Have you ever watched a metal lathe spin? It’s fascinating how a simple block of metal can be shaped into something amazing. At the heart of this process is the benchtop metal lathe saddle. But what exactly is a saddle?

A saddle is a key part in a metal lathe. It holds and guides the cutting tools as they move. Imagine trying to ride a bike without a seat; it would be hard to steer! The saddle helps control the tools for precise cuts, making it essential for any metalworking project.

Did you know that many DIY enthusiasts start with a benchtop metal lathe? These machines are perfect for small spaces. They can help create everything from jewelry to engine parts. Each project teaches valuable skills. Excited to learn more about how a benchtop metal lathe saddle can change your crafting experience? Let’s dive in!

Understanding The Benchtop Metal Lathe Saddle Design And Use

Overview of Benchtop Metal Lathe Saddle

The benchtop metal lathe saddle is a key component for precise machining. It helps hold the workpiece steady while the lathe spins it. Did you know that a well-maintained saddle can significantly improve your lathe’s accuracy? Using a metal lathe can be a fun way to create unique projects. Proper care of the saddle also extends the machine’s life. Explore ways to optimize your benchtop lathe for better results and smoother operation!Types of Benchtop Metal Lathe Saddles

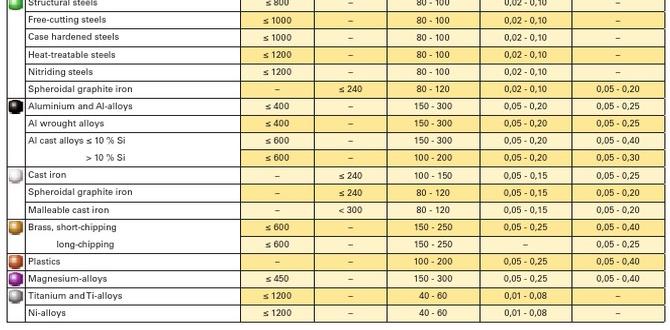

Comparison of different saddle designs (fixed vs. sliding). Material variations and their impact on performance.When choosing a saddle for a benchtop metal lathe, consider two main designs: fixed and sliding. Fixed saddles stay in place. They are sturdy and great for precision tasks. Sliding saddles can move back and forth. This makes them flexible for different jobs. The material used also matters. Aluminum is light and easy to handle. Steel offers strength and durability. Each choice can affect how well the lathe performs.

What are the benefits of fixed and sliding saddles?

Fixed saddles provide stability, while sliding saddles allow movements for various tasks.

Key Features of an Effective Saddle

Importance of rigidity and stability. Precision control systems and their functionalities.Having a sturdy saddle on your benchtop metal lathe is crucial. A strong design offers rigidity and stability. Without it, your projects might wobble like a cat on a hot tin roof! Precision control systems help you turn ideas into reality. They ensure your cuts are exact and smooth. Sure, nobody wants their metal work to look like Swiss cheese. With the right saddle, you can unleash your creativity and craft with confidence!

| Feature | Importance |

|---|---|

| Rigidity | Minimizes vibration, ensuring accuracy |

| Stability | Prevents slipping and unwanted movement |

| Precision Control | Allows for fine adjustments in cutting |

How to Choose the Right Saddle for Your Benchtop Lathe

Factors to consider (size, compatibility, and usage). Tips for assessing quality and durability.Selecting the right saddle for your benchtop lathe is essential for smooth operation. Here are some factors to keep in mind:

- Size: Ensure the saddle matches your lathe’s dimensions.

- Compatibility: Check if it’s designed for your specific lathe model.

- Usage: Think about what projects you plan on doing.

Also, assess the quality and durability. Look for:

- Sturdy materials that resist wear.

- Positive reviews from trusted sources.

- A warranty that shows the manufacturer’s confidence.

Making the right choice can enhance your lathe experience.

What should I consider when buying a saddle?

Consider size, compatibility, and intended use for the best results. A correct size ensures a snug fit, while compatibility means it works well with your lathe model.

