A milling machine is a versatile tool that has become a staple worldwide in workshops and manufacturing facilities. Its ability to shape and manipulate various materials makes it an essential piece of equipment for professionals and hobbyists alike.

However, with the vast array of options available in the market, choosing the right benchtop milling machine for your workshop can seem like a daunting task. From size and power to features and price, there are many factors to consider before purchasing. That’s where we come in.

Here, we will explore the best available benchtop milling machine options, considering their features, capabilities, and overall value for money. Whether you are a seasoned professional or a beginner looking to set up your workshop, this guide will provide you with all the necessary information to make an informed decision.

Guide To The Best Benchtop Milling Machine Options For Your Workshop

equipping your workshop with the necessary tools, a benchtop milling machine should not be overlooked. With its compact size and versatility, a benchtop milling machine offers a range of options that can greatly enhance your workshop capabilities. Whether you are a hobbyist or a professional, having a benchtop milling machine can open up a world of possibilities.

One of the key advantages of a benchtop milling machine is its ability to handle a wide range of materials. From metal to wood and even plastic, these machines are designed to accommodate different materials with precision and efficiency. This versatility allows you to work on various projects without needing multiple machines, saving space and money.

1.Little Machine Shop Hi Torque Mini Mill

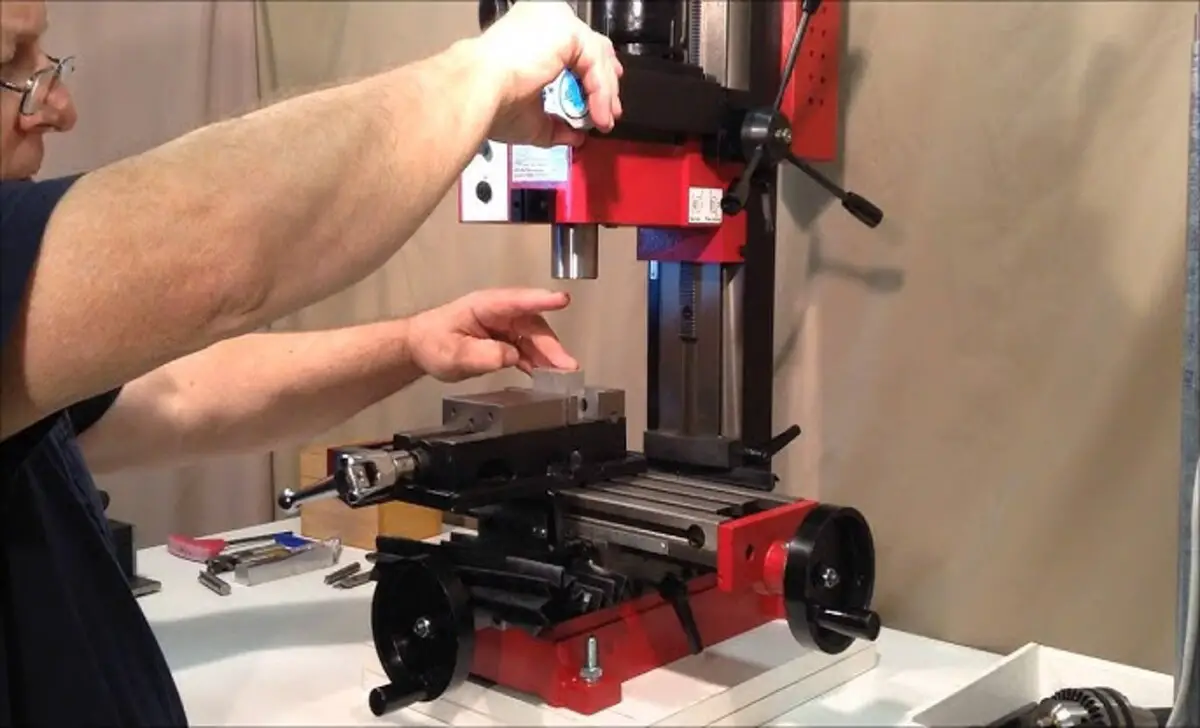

The Little Machine Shop Hi Torque Mini Mill is a compact milling machine renowned for its high torque and precision. This mini mill is perfect for hobbyists, small workshops, and DIY enthusiasts who require a reliable and versatile tool for their machining needs.

