Have you ever struggled with dull lathe tools? It can be frustrating when you want to create something amazing, but your tools just won’t cooperate. Finding the best sharpening system for lathe tools can make all the difference. Imagine how much easier your woodworking projects could be with sharp, precise tools!

Many woodworkers wonder which sharpening systems work best. Some people swear by wet grinders, while others prefer manual sharpeners. A fun fact is that a sharp tool is not only safer but also helps you finish your work faster! This makes the search for the right system even more important.

In this article, we will explore the best sharpening system for lathe tools. You’ll learn what to look for and how to choose the one that fits your needs. Ready to discover the key to sharper, more efficient lathe tools? Let’s dive in!

Discover The Best Sharpening System For Lathe Tools Today

Finding the best sharpening system for lathe tools can feel tricky. A great system saves time and ensures smooth cuts. Do you want sharp tools that last? A reliable sharpening system can help you work faster and safer. Many options exist, like diamond wheels or bench grinders. Each type offers unique benefits. Knowing your needs makes choosing easier. Did you know sharp tools can reduce fatigue? You’ll enjoy lathe work even more with the right sharpening system!

Types of Sharpening Systems

Manual vs. automatic sharpening systems. Pros and cons of various sharpening systems (wet, dry, and belt).

Sharpening systems come in two flavors: manual and automatic. Manual systems need a little elbow grease; they’re like riding a bike without training wheels. They offer control but can be tough on tired hands. On the flip side, automatic systems do the work for you, making it feel like you’re a wizard casting spells on dull tools!

There are different types of sharpening tools: wet, dry, and belt. Wet systems are great for keeping tools cool, but they can be messy—bring a towel! Dry systems are neat and quick, but they might heat up your tools more than a hot summer day. Belt systems combine speed and flexibility, but they can be tricky to master. Here’s a quick look:

| Type | Pros | Cons |

|---|---|---|

| Wet | Cool sharpening | Messy |

| Dry | Quick and clean | Can overheat tools |

| Belt | Fast and flexible | Tricky to use |

Choosing the best sharpening system for lathe tools can make your crafting adventures fun and safe. Happy sharpening!

Key Features to Look For

Grinding wheel type and grit size. Adjustable angles and tool rests for different tools.

Choosing the right sharpening system can be exciting! Here are some key features to consider:

- Grinding Wheel Type: Look for wheels made of high-quality materials. They should fit your sharpening needs.

- Grit Size: Smaller grit sizes create a smooth edge, while larger sizes remove more metal quickly.

- Adjustable Angles: Systems that allow angle adjustments will help you sharpen different tools better.

- Tool Rests: Good rests support your tools securely while sharpening.

These features can make sharpening your lathe tools easier and more effective!

What grit size is best for lathe tools?

For lathe tools, a grit size of 120 to 220 works well. This range helps create sharp edges without too much effort.

Why are adjustable angles important?

Adjustable angles let you sharpen tools at the correct position. This ensures perfect edges for various tasks.