Common Problems and Troubleshooting with Benchtop Metal Lathe Saddles

Identifying issues related to wear and tear. Solutions for maintenance and repair. “`htmlBenchtop metal lathe saddles can have their fair share of hiccups. Common issues include wear and tear, like wobbly movement or strange noises. It’s like your lathe is trying to sing! Regular maintenance is key. Keep it clean and lubricated to avoid grumpy performances. If you spot a problem, don’t panic. Most can be fixed with some simple tools and elbow grease. Here’s a handy table for quick fixes:

| Issue | Possible Cause | Solution |

|---|---|---|

| Wobbly Saddle | Wear on bearings | Replace or tighten bearings |

| Noisy Movement | Lack of lubrication | Apply machine oil |

| Sticking Parts | Dust buildup | Clean all surfaces |

Keeping a sharp eye on these issues will help keep your lathe happy and ready to work! After all, a happy lathe makes for happy projects!

“`Upgrades and Modifications for Enhanced Performance

Popular aftermarket saddles and their benefits. DIY modifications for improved function.Upgrading your saddle can work wonders for your benchtop metal lathe. Popular aftermarket saddles often have better precision and stability. They can help you make smoother cuts without tears. DIY modifications also boost performance. Adding better bearings or tightening metal parts enhances overall efficiency. Who wouldn’t want a lathe that runs smoother than a penguin on ice? Check out the benefits in the table below:

| Modification Type | Benefits |

|---|---|

| Aftermarket Saddle | Improved accuracy and stability |

| DIY Bearings Upgrade | Smoother movement |

| Component Tightening | Better efficiency |

Safety Precautions When Using a Metal Lathe Saddle

Importance of safety gear and protocols. Common hazards associated with lathe operations.Using a metal lathe safely is very important. Always wear safety gear like goggles and gloves. This protects you from flying debris and sharp edges. Follow these safety protocols:

- Keep the workspace tidy.

- Do not wear loose clothing.

- Stay focused while working.

Common hazards include:

- Getting caught in moving parts.

- Injuries from sharp tools.

- Noise that can hurt your ears.

Being cautious helps everyone stay safe!

What should I always wear when using a lathe?

Always wear safety goggles to protect your eyes from debris and gloves to shield your hands from sharp edges.

Real-World Applications of Benchtop Metal Lathe Saddles

Industries that utilize metal lathes. Examples of projects and tasks suited for benchtop lathes.Many industries use benchtop metal lathes for various tasks. They create parts for cars, planes, and machines. These lathe saddles help in making small, precise items.

- Jewelry making for unique designs

- Engineering prototypes to test ideas

- Repairing tools and equipment

- Making custom parts for hobbies

These projects show the versatility of benchtop lathes. With them, creativity meets precision in everyday tasks.

What can a benchtop metal lathe create?

Benchtop lathes can create small parts, prototypes, and even jewelry. They are great for both professionals and hobbyists.

Expert Tips for Maximizing Saddle Efficiency

Techniques for proper setup and alignment. Best practices for regular maintenance and care.To get the most out of your saddle on a benchtop metal lathe, careful setup and maintenance are key. Start by aligning the saddle properly. This helps in smoother operations. Regularly check for dirt and oil on the components. Clean them to keep everything running well. Here are some best practices:

- Ensure proper alignment each time you set up.

- Check for wear and tear on a schedule.

- Lubricate moving parts frequently.

- Store the lathe in a clean, dry area.

With these tips, your saddle will work efficiently. It’s like keeping a bike in good shape – regular care leads to great rides!

How often should I maintain my benchtop metal lathe saddle?

Regular maintenance is essential. You should check the saddle every month for wear and clean it regularly. Use light oil to keep it smooth and functioning well.

