Have you ever wondered how metal parts are shaped with such precision? A benchtop metal lathe motor plays a key role in this process. This handy tool helps hobbyists and professionals create everything from small gears to intricate designs.

Picture this: you’re in a workshop, surrounded by tools. The sound of the lathe humming fills the air. You hold a piece of metal, ready to turn it into something amazing. The benchtop lathe motor makes it all happen.

Did you know that these motors can spin at different speeds? This allows for great flexibility in your projects. Faster speeds can cut quicker, while slower speeds give you better control.

In this article, we will explore how to choose the right benchtop metal lathe motor. We’ll also look at tips to keep your lathe running smoothly. Get ready to dive into the world of metalworking, where creativity meets power!

Benchtop Metal Lathe Motor: Enhancing Your Machining Skills

Benchtop Metal Lathe Motor

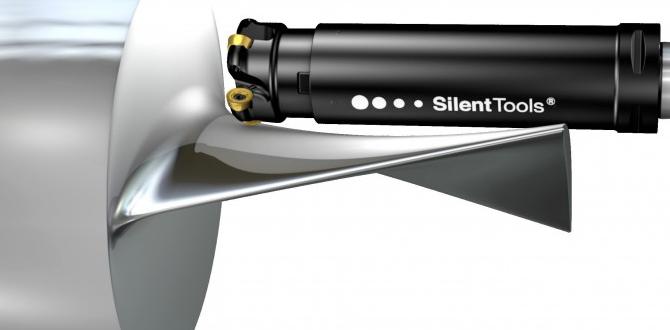

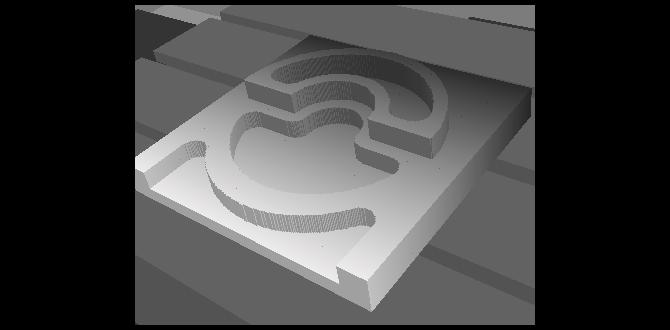

A benchtop metal lathe motor is essential for small metalworking projects. It drives the lathe, allowing for precise cuts and shaping. Did you know that a good motor can dramatically increase your lathe’s performance? Choosing the right power rating impacts your projects significantly. Consider factors like speed and torque for the best results. With the right motor, you can create intricate designs and parts, making metalworking both exciting and rewarding.What is a Benchtop Metal Lathe Motor?

Definition and function of a benchtop metal lathe motor. Importance in machining and metalworking processes.A benchtop metal lathe motor is a powerful little engine that spins tools to shape metal. Picture it as a tiny dragon, whirring away to make your projects neat and precise. Its main job? Transforming raw metal into useful parts! This motor is crucial for machining and metalworking, helping craftsmen create everything from gears to jewelry. Without it, you’d be stuck with just a pile of metal, and who wants that? So, think of it as your buddy in the workshop!

| Function | Importance |

|---|---|

| Shapes metal into desired forms | Essential for accurate machining |

| Drills and cuts materials | Speeds up metalworking processes |

| Supports various tools | Versatile for many projects |

How to Choose the Right Motor for Your Benchtop Lathe

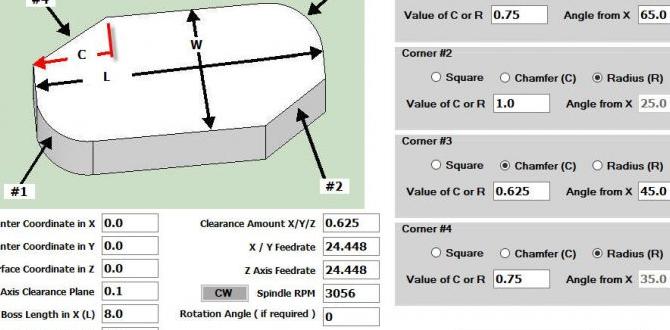

Key factors to consider (power, speed, size). Compatibility with different lathe models.Choosing the right motor for your lathe is like picking the best ice cream flavor; it’s all about personal taste! Start with power. A good motor should have enough oomph to get the job done. Next is speed; a motor that spins too fast might leave you dizzy, while one that’s too slow can test your patience. Lastly, check the size. It should fit well with your benchtop lathe. Also, don’t forget compatibility with different lathe models; you want a match made in motor heaven!

