Imagine crafting intricate metal pieces with perfect precision. Sounds like a dream, right? This vision becomes a reality with the best metal lathe for precision turning. But what makes a lathe the best? Is it speed, power, or ease of use? These machines can transform a simple piece of metal into detailed art.

Think about a toy car. It needs tiny, exact parts to work well. A good metal lathe can help you make those parts easily. Some people even say using a lathe is like having magic in your hands. You can create anything from small gears to beautiful sculptures!

Finding the right lathe is key. You want one that fits your needs. Whether you’re a hobbyist or a professional, having the best metal lathe can change your projects forever. So, let’s dive into what makes a metal lathe truly great for precision turning.

The Best Metal Lathe For Precision Turning You Must Consider

Choosing the best metal lathe for precision turning can be exciting and challenging. You’ll learn about essential features like accuracy, ease of use, and durability. Imagine making perfect, smooth cuts in metal! Good lathes help you create detailed parts for your projects. Whether you’re a hobbyist or professional, the right lathe can transform your ideas into reality. Discover how the best options can enhance your craftsmanship and achieve great results!

Understanding Precision Turning

Definition and importance of precision turning in metalworking. Common applications and industries that benefit from precision lathes.

Precision turning is like a superhero in metalworking. It makes sure that every tiny detail is perfect. This process creates parts that fit together like puzzle pieces. Industries like automotive, aerospace, and medical gear depend on it to work smoothly. Imagine a car engine running perfectly because of well-turned metal parts! Below are some common applications:

| Industry | Application |

|---|---|

| Automotive | Engine components |

| Aerospace | Aircraft parts |

| Medical | Tools and implants |

Simply put, precision turning is crucial! Without it, our technology might be as useful as a chocolate teapot! So, next time you think of metal lathes, smile knowing they help create the amazing things we use every day.

Key Features to Look for in a Precision Lathe

Spindle speed and range for various materials. Bed length and width for different project sizes. Control systems: CNC vs. manual operations.

Picking a precision lathe is like choosing a pizza topping—everyone has their favorite! First, check the spindle speed and range. Different materials need different speeds. A lathe with flexible options can handle anything from soft wood to stubborn metal without losing its cool.

Next, consider bed length and width. You don’t want to start a big project only to find your lathe is too small. Think of it as choosing a bed; a longer one gives you more room to stretch out!

Lastly, think about control systems. Do you prefer the hands-on fun of a manual operation or the precision of CNC? Both have their perks—like choosing whether to toss your salad or let a robot do it for you!

| Feature | Importance |

|---|---|

| Spindle Speed | Handles different materials |

| Bed Length | Accommodates various project sizes |

| Control System | Manual gives direct control; CNC offers precision |

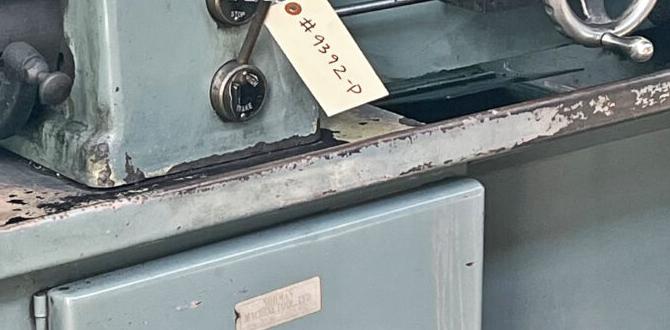

Best Models of Precision Lathes on the Market

Detailed reviews of top models, including specifications and use cases. Pros and cons of each model to guide buyer decisions.

Finding the right precision lathe can be tough. Here are some of the top models available:

- Model A: Ideal for small workshops. It has a 12-inch swing and variable speed. Pros: easy to use, compact. Cons: limited power.

- Model B: Perfect for beginners. Features include a 14-inch swing and digital readout. Pros: accurate measurements, sturdy build. Cons: heavier to lift.

- Model C: Great for professionals. Offers a 16-inch swing and high-speed capabilities. Pros: powerful, versatile. Cons: more expensive.

Each model has its strengths and weaknesses. Consider your needs before making a choice.

What should I look for in a precision lathe?

Look for size, power, and features that meet your projects. Accurate measurements and ease of use can also make a big difference.

Budget Considerations for Buying a Metal Lathe

Price range for different types of precision lathes. Tips for finding the best value without compromising quality.

Buying a metal lathe can be fun but tricky. Lathes vary in price. Basic models can cost around $300. More advanced ones may run up to $2,000 or more. To find great value, consider these tips:

- Research different brands.

- Look for sales or discounts.

- Read customer reviews for quality insights.

