Have you ever tried to make something on a lathe, only to find that it didn’t look right? It’s frustrating, isn’t it? One big reason for this can be a misaligned tailstock on your benchtop metal lathe. The tailstock is crucial because it helps hold the other end of the workpiece. If it’s not aligned properly, your work may come out uneven or even ruin it.

Many hobbyists don’t realize how important tailstock alignment is. Here’s a fun fact: Did you know that even a tiny misalignment can turn a perfect piece of metal into scrap? That’s why learning about how to align your tailstock is key for anyone using a benchtop metal lathe.

In this article, we will explore simple ways to check and fix the tailstock alignment. Are you ready to make your projects smoother and more accurate? Let’s dive into the world of metal lathes and make your crafting experience better!

Benchtop Metal Lathe Tailstock Alignment: A Key Guide

Benchtop Metal Lathe Tailstock Alignment

Tailstock alignment on a benchtop metal lathe is crucial for precise machining. Poor alignment can lead to uneven cuts and ruined projects. To check alignment, ensure the tailstock aligns perfectly with the spindle. Small adjustments can make a big difference. Imagine working hard on a piece, only to find it not fitting right due to misalignment! Learning to align your lathe will save time and boost your skill. You’ll create better workpieces and enjoy your projects even more!Understanding Tailstock Alignment

Definition and importance of tailstock alignment in metal lathes. Common issues caused by misalignment.Tailstock alignment is key in using a metal lathe. It ensures that the tailstock is perfectly lined up with the spindle. If it’s off, parts become uneven. Imagine trying to draw a straight line with a bent pencil! Misalignment can lead to problems like poor accuracy and uneven cuts. This can make your projects look like they were made by a toddler!

| Common Issues | Effects |

|---|---|

| Tool wear | Reduced lifespan |

| Surface finish | Poor appearance |

| Precision | Increased error |

Proper alignment keeps everything in check. This leads to better results, smoother operations, and happy users! So, take a moment to check your alignment; it’s worth it, trust me!

Tools and Equipment Needed for Tailstock Alignment

List of essential tools for proper alignment. Explanation of how each tool is used in the alignment process.To set up your tailstock perfectly, you need a few important tools. Each one helps make the task easier and more precise. Here’s what you need:

- Caliper: This is used to measure distances very accurately.

- Taper Gauge: Use this to check angles and fit between parts.

- Adjustment Wrenches: These help tighten or loosen screws for adjustments.

- Laser Level: A handy tool that ensures everything is straight and aligned.

With these tools, your tailstock alignment will be precise, leading to better projects and smoother operations.

What tools do I need for tailstock alignment?

For proper benchtop metal lathe tailstock alignment, the essential tools include a caliper, taper gauge, adjustment wrenches, and a laser level. These tools ensure that your adjustments are accurate and reliable.

Step-by-Step Tailstock Alignment Process

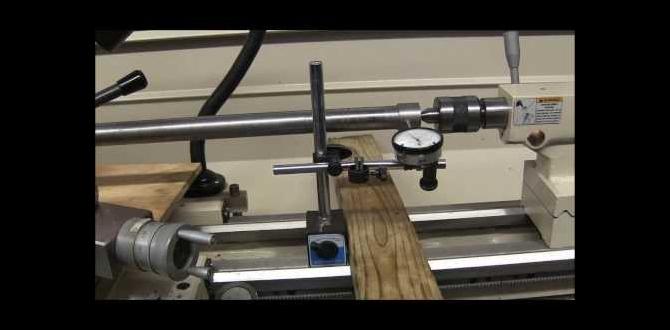

Detailed procedure for aligning the tailstock. Tips for ensuring accuracy during the alignment.First, make sure your lathe is off. Safety first! To align the tailstock, loosen the tailstock clamping screws. Gently move it until the center of the tailstock aligns with the spindle. You can use a dial indicator for precision. A sharp eye and a steady hand will help here.

For accuracy, check alignment with a test bar. Tighten the tailstock screws and measure again to see if it’s close. If not, adjust and repeat. Remember, patience is key! And always double-check your work. The last thing you want is a crooked cut – unless you’re trying to carve a funky shape!

| Steps | Tips |

|---|---|

| Turn off the lathe. | Safety first! |

| Loosen clamping screws. | Stay gentle, avoid sudden moves. |

| Align tailstock with spindle. | Use a dial indicator. |

| Tighten the screws. | Check alignment again. |

With these tips, you’ll have a tailstock that is as straight as an arrow (or maybe even straighter). Happy turning!

Common Mistakes to Avoid in Tailstock Alignment

Frequent errors made by users during the alignment process. Impact of these mistakes on machining quality.Many users make simple mistakes during tailstock alignment. These errors can hurt the quality of their work. Here are some common errors:

- Not checking the tailstock height.

- Ignoring the bed’s levelness.

- Failing to tighten the tailstock securely.

These mistakes lead to uneven cuts and poor finishes. Always double-check your setup to ensure smooth machining!

What are the effects of poor tailstock alignment?

Poor tailstock alignment can cause issues like vibration and bad cuts. This lowers the quality of your project and wastes materials.