| Factor | Importance |

|---|---|

| Power | Essential for effective cutting. |

| Speed | Determines how fast you can work. |

| Size | Makes sure it fits your lathe. |

Installation Guide for Benchtop Metal Lathe Motors

Stepbystep process for motor installation. Common mistakes to avoid during installation.Installing a benchtop metal lathe motor can be simple and fun. Start by gathering your tools and reading the manual. First, securely mount the motor to the lathe. Be sure not to force it, as that can lead to problems. Next, connect the wires carefully — no one wants to create a spark show! Check all screws and bolts to make sure they’re tight. To help you avoid common hiccups, see the table below:

| Common Mistakes | What to Do Instead |

|---|---|

| Forgetting to turn off the power | Always disconnect it before starting! |

| Incorrect wire connections | Double-check your wiring diagram. |

| Ignoring vibrations | Ensure all parts are secure and balanced. |

By following these steps, you’ll have your motor purring like a kitten in no time. Remember, a little patience goes a long way, and your lathe will thank you for it!

Maintenance Tips for Longevity of Your Benchtop Lathe Motor

Routine maintenance practices. Signs of motor wear and how to address them.To keep your metal lathe motor running smoothly, routine maintenance is key. Check the motor’s belt for wear and ensure it’s tight. Clean any dust or debris from the fan to keep it cool. Watch for signs like strange noises or slower speeds. These can mean your motor needs help. Catching issues early can save you from bigger headaches later!

| Signs of Wear | Action |

|---|---|

| Odd noises | Inspect parts immediately |

| Reduced speed | Check belt tension |

| Vibrations | Tighten loose screws |

By giving your lathe motor some love, it will reward you with better performance. Remember, a happy motor makes for a happy hobbyist!

Upgrading Your Benchtop Metal Lathe Motor

Benefits of upgrading for performance and efficiency. Considerations before making an upgrade.Upgrading your lathe motor is like giving your bench a turbo boost! With a better motor, you can cut metal faster and smoother, making your projects shine. Just think about the peace of mind that comes when things run efficiently—no more waiting around. Before you rush off to the store, consider a few things first. Check out these points:

| Benefit | Consideration |

|---|---|

| Improved Speed | Will it fit your current setup? |

| Better Precision | Is it within your budget? |

| Energy Efficiency | How much power do you need? |

With a little planning, you’ll soon have your lathe buzzing along like a happy bee! Get ready to make some cool stuff.

Common Problems and Troubleshooting Tips

List of frequent motor issues. How to diagnose and resolve motor problems.Motors in benchtop metal lathes can face issues. Common problems include:

- Motor not starting

- Unusual noises

- Overheating

- Vibration or shaking

To diagnose these issues, check the power supply first. Ensure all connections are secure. If the motor makes strange sounds, inspect for any loose parts. Overheating often signals too much load. Take some time to adjust tools and reduce stress on the motor.

How can I fix common motor issues?

You can fix many motor problems by following simple steps. For example, if your motor won’t start, check the outlet and power cord. This can often solve the issue quickly.

Top Brands and Models of Benchtop Metal Lathe Motors

Review of leading brands in the market. Comparison of popular models and their features.Many brands offer top-quality benchtop metal lathe motors. Some leading names are Grizzly, Jet, and Shop Fox. Each brand has its own unique features. For example, Grizzly models focus on durability, while Jet motors are known for their precision. Shop Fox offers great value for money. Here’s a quick comparison:

- Grizzly G8688: Strong motor, easy to use.

- Jet JWL-1221VS: Variable speed control, very precise.

