Milling machines are an essential tool in the manufacturing and machining industry. They are handy for shaping and cutting various Softer materials such as metal, wood, and plastic with precision and accuracy.

These machines have existed for centuries, but with the advancement of technology, various types of milling machines are now available in the market. Each type of milling machine has unique features and functions, making them suitable for different purposes. Understanding the different types of milling machines is crucial in choosing the right one for a specific project.

Here, we will explore the various types of milling machines, their features, and their uses. We will also discuss the advantages and disadvantages of each type, providing a comprehensive guide to help you make an informed decision.

The History And Evolution Of Milling Machines

Milling machines have a rich history that dates back to the 19th century. The milling concept originated with rotary cutter files, manually operated to shape and cut metal. However, it was not until the 1860s that Eli Whitney developed the first true milling plain milling machine. This machine utilized interchangeable parts and revolutionized manufacturing processes.

Over the years, milling machines have undergone significant advancements and improvements. The introduction of computer numerical control (CNC) technology in the 20th century brought about a new era in milling machine capabilities. CNC milling machines are now highly automated and can precisely execute complex machining operations quickly and accurately.

The Basics Of Milling Operations

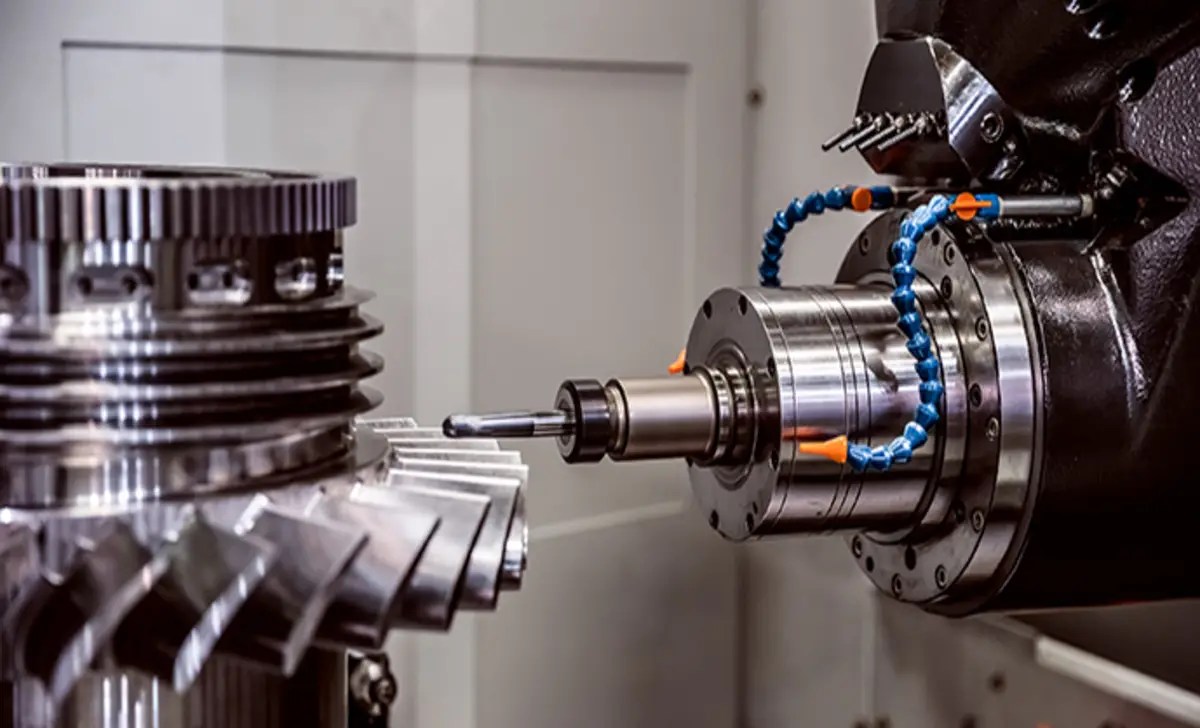

Milling operations are an essential part of the machining process, which involves removing material from a workpiece to shape it into specific forms. The cutting tool, usually a milling cutter, removes material as it rotates against the workpiece. This process enables the machine to create flat surface finishes and complex shapes by precisely sculpting the workpiece.