Remember, spending less doesn’t mean losing quality. Find a balance to get the best metal lathe for precision turning.

What is the average price range for metal lathes?

The average price for metal lathes is $300 to $2,000. Entry-level lathes are cheaper, while high-end models cost more.

Tips for getting value:

- Check warranty options.

- Compare specs closely.

Maintenance Tips for Longevity and Performance

Regular maintenance tasks and schedules. Troubleshooting common issues and solutions.

To keep your metal lathe happy, follow a simple maintenance schedule. Clean it regularly and check for loose parts. Lubricate moving pieces monthly, like giving it a nice spa day. If something goes wrong, don’t panic! Common issues include weird noises or a stuck spindle. Most times, a little oil or a wrench can do the trick. Here’s a quick table to help:

| Task | Frequency | Possible Issue & Solution |

|---|---|---|

| Clean | Weekly | Dust build-up > Use compressed air |

| Lubricate | Monthly | Stiff movement > Add oil |

| Inspect parts | Quarterly | Loose parts > Tighten bolts |

Following these tips will boost your lathe’s performance. Remember, happy lathe, happy you!

Working Safely with Metal Lathes

Essential safety gear and equipment. Best practices for safe operation and risk mitigation.

Safety is key when using metal lathes. Start by wearing essential safety gear like goggles, gloves, and ear protection. This keeps you safe from flying debris and loud sounds.

- Use a dust mask to avoid breathing in metal particles.

- Keep your workspace clean to prevent slips and trips.

- Always check the machine before starting to ensure everything is in place.

Follow these best practices for safe operation:

- Stay focused and avoid distractions.

- Never wear loose clothing that could get caught in the machine.

- Use proper tools for the job to minimize risks.

By using the best metal lathe for precision turning and following safety steps, you can work confidently.

What safety gear is needed for metal lathes?

You need the right safety gear to protect yourself. Use goggles to protect your eyes, earplugs for loud noise, and gloves for hand safety. A dust mask is also smart to keep your lungs safe from metal dust.

Best practices for using metal lathes safely

- Always wear your safety gear.

- Check the machine before each use.

- Don’t rush; take your time with tasks.

Resources for Learning Precision Turning Techniques

Recommended books and online courses. Helpful forums and communities for metalworking enthusiasts.

Learning precision turning can be exciting! Here are some resources to help you get started:

- Books: Look for titles like “Machining Fundamentals” and “The Metal Lathe” for in-depth knowledge.

- Online Courses: Websites such as Udemy and Coursera offer great classes on metalworking.

- Forums: Join communities like Reddit’s metalworking subreddits to share tips and ask questions.

- Local Workshops: Check for nearby classes where you can learn hands-on skills.

These resources make learning fun and help you master your skills in no time!

What are the best resources for learning precision turning?

Books and online courses provide a great start. Online forums connect you with fellow enthusiasts.

Conclusion

In conclusion, the best metal lathe for precision turning helps you create accurate and smooth parts. Look for features like solid construction, precise controls, and reliable power. Starting with a trusted brand ensures quality and support. Now, do some research and check out reviews to find the right lathe for your needs. Happy turning!

FAQs

What Key Features Should I Look For In A Metal Lathe To Ensure Precision Turning?

When looking for a metal lathe, check for a strong bed. A solid bed helps keep the machine steady. Look for a good motor for smooth spinning. You also want precise controls to make exact cuts. Finally, think about the size; it should fit your projects.

Are There Specific Brands Or Models Of Metal Lathes That Are Highly Regarded For Their Precision?

Yes, some brands of metal lathes are known for being very precise. For example, brands like Haas and Sherline make great machines. They help you cut metal accurately. You can trust these brands for good quality!

How Does The Size And Weight Of A Metal Lathe Affect Its Precision In Turning Operations?

A heavy and big metal lathe is usually more stable. This means it won’t shake much while working. Less shaking helps us make exact cuts on the metal. A small and light lathe can wiggle and might not produce perfect pieces. So, size and weight help us make things more accurately.

What Is The Importance Of Spindle Accuracy And Rigidity In Achieving Precision On A Metal Lathe?

Spindle accuracy and rigidity are very important when using a metal lathe. The spindle holds the tool in place while you work. If it is accurate, the tool cuts exactly where you want it to. If it is rigid, it won’t move around while you’re cutting. This means your pieces will be made correctly and look great!

How Can Additional Tooling And Accessories Enhance The Precision Capabilities Of A Metal Lathe?

Using extra tools and accessories makes a metal lathe more precise when you work. For example, special cutting tools can help you shape metal better. A measuring tool lets you check sizes closely, so everything fits perfectly. You can also use attachments that hold the metal more securely. With these additions, your projects will turn out more accurately and look nicer!