With its solid construction and powerful motor, the Hi Torque Mini Mill can handle various materials, from wood to metal. It offers smooth operation and precise control, allowing users to achieve accurate cuts and fine details in their projects. Whether you are working on small-scale prototypes or intricate designs, the Little Machine Shop Hi Torque Mini Mill is a reliable choice that delivers quality results.

Features And Specifications

The Little Machine Shop Hi Torque Mini Mill is a compact, versatile milling machine perfect for small-scale machining projects. This mini mill features a solid cast iron construction, ensuring durability and stability during operation. It offers a generous travel range of 12 inches on the X-axis and 7 inches on the Y-axis, allowing for precision milling and drilling.

The Hi Torque Mini Mill has a powerful 500W brushless DC motor, providing smooth and efficient operation. It also has a digital spindle speed readout, allowing precise speed control. With its compact size and impressive features, the Little Machine Shop Hi Torque Mini Mill is an excellent choice for hobbyists, small workshops, and educational institutions.

Pros

- Compact size, perfect for small workshops or home use

- Powerful motor and high torque, allowing for efficient milling operations

- Durable construction and high-quality materials for long-lasting performance

- A versatile machine capable of handling a wide range of materials and applications

Cons

- Limited power and capability compared to larger milling machines

- Smaller worktable size restricts the size of projects that can be undertaken

2.Sunwin Metal Mini Milling Machine

The SUNWIN Metal Mini Milling Machine is a compact and versatile tool for precision milling tasks. Its durable metal construction offers stability and durability for long-term use. This mini milling machine is perfect for hobbyists, DIY enthusiasts, and small-scale workshops. It has a powerful motor and a variable speed control, allowing users to adjust the milling speed according to their needs.

The machine also features a precision spindle for accurate milling and a wide range of adjustable settings for different milling depths and angles. Whether you need to mill small parts, create intricate designs, or perform precision drilling, the SUNWIN Metal Mini Milling Machine is a reliable and efficient choice.

Features And Specifications

With its lightweight construction, weighing just 7.71 pounds, this milling machine provides a convenient and portable solution for those seeking flexibility in their work environment. Whether you need to reposition it for better access or store it away after use, its manageable weight ensures effortless mobility. Its compact dimensions of 9.8 x 9.8 x 5.9 inches further enhance its user-friendly design, making it suitable for use in various spaces and easy to accommodate in any workshop or storage area.

Equipped with precise clamping capabilities, this milling machine offers a versatile range of applications. With clamping dimensions ranging from one to six millimetres, it provides the flexibility to work with different workpiece sizes and shapes. The included vice clamp, with a size of 1.1 inches, adds to the machine’s adaptability by securely holding the workpiece during milling operations.

Pros

- Compact and portable design

- Ideal for small-scale milling projects

- Versatile and can work with various materials

- Easy to use and control

Cons

- Limited power and capability compared to larger milling machines

- Limited worktable size, which may restrict the size of projects that can be worked on

3.SHOP FOX M1110 Mill And Drill

The SHOP FOX M1110 Mill and Drill is a versatile machine that combines milling and drilling capabilities. Its powerful motor and adjustable speed settings can tackle many tasks. The M1110 features a sturdy construction, ensuring stability and accuracy during operation.

It has a spacious worktable and various useful features, such as a digital readout and a fine feed control. Whether you need to mill, drill, or both, the SHOP FOX M1110 is a reliable choice to help you accomplish your machining projects precisely and efficiently.

Features And Specifications

The SHOP FOX M1110 Mill and Drill is a versatile machine offering various features and specifications. It is designed to provide precision and efficiency in milling and drilling operations. This mill and drill machine can handle various materials and projects with a powerful motor and robust construction. It offers a drilling capacity of up to 1 inch and a milling capacity of up to 2 inches, allowing for versatility in size and scope.