The cutting edges of the milling cutter remove material from the workpiece as it spins. Depending on the specific milling operation required, these cutting edges can be straight or shaped. By adjusting the speed, feed rate, and depth of cut, machinists have control over the amount of material removed, leading to greater precision in the final product.

Vertical Milling Machines

Vertical milling machines are a commonly handy type of milling machine, with the spindle axis positioned vertically. The vertical column supports the machine’s structure and provides stability during milling. The spindle head, located at the top of the vertical column, houses the cutting tool and controls its movement.

Vertical milling machines are highly versatile, allowing drilling, grooving, and milling processes. The vertical axis of these machines enables the cutting tool to move vertically, making them suitable for machining operations requiring cutting depth adjustments. This type of milling machine is often handy in the automotive industry, where precision machining is essential.

Horizontal Milling Machines

As the name suggests, horizontal milling machines have the spindle axis situated horizontally. The horizontal spindle holds the cutting tool, which can move in different directions to shape the workpiece. This type of milling machine is commonly used for large diameter milling and mass production, such as manufacturing automotive parts.

The horizontal spindle allows the cutting tool to remove material along the horizontal axis, resulting in efficient milling operations. The workpiece is clamped onto the machine’s table, and the horizontal spindle’s rotation, combined with the tool’s cutting edges, shapes the workpiece precisely. Horizontal milling machines are widely used in various industries thanks to their high precision and versatility.

Universal Milling Machines

Universal milling machines are popular for their versatility and can perform various milling operations. These machines can mill in different directions, making them highly flexible for drilling, milling, and boring processes. Universal milling machines are particularly useful when complex machining operations are required and specific shapes must be obtained.

The tool axis of universal milling machines can rotate, allowing for different machining operations with precision. This rotation and specific attachments enable the machine to cater to various manufacturing processes. Whether milling, drilling, or boring, universal milling machines provide the required shape versatility for specific machining requirements.

Turret Milling Machines

Turret milling machines are vertical milling machines that feature a turret, which houses the machine tools. This turret enables precision milling operations, holding multiple cutting tools at different angles. Turret milling machines are often used in industries that require high precision, such as aerospace and automotive manufacturing.

Turret machines excel at manual milling operations, allowing operators to perform complex machining tasks accurately. The turret’s ability to hold various tools ensures flexibility and precision during milling operations. With a closer look at the workpiece, machinists can achieve high-precision milling, producing superior-quality products.

Bed Milling Machines

Bed milling machines are known for their rigid structure, providing stability during milling operations. These machines feature a horizontal axis saddle, the bed, to support the workpiece and machine tools. Bed milling machines are popular for large diameter milling and high-precision work, making them ideal for mass production.

The machine tools, including the milling cutter, are attached to the horizontal axis saddle, allowing for controlled movement during machining. The large diameter milling capabilities of bed milling machines make them suitable for various industries where high precision and efficiency are essential. These machines excel at drilling, lathe work, and precise milling operations.

CNC Milling Machines

CNC milling machines, or Computer Numerical Control milling machines, are revolutionizing the manufacturing industry. These machines operate through numerical control, using pre-programmed instructions to control the milling process. CNC mills provide high-precision machining capabilities, making them a crucial tool in mass-production industries.

By utilizing CNC control, milling operations can be automated, ensuring consistent precision in the final product. CNC milling machines are widely used in various manufacturing processes, from machining complex shapes to mass production of standardized parts. The rotating spindle axes, high-precision cutter, and arbors work together to achieve accurate milling results required by industry standards.

Mini Milling Machines

For small-scale operations and precision work, mini-milling machines are the tool of choice. These compact machines are ideal for drilling, machining, and small-scale milling. Despite their smaller size, mini-milling machines maintain the precision required for various industries.