- Shop Fox M1015: Affordable, good for beginners.

Conclusion

In summary, a benchtop metal lathe motor is a powerful tool for shaping metal. It’s great for hobbyists and professionals alike. You can create precise parts and projects with it. If you’re interested, consider exploring lathe tutorials or safety guides. These resources will help you use your lathe effectively. Start your metalworking journey today and enjoy the creativity!FAQs

What Are The Key Specifications To Consider When Selecting A Motor For A Benchtop Metal Lathe?When choosing a motor for a benchtop metal lathe, you should check the power, speed, and size. Power tells how strong the motor is, usually measured in horsepower (HP). Speed shows how fast the motor can turn, often given in rotations per minute (RPM). Make sure the motor fits well in your lathe space, too. This way, the lathe will work better for you!

How Does The Power Of The Motor Affect The Machining Capabilities Of A Benchtop Metal Lathe?The power of the motor on a benchtop metal lathe helps it cut metal better. A stronger motor can handle tougher jobs and cut through harder materials. If the motor is weak, it might slow down or get stuck. So, a powerful motor lets you do more with your lathe. This means you can make better and more detailed parts!

What Are The Advantages Of Using A Brushless Motor Compared To A Brushed Motor In A Benchtop Metal Lathe?Brushless motors have some cool advantages over brushed motors in a metal lathe. They last longer because they don’t have brushes that wear out. They also work more quietly and smoothly, which is nice when you’re working. Plus, they are more efficient, so you get more power for less energy. This means you can work better and save money on electricity!

How Can One Efficiently Troubleshoot Motor Issues In A Benchtop Metal Lathe?To troubleshoot motor issues in a benchtop metal lathe, first check the power supply. Make sure the lathe is plugged in and the outlet works. Next, listen for any strange sounds when you turn it on. If you hear noise, the motor might be stuck. Finally, inspect the wires for any damages. If everything looks okay but it still doesn’t work, you might need help from a professional.

What Type Of Motor Control Systems Are Commonly Used In Benchtop Metal Lathes, And How Do They Influence Performance?Benchtop metal lathes often use DC (direct current) motors or stepper motors. These motors help you control the speed and direction easily. With a good motor, you get smooth cuts and better shapes on the metal. This makes your projects look nicer and work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Specifications To Consider When Selecting A Motor For A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a motor for a benchtop metal lathe, you should check the power, speed, and size. Power tells how strong the motor is, usually measured in horsepower (HP). Speed shows how fast the motor can turn, often given in rotations per minute (RPM). Make sure the motor fits well in your lathe space, too. This way, the lathe will work better for you!”}},{“@type”: “Question”,”name”: “How Does The Power Of The Motor Affect The Machining Capabilities Of A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power of the motor on a benchtop metal lathe helps it cut metal better. A stronger motor can handle tougher jobs and cut through harder materials. If the motor is weak, it might slow down or get stuck. So, a powerful motor lets you do more with your lathe. This means you can make better and more detailed parts!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Brushless Motor Compared To A Brushed Motor In A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Brushless motors have some cool advantages over brushed motors in a metal lathe. They last longer because they don’t have brushes that wear out. They also work more quietly and smoothly, which is nice when you’re working. Plus, they are more efficient, so you get more power for less energy. This means you can work better and save money on electricity!”}},{“@type”: “Question”,”name”: “How Can One Efficiently Troubleshoot Motor Issues In A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot motor issues in a benchtop metal lathe, first check the power supply. Make sure the lathe is plugged in and the outlet works. Next, listen for any strange sounds when you turn it on. If you hear noise, the motor might be stuck. Finally, inspect the wires for any damages. If everything looks okay but it still doesn’t work, you might need help from a professional.”}},{“@type”: “Question”,”name”: “What Type Of Motor Control Systems Are Commonly Used In Benchtop Metal Lathes, And How Do They Influence Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Benchtop metal lathes often use DC (direct current) motors or stepper motors. These motors help you control the speed and direction easily. With a good motor, you get smooth cuts and better shapes on the metal. This makes your projects look nicer and work better.”}}]}