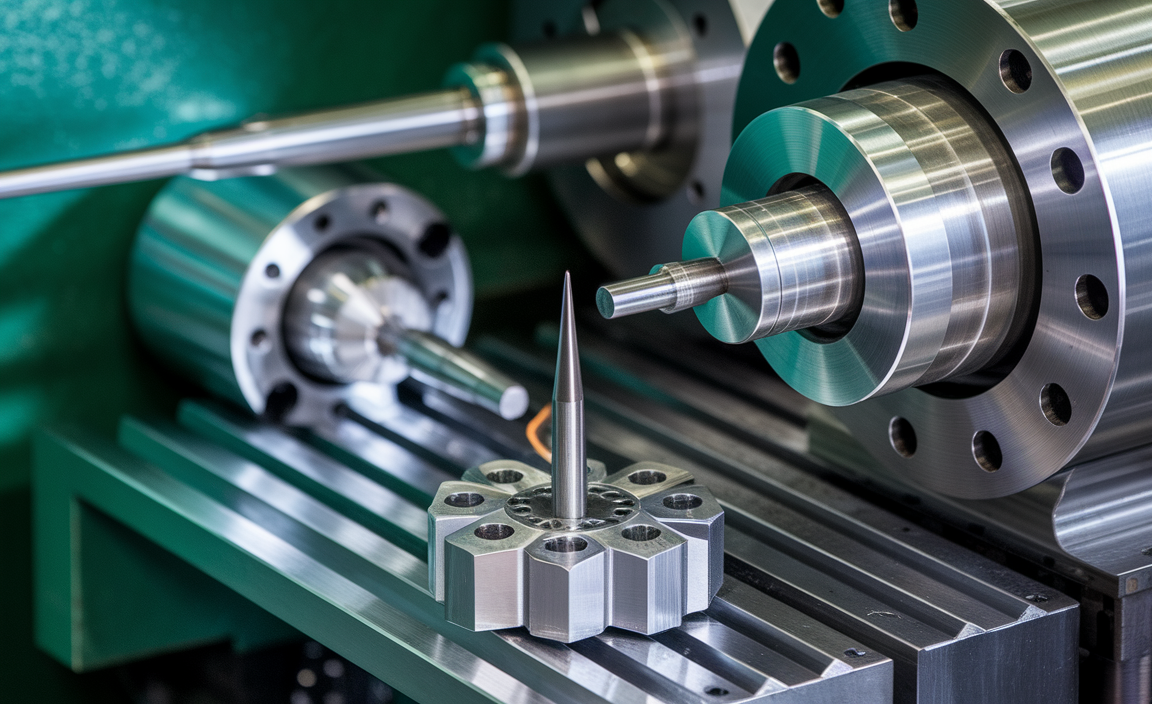

Top Sharpening Systems Reviewed

Detailed comparison of leading sharpening systems available in the market. User ratings and feedback on each system. There are many sharpening systems on the market, and they can be quite different. Some are fancy and high-tech, while others are simple and effective. Let’s break down a few popular ones. These systems have user ratings that show what people really think. It turns out, many love the ease of use and quality results. Here’s a quick comparison that’ll make your head spin faster than a lathe!

| Sharpening System | User Rating | Pros | Cons |

|---|---|---|---|

| System A | 4.5/5 | Easy to use, great results | Pricey! |

| System B | 4.0/5 | Compact, portable | Limited features |

| System C | 4.8/5 | Durable, versatile | Takes time to learn |

Whether you’re a pro or just starting, user feedback shines a light on what works best. Remember, a sharp tool makes for a happy woodworker!