Conclusion

In conclusion, the benchtop metal lathe saddle is vital for precision in metalworking. It supports the workpiece and helps you create accurate cuts. You can improve your projects by choosing a quality saddle for your lathe. Explore more resources or tutorials to enhance your skills and learn how to use it effectively. Happy crafting!FAQs

Sure! Here Are Five Questions Related To The Topic Of A Benchtop Metal Lathe Saddle:Sure! A benchtop metal lathe saddle holds the part you are working on. It moves side to side and up and down. This helps you shape the metal correctly. You can adjust the saddle to fit different sizes of metal. Using it makes your projects easier and more accurate.

Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help!

What Is The Primary Function Of The Saddle In A Benchtop Metal Lathe?The saddle is a part of a benchtop metal lathe. It helps hold the cutting tool in place. You move the saddle to get the tool closer or further from the metal. This way, we can shape the metal correctly. The saddle makes our work easier and more precise.

How Can I Ensure Proper Alignment And Smooth Movement Of The Saddle On My Benchtop Metal Lathe?To keep the saddle on your metal lathe moving well, start by cleaning it. Remove dust and grime. Next, check that all the screws are tight but not too tight. You can also add some oil to the moving parts. Finally, move the saddle back and forth to make sure it slides smoothly.

What Materials Are Commonly Used To Construct The Saddle Of A Benchtop Metal Lathe, And How Do They Affect Performance?The saddle of a benchtop metal lathe is usually made of strong materials like cast iron or steel. Cast iron is heavy and helps keep the lathe steady, which means it cuts better. Steel is tough and can handle lots of use without breaking. These materials make the lathe more stable and accurate when you’re working on metal.

How Do Wear And Tear On The Saddle Impact The Accuracy And Precision Of Machining Operations On A Lathe?When the saddle on a lathe wears down, it can cause problems. The saddle holds the tools in place. If it’s not steady, the tools may shake or move. This makes the cuts less accurate and not as precise as we want. It’s like trying to draw a straight line with a wobbly pencil!

What Are Some Signs That The Saddle Of A Benchtop Metal Lathe May Require Maintenance Or Replacement?You might notice some problems with the lathe’s saddle. First, check for any unusual noises while it runs. If the cuts are rough or uneven, that’s a sign too. You might also see worn out parts or rust. These signs mean it’s time to clean, fix, or replace the saddle.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of A Benchtop Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A benchtop metal lathe saddle holds the part you are working on. It moves side to side and up and down. This helps you shape the metal correctly. You can adjust the saddle to fit different sizes of metal. Using it makes your projects easier and more accurate.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Saddle In A Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle is a part of a benchtop metal lathe. It helps hold the cutting tool in place. You move the saddle to get the tool closer or further from the metal. This way, we can shape the metal correctly. The saddle makes our work easier and more precise.”}},{“@type”: “Question”,”name”: “How Can I Ensure Proper Alignment And Smooth Movement Of The Saddle On My Benchtop Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the saddle on your metal lathe moving well, start by cleaning it. Remove dust and grime. Next, check that all the screws are tight but not too tight. You can also add some oil to the moving parts. Finally, move the saddle back and forth to make sure it slides smoothly.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Construct The Saddle Of A Benchtop Metal Lathe, And How Do They Affect Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The saddle of a benchtop metal lathe is usually made of strong materials like cast iron or steel. Cast iron is heavy and helps keep the lathe steady, which means it cuts better. Steel is tough and can handle lots of use without breaking. These materials make the lathe more stable and accurate when you’re working on metal.”}},{“@type”: “Question”,”name”: “How Do Wear And Tear On The Saddle Impact The Accuracy And Precision Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the saddle on a lathe wears down, it can cause problems. The saddle holds the tools in place. If it’s not steady, the tools may shake or move. This makes the cuts less accurate and not as precise as we want. It’s like trying to draw a straight line with a wobbly pencil!”}},{“@type”: “Question”,”name”: “What Are Some Signs That The Saddle Of A Benchtop Metal Lathe May Require Maintenance Or Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice some problems with the lathe’s saddle. First, check for any unusual noises while it runs. If the cuts are rough or uneven, that’s a sign too. You might also see worn out parts or rust. These signs mean it’s time to clean, fix, or replace the saddle.”}}]}