to avoid rust. If it starts to look a bit grumpy, sometimes a gentle cleaning with soap and water does the trick. Your control panel should be as shiny as a new penny!

| Maintenance Tip | Frequency |

|---|---|

| Dust Wipe | Weekly |

| Deep Clean | Monthly |

| Moisture Check | Regularly |

Follow these practices to extend the life of your panel. A little care goes a long way! And remember, a happy control panel will work like a charm, saving you from unexpected surprises.

Conclusion

In conclusion, a benchtop metal lathe control panel is essential for precise machining. It helps you manage speed and power safely. Understanding its features improves your projects and boosts your skills. We encourage you to explore your control panel further and practice using it. Try reading more guides on metal lathe operations to enhance your knowledge even more!FAQs

What Are The Essential Components Typically Found On A Benchtop Metal Lathe Control Panel?A benchtop metal lathe control panel has important parts you can see and touch. There’s a power switch to turn the machine on and off. You will also find knobs to control the speed of the lathe. A forward and reverse switch lets you change the direction of the tool. Finally, there are buttons for emergency stops, so you can quickly shut it down if needed.

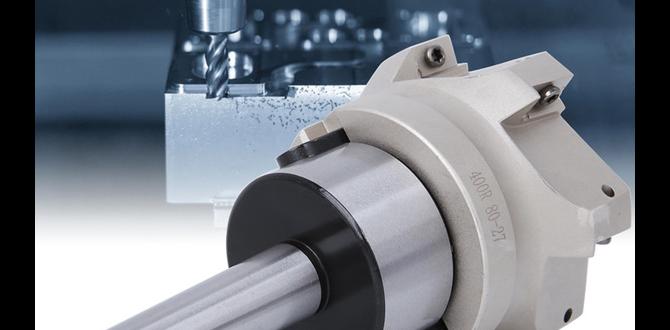

How Do The Control Settings On A Benchtop Metal Lathe Affect Machining Accuracy And Surface Finish?The control settings on a benchtop metal lathe decide how the machine moves. If you set it carefully, it cuts metal accurately. This helps make smooth surfaces, too. If the settings are wrong, the cuts can be wobbly and rough. So, good control means better work!

What Safety Features Should Be Included On The Control Panel Of A Benchtop Metal Lathe?A control panel for a benchtop metal lathe should have a big red emergency stop button. This button lets you stop the machine quickly if something goes wrong. There should also be clear labels for each switch, so you know what to do. A light to show when the machine is on can help keep you safe too. Finally, it’s good to have a safety cover to protect your hands while you work.

How Can Digital Displays And Programmable Controls Enhance The Functionality Of A Benchtop Metal Lathe?Digital displays on a benchtop metal lathe show important information, like speed and measurements. This makes it easier for you to see what you’re doing. Programmable controls let you set specific tasks, helping you make the same part over and over accurately. This saves time and helps you create better projects. Overall, they make using the lathe simpler and more fun!

What Maintenance Practices Are Recommended For The Control Panel Of A Benchtop Metal Lathe To Ensure Reliable Operation?To keep the control panel of a benchtop metal lathe working well, you should check it often. Clean the panel with a soft cloth to remove dust and dirt. Make sure all buttons and switches work properly. Look for loose wires or parts and fix them right away. Finally, keep the area around the lathe tidy to prevent accidents.