Additionally, it features variable speed control, enabling users to adjust the speed according to their specific needs. The SHOP FOX M1110 Mill and Drill is a reliable tool for professional and hobbyist machinists, offering the performance and durability required for various applications.

Pros

- Versatile machine that combines milling and drilling capabilities

- Robust construction and high-quality materials ensure durability

- Offers precise and accurate results for various machining tasks

- It comes with adjustable speed settings for enhanced control and efficiency

Cons

- Limited power and capacity compared to larger mill and drill machines

- Not suitable for heavy-duty milling or drilling tasks

4.Klutch Mini Milling Machine

The Klutch Mini Milling Machine is a compact, versatile tool for precision milling operations. It is equipped with a powerful motor and a variable speed control, allowing users to adjust the milling speed according to their needs.

With a solid construction and precise machining capability, this machine is ideal for hobbyists, small workshops, and DIY enthusiasts. It offers various cutting options and can handle various materials, including metal, plastic, and wood. The Klutch Mini Milling Machine is a reliable and efficient tool that delivers high-quality results in a compact package.

Features And Specifications

The Klutch Mini Milling Machine is a compact, versatile tool for precision milling operations. It features a powerful 3/4 HP motor that delivers consistent performance and allows a wide range of machining materials. The machine has a variable speed control, allowing users to adjust the spindle speed according to their needs and requirements. With a maximum drilling capacity of 1/2 inch and a milling capacity of 5/8 inch, it provides ample room for various machining tasks.

The Klutch Mini Milling Machine also boasts a sturdy construction with a cast iron column and base, ensuring stability and durability during operation. Additionally, it comes equipped with a digital depth display, making it easier to monitor and control the milling depth. Whether you are a DIY enthusiast or a professional machinist, this machine offers precision and reliability for your milling needs.

Pros

- Compact and portable design

- Suitable for small-scale milling projects

- Versatile and can handle a variety of materials

- Easy to set up and operate

Cons

- Limited power and capability compared to larger milling machines

- Limited workspace and size capacity, limiting the size of projects

5.Grizzly G0781 3/4 Hp Mill/Drill

The Grizzly G0781 3/4 hp Mill/Drill is a versatile machine that combines milling and drilling capabilities. Its powerful 3/4 horsepower motor can handle various tasks in a workshop or garage setting. The mill/drill features a sturdy construction and a compact design, making it suitable for small to medium-sized projects. It offers a range of drilling and milling speeds, allowing for precision and control. The Grizzly G0781 is a reliable and efficient tool popular among DIY enthusiasts and professionals.

Features And Specifications

The Grizzly G0781 3/4 hp Mill/Drill is a powerful and versatile machine that combines milling and drilling capabilities. A 3/4 horsepower motor provides ample power for a wide range of projects. The mill/drill features a precision-ground cast iron table that ensures operation stability and accuracy. It also comes equipped with a spindle speed range of 140-2,470 RPM, allowing precise cutting speed control.

The Grizzly G0781 has a 2-speed gearbox, allowing users to choose between high torque or high-speed settings. It has a maximum drilling capacity of 1 inch and a milling capacity of 2 inches. With its robust construction and reliable performance, the Grizzly G0781 is an excellent choice for professional and hobbyist machinists.

Pros

- Powerful 3/4 hp motor for efficient milling and drilling

- A versatile machine capable of both milling and drilling operations

- Solid construction for durability and stability during use

- Adjustable speed settings for precise control over the machining milling process

Cons

- Limited power with only 3/4 hp

- May struggle with heavy-duty milling and drilling tasks

6.Sherline Deluxe 5400 Series Mill

The Sherline Deluxe 5400 Series Mill is a high-quality milling machine designed for precision machining tasks. It offers a compact and user-friendly design, making it suitable for hobbyists and professionals. With its robust construction and precise controls, this mill allows for accurate cutting, drilling, and shaping of various materials, including metals, plastics, and wood.

The Sherline Deluxe 5400 Series Mill also has a range of optional accessories and attachments, providing versatile capabilities to meet different machining needs. Whether you are working on small-scale projects or intricate designs, this mill is a reliable and efficient tool to achieve precise results.