Maintaining Tailstock Alignment Over Time

Best practices for regular maintenance. Signs that indicate a need for realignment.Keeping your tailstock aligned is like ensuring your shoelaces are tied—important and easy to overlook. Regular maintenance helps your lathe run smoothly. Check the alignment every few weeks. If you notice uneven cuts or if the tailstock feels loose, it’s time for a check-up. Your projects deserve a good finish, not a wobbly disaster! Below is a quick guide for better tailstock health:

| Best Practices | Signs of Misalignment |

|---|---|

| Check alignment weekly | Uneven cuts observed |

| Lubricate regularly | Loose tailstock |

| Tighten screws properly | Difficulty in adjusting |

Frequently Asked Questions About Tailstock Alignment

Common queries and expert answers. Clarifying misconceptions related to tailstock adjustments.Many people have questions about alignments for the tailstock on their benchtop metal lathes. Here are some answers to common queries:

What is tailstock alignment?

Tailstock alignment refers to how well the tailstock fits with the lathe’s spindle. Good alignment helps make smooth cuts.

How do I check if my tailstock is aligned?

You can check alignment with a dial indicator or a test bar. Place it in the spindle, then move the tailstock close. Measure any differences.

Why does alignment matter?

Alignment is vital for accuracy. A misaligned tailstock can lead to uneven cuts and wasted materials.

Common misconceptions

- It is only for experts: Anyone can learn to align the tailstock.

- It’s hard to do: Simple tools can help check and fix alignment easily.

Conclusion

In conclusion, proper tailstock alignment on your benchtop metal lathe is crucial for accurate machining. Remember to check the alignment regularly for the best results. This ensures smooth operation and better quality work. Next, practice adjusting your tailstock as needed. For more tips, explore guides and videos on lathe maintenance. Happy machining!FAQs

What Are The Key Steps To Properly Align The Tailstock On A Benchtop Metal Lathe?To align the tailstock on a benchtop metal lathe, first, check that the lathe is on a flat surface. Next, loosen the tailstock clamp so you can move it. Then, slide the tailstock until it is in line with the spindle, which holds the workpiece. Finally, tighten the clamp to keep it in place. You can check the alignment again to make sure it’s correct.

How Can Misalignment Of The Tailstock Affect The Accuracy Of Machined Parts?If the tailstock is not lined up correctly, it can cause problems when we make parts. It can make the holes too big or too small. This happens because the tool doesn’t cut in the right spot. When the tailstock is off, our finished parts may not fit together well. We want everything to be just right, so alignment is very important!

What Tools Are Commonly Used To Check And Adjust The Alignment Of A Lathe’S Tailstock?To check and adjust the tailstock of a lathe, we use a few simple tools. A center gauge helps us see if the tailstock points straight. A dial indicator measures tiny changes in position. A ruler can also help us measure distances accurately. These tools make sure everything is lined up just right.

How Often Should The Tailstock Alignment Be Checked And Recalibrated For Optimal Performance?You should check the tailstock alignment every time you set up your machine. This helps you make sure everything is correct from the start. If you notice any problems while working, recheck it right away. Doing this helps your projects turn out better and keeps your machine running well.

What Are The Signs That Indicate A Tailstock Is Out Of Alignment On A Benchtop Metal Lathe?If the tailstock is out of alignment, you might see problems when you’re cutting metal. The tool can make uneven marks or scratches. You could also notice your parts are not the same length or size. Sometimes, the drill bit might not go straight into the metal. These signs mean that the tailstock needs to be fixed to work correctly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Steps To Properly Align The Tailstock On A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a benchtop metal lathe, first, check that the lathe is on a flat surface. Next, loosen the tailstock clamp so you can move it. Then, slide the tailstock until it is in line with the spindle, which holds the workpiece. Finally, tighten the clamp to keep it in place. You can check the alignment again to make sure it’s correct.”}},{“@type”: “Question”,”name”: “How Can Misalignment Of The Tailstock Affect The Accuracy Of Machined Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock is not lined up correctly, it can cause problems when we make parts. It can make the holes too big or too small. This happens because the tool doesn’t cut in the right spot. When the tailstock is off, our finished parts may not fit together well. We want everything to be just right, so alignment is very important!”}},{“@type”: “Question”,”name”: “What Tools Are Commonly Used To Check And Adjust The Alignment Of A Lathe’S Tailstock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the tailstock of a lathe, we use a few simple tools. A center gauge helps us see if the tailstock points straight. A dial indicator measures tiny changes in position. A ruler can also help us measure distances accurately. These tools make sure everything is lined up just right.”}},{“@type”: “Question”,”name”: “How Often Should The Tailstock Alignment Be Checked And Recalibrated For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the tailstock alignment every time you set up your machine. This helps you make sure everything is correct from the start. If you notice any problems while working, recheck it right away. Doing this helps your projects turn out better and keeps your machine running well.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Tailstock Is Out Of Alignment On A Benchtop Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock is out of alignment, you might see problems when you’re cutting metal. The tool can make uneven marks or scratches. You could also notice your parts are not the same length or size. Sometimes, the drill bit might not go straight into the metal. These signs mean that the tailstock needs to be fixed to work correctly.”}}]}