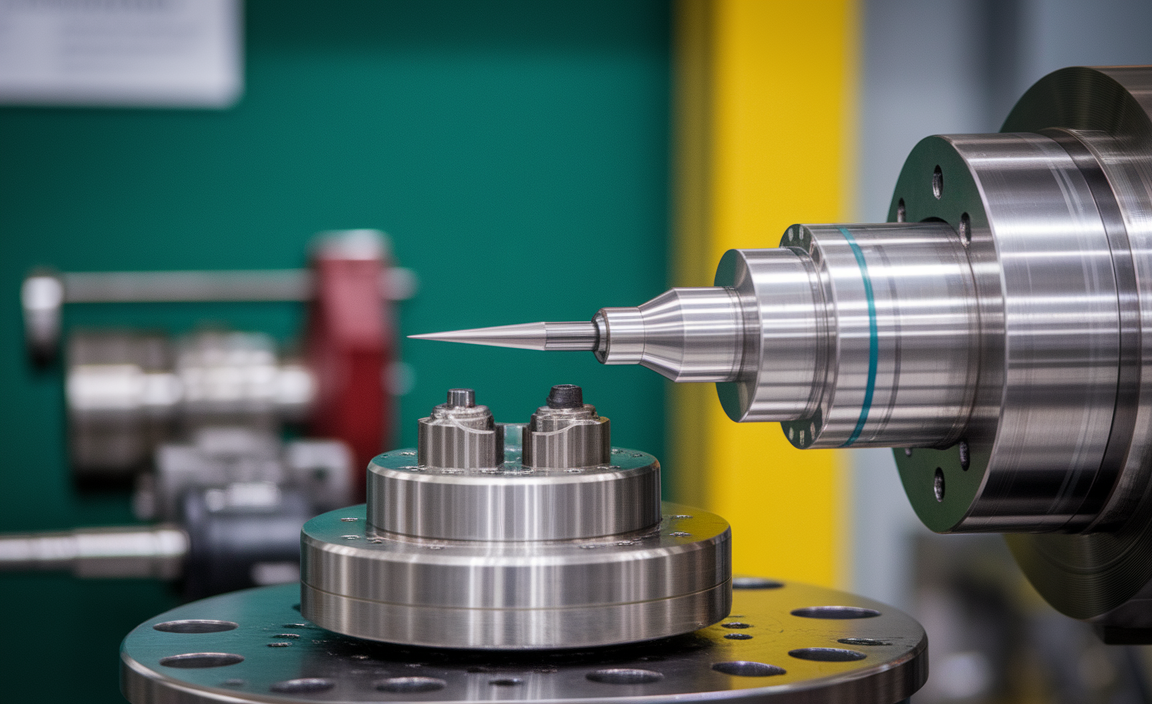

Step-by-Step Guide to Sharpening Lathe Tools

Preparation and setup of the sharpening system. Techniques for effective sharpening of different tool types. To sharpen your lathe tools like a pro, start by setting up your sharpening system properly. Make sure it’s on a sturdy surface—no wobbly tables, please! Gather your tools and wear safety gear; you don’t want to be known as “that person with the funny-looking bandage!” Next, understand each tool type. For gouges and chisels, use a slow-speed grinder. For turning tools, a sharpening jig will work wonders. It’s like giving your tools a spa day!

| Tool Type | Sharpening Technique |

|---|---|

| Gouges | Slow-speed grinding |

| Chisels | Sharpening jig |

| Turning tools | Angle adjustment |

And remember: A sharp tool is a happy tool. It cuts cleaner and lasts longer. Your projects deserve the best!

Common Mistakes to Avoid

Typical errors in the sharpening process that can damage tools. Tips to enhance blade longevity and performance.

Many people make mistakes while sharpening lathe tools. These errors can harm tools and reduce their lifespan. Overheating is a common problem. It can ruin the metal. Using the wrong angle can make cutting less effective. To keep your tools performing well, avoid these tips:

- Use slow, even pressure when sharpening.

- Cool the tool often to prevent heat damage.

- Follow the manufacturer’s guide for angles.

- Sharpen regularly to maintain sharpness.

What are typical sharpening errors?

Common errors in sharpening tools include overheating, incorrect angles, and excessive pressure. These mistakes can damage the tools and decrease their effectiveness.

Maintaining Your Sharpening System

Routine maintenance tasks for longevity and effectiveness. Identifying signs that your sharpening system needs attention. Taking care of your sharpening system is key for good results. Regular tasks help keep it running well. Check the system often for wear and tear. If you notice any unusual sounds or poor sharpening, it’s time to look closer. Follow these steps for proper care:

- Clean the sharpening stones or wheels often.

- Check for cracks or chips on the edges.

- Ensure the motor runs smoothly and quietly.

- Lubricate moving parts regularly.

Doing this will help your tools stay sharp and last longer.

Why is routine maintenance important?

Routine maintenance helps your sharpening system work like new, ensuring it lasts longer and sharpens effectively.

Expert Recommendations and Tips

Insights from professional woodworkers on sharpening practices. Recommended accessories and additional tools for optimal results.

Many professional woodworkers suggest using a sharpening system that fits your needs. It’s like finding the perfect pair of shoes—comfort matters! Some swear by diamond stones, while others prefer water stones for their smooth finish.

Extra tools can help too! A honing guide can ensure a straight edge and keep the blade happy. Don’t forget to check out the trusty strop for that final touch. It’s like a spa day for your tools!

| Tool | Why Use It? |

|---|---|

| Diamond Stone | Sharpens quickly and lasts long. |

| Water Stone | Gives a fine, smooth edge. |

| Honing Guide | Keeps angles precise. |

| Strop | Perfect for that extra polish. |

Keep your tools happy, and they will return the favor. As they say, “A sharp tool is a happy tool!”

Conclusion

In conclusion, choosing the best sharpening system for lathe tools is essential for smooth results. Look for systems that are easy to use and offer precise angles. Remember, regular sharpening keeps your tools effective and safe. Explore options and read reviews to find the right fit for you. Keep improving your skills and enjoy crafting with sharp tools!

FAQs

Sure! Here Are Five Related Questions On The Topic Of The Best Sharpening System For Lathe Tools:

Sure! If you want the best sharpening system for lathe tools, think about what you need. Some systems use wheels, while others use belts. You should choose one that fits your tools and is easy to use. Always remember to keep safety in mind while sharpening!