Features And Specifications

The Sherline Deluxe 5400 Series Mill is a high-quality milling machine that offers a range of features and specifications suitable for various machining tasks. It has a powerful 90V DC motor that provides smooth and consistent operation.

The mill has a working area of 10 inches in length and 6 inches in width, allowing for precise and accurate milling. It also features adjustable zero handwheels, allowing for easy and precise movement of the axes. The Sherline Deluxe 5400 Series Mill includes a variety of accessories, such as a 3-axis digital readout, a rotary table, and a milling vice, making it a versatile and efficient tool for any machining project.

Pros

- Compact and space-saving design

- Precise and accurate milling capabilities

- Versatile and can handle a wide range of materials

- Easy to set up and operate

Cons

- Limited milling capacity compared to larger industrial mills

- Slower milling speed due to smaller motor

Tips For Setting Up And Operating A Benchtop Milling Machine

equipping your workshop with the right tools, a benchtop milling machine is an essential addition. This versatile machine allows you to perform a wide range of precision machining tasks, making it indispensable for hobbyists and professionals. With numerous options available in the market, it is important to consider the features and capabilities of different benchtop milling machines before deciding. Here are Tips for Setting Up and Operating a Benchtop Milling Machine:

- Familiarize yourself with the machine’s manual and safety guidelines before operating it.

- Ensure the machine is properly levelled and secured to the workbench or surface.

- Use appropriate personal protective equipment (PPE) such as safety glasses and ear protection.

- Select the right cutting tools and secure them properly in the machine’s spindle.

- Take measurements and plan your machining operations carefully to achieve desired results.

- Start with low cutting speeds and gradually increase them as needed.

- Regularly check and maintain the machine’s lubrication system to ensure smooth operation.

Maintenance And Care Of Benchtop Milling Machines

One popular option is a benchtop milling machine with a digital readout (DRO) system. This technology provides accurate and real-time measurements, ensuring precise machining results. Additionally, machines with variable speed control allow you to adjust the cutting speed according to the material being worked on, ensuring optimal performance and extending tool life. Here are the Maintenance and Care of Benchtop Milling Machines:

- Regularly clean the milling machine to remove debris and dust buildup

- Lubricate moving parts according to the manufacturer’s instructions to ensure smooth operation

- Check and tighten all bolts and screws to ensure stability and prevent any potential accidents

- Monitor the condition of cutting tools and replace them when necessary

- Regularly inspect the machine for any signs of wear or damage and address any issues promptly

- Follow proper safety protocols while operating the machine to prevent accidents

Conclusion

A benchtop milling machine can be valuable to any workshop for professional use or personal projects. It is important to prioritize power, precision, and versatility to make the most efficient and effective choice for your projects. With a range of options available, it’s important to carefully consider your specific needs and budget before purchasing.

Whichever machine you choose, following proper safety precautions and maintenance procedures is important to ensure optimal performance. With the right benchtop milling machine, you can take your machining capabilities to the next level and achieve precise and efficient project results.

FAQ

1.What Are The Three 3 Basic Types Of Milling Machines?

The three basic types of milling machines are vertical milling machines, horizontal milling machines, and universal milling machines. Vertical milling machines have a vertical spindle axis, allowing the cutting tool to move up and down along the z-axis.

2.What Is A Benchtop Milling Machine?

A benchtop milling machine is a compact hobby machine designed to be placed on a workbench or table. It is a smaller version of a full-sized milling machine commonly used for hobbyist or small-scale machining projects.

3.What Is The Alternative To A Milling Machine?

The alternative to a milling machine is a lathe machine. A lathe is a drilling machine tool that rotates a workpiece on its axis to perform various operations such as cutting, drilling, and shaping.

4.What Is The Use Of A Milling Machine In The Workshop?

A milling machine is a versatile tool used in workshops for cutting, shaping, and drilling various materials. It can create precise and complex shapes, contours, and patterns on metal, wood, plastic, and other materials.

5.Which Type Of Milling Machine Is Used Mostly In General Workshops?

The type of machine used mostly in general workshops is the vertical milling machine shop. It is versatile and commonly used for machining operations such as drilling, facing, and milling slots or grooves.