Mini-milling machines are popular among hobbyists, DIY enthusiasts, and small workshops. They allow users to create custom parts, prototypes, and intricate designs with precision. The closer look provided by manual operation gives machinists better control over the milling process, resulting in high-quality and accurate work.

Choosing The Right Milling Machine For Your Needs

Choosing the right milling machine for your specific requirements is crucial for optimal manufacturing processes. Consider the type of milling machine that suits your needs, considering various industries and typical manufacturing processes. Assess the required shape versatility, precision, and machining operations.

Different industries and projects call for specific types of milling machines. For example, automotive manufacturers may require vertical milling machines for precision machining, while large-scale production industries may rely on horizontal milling machines for mass production. Carefully evaluate the machine’s capability for complex shapes, high-precision milling, drilling, lathe work, and other machining operations to ensure optimal productivity.

Maintenance And Care Of Milling Machines

Milling machines are versatile and essential tools commonly used in various industries, including manufacturing, engineering, and metalworking. These machines are crucial in shaping and cutting materials to precise specifications. Milling machines have a rotating cutter that removes material from the workpiece, producing a smooth and accurate finish. Here are the Maintenance and Care of Milling Machines:

- Regularly clean the milling machine to remove any debris or dust.

- Lubricate the moving parts of the machine to ensure smooth operation.

- Check and tighten any loose bolts or screws.

- Inspect and replace any worn-out or damaged parts.

- Calibrate the machine periodically to maintain accuracy.

- Follow proper safety guidelines while operating the machine.

- Store the milling machine in a clean and dry environment when not in use.

- Keep a record of maintenance tasks and schedule regular inspections.

Troubleshooting Common Issues With Milling Machines

One of the significant advantages of milling machines is their ability to perform a wide range of operations. Milling machines offer unmatched versatility, from simple tasks like drilling holes and cutting slots to complex operations such as contouring and threading. This makes them an indispensable asset for businesses looking to streamline their production processes and enhance overall efficiency. Here are Troubleshooting Common Issues with Milling Machines:

- Check for power supply issues.

- Ensure proper lubrication of machine parts.

- Verify correct tooling and tool holder specifications

- Inspect for any loose or damaged belts or pulleys

- Calibrate and adjust machine settings as needed

- Clean and remove any debris or chips from the machine

- Troubleshoot and replace any faulty sensors or components

Conclusion

Understanding the different types of milling machines is crucial for selecting the right one for your specific needs. Whether it’s vertical milling machines, horizontal milling machines, universal milling machines, turret milling machines, bed milling machines, CNC machines, or mini milling machines, each type has unique features and advantages.

Consider factors such as the workpiece’s size, the operation’s complexity, and the precision required when choosing a milling machine. By selecting the appropriate machine, you can maximize productivity and achieve excellent results in your milling operations. So, take the time to research and evaluate your options to make an informed decision.

Frequently Asked Questions

1.What Are The Types Of Milling Machines?

Ans: Common types of milling machines include vertical, horizontal, and universal. CNC milling machines are widely used. Other specialized types include bed-type, knee-type, and planer-type. The choice depends on specific project requirements.

2.What Are The 7 Basic Types Of Machine Tools?

Ans: The 7 basic types of machine tools include milling machines, lathes, drill presses, grinding machines, saws, boring mills, and CNC machines. Milling machines are specifically used for cutting and shaping metal and other Harder materials, while lathes are mainly used for turning and shaping cylindrical objects.

3.How Many Types Of Operations Are There In A Milling Machine?

Ans: There are several types of operations in a milling machine, including face milling, end milling, slot milling, drilling, and boring. Each operation serves a specific purpose and involves different cutting tools and techniques.

4.What Are The Five Parts Of The Milling Machine?

Ans: The five main parts of a milling machine are the base, column, knee, saddle, and head. The base provides a stable foundation for the machine, while the column supports the head and the vertical movement of the machine.

5.Who Are Milling Machines For?

Ans: Machinists, engineers, and manufacturers use milling machines in various automotive, aerospace, and construction industries.