Sure! Please ask your question, and I will be happy to answer it in a simple way!

What Are The Key Features To Look For In A Sharpening System Specifically Designed For Lathe Tools?

When choosing a sharpening system for lathe tools, look for a good presence of a steady grinding wheel. You want it to keep tools balanced while sharpening. Check if it has an adjustable rest so you can position the tool easily. A clear guide for angles helps you sharpen to the right shapes. Lastly, a good safety feature protects you while you work.

How Does The Choice Of Sharpening Method (E.G., Whetstone, Honing Wheel, Or Grinding Machine) Impact The Performance Of Lathe Tools?

The way you sharpen lathe tools affects how well they work. A whetstone can create a sharp edge slowly but gives good control. A honing wheel sharpens faster, making it great for quick jobs. A grinding machine is quick and powerful, but it might remove too much metal. Choosing the right method helps your tools cut better and last longer.

Are There Specific Sharpening Systems That Are More Suitable For Beginners Versus Experienced Woodturners?

Yes, some sharpening systems are better for beginners. They are easy to use and help you learn quickly. For example, a simple honing jig can be great for starting. Experienced woodturners might prefer more advanced tools that give them greater control. As you get better, you can choose systems that let you sharpen faster and more precisely.

What Maintenance And Care Practices Should I Follow To Ensure My Sharpening System Stays Effective And Prolongs The Life Of My Lathe Tools?

To keep your sharpening system working well, clean it after each use. Wipe down the parts to remove dust and grime. Check for any damage, like cracks or rust, and fix them if needed. Store your sharpening tools in a dry place to prevent rust. Lastly, sharpen your lathe tools regularly to keep them in good shape!

How Do Different Materials (E.G., Carbide Vs. High-Speed Steel) Affect The Selection Of A Sharpening System For Lathe Tools?

Different materials need different sharpening tools. Carbide is hard, so you need a special sharpener for it. High-speed steel is softer, so you can use regular sharpeners. You have to pick the right one, so your tools stay sharp for a long time. Choosing the wrong sharpener can make your tools dull or even damage them.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of The Best Sharpening System For Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! If you want the best sharpening system for lathe tools, think about what you need. Some systems use wheels, while others use belts. You should choose one that fits your tools and is easy to use. Always remember to keep safety in mind while sharpening!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I will be happy to answer it in a simple way!”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Sharpening System Specifically Designed For Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a sharpening system for lathe tools, look for a good presence of a steady grinding wheel. You want it to keep tools balanced while sharpening. Check if it has an adjustable rest so you can position the tool easily. A clear guide for angles helps you sharpen to the right shapes. Lastly, a good safety feature protects you while you work.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Sharpening Method (E.G., Whetstone, Honing Wheel, Or Grinding Machine) Impact The Performance Of Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The way you sharpen lathe tools affects how well they work. A whetstone can create a sharp edge slowly but gives good control. A honing wheel sharpens faster, making it great for quick jobs. A grinding machine is quick and powerful, but it might remove too much metal. Choosing the right method helps your tools cut better and last longer.”}},{“@type”: “Question”,”name”: “Are There Specific Sharpening Systems That Are More Suitable For Beginners Versus Experienced Woodturners?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some sharpening systems are better for beginners. They are easy to use and help you learn quickly. For example, a simple honing jig can be great for starting. Experienced woodturners might prefer more advanced tools that give them greater control. As you get better, you can choose systems that let you sharpen faster and more precisely.”}},{“@type”: “Question”,”name”: “What Maintenance And Care Practices Should I Follow To Ensure My Sharpening System Stays Effective And Prolongs The Life Of My Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your sharpening system working well, clean it after each use. Wipe down the parts to remove dust and grime. Check for any damage, like cracks or rust, and fix them if needed. Store your sharpening tools in a dry place to prevent rust. Lastly, sharpen your lathe tools regularly to keep them in good shape!”}},{“@type”: “Question”,”name”: “How Do Different Materials (E.G., Carbide Vs. High-Speed Steel) Affect The Selection Of A Sharpening System For Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials need different sharpening tools. Carbide is hard, so you need a special sharpener for it. High-speed steel is softer, so you can use regular sharpeners. You have to pick the right one, so your tools stay sharp for a long time. Choosing the wrong sharpener can make your tools dull or even damage them.”}}]}