Have you ever wondered how machines cut shapes into metal or wood? The answer often lies in the way they move. This movement is called tool paths. When making ramping cuts, choosing the best tool paths is very important. A bad path can ruin a project.

Imagine trying to slice through a big cake. If you don’t use the right knife, the cake could fall apart. Just like that cake, your material needs the right path for a clean cut.

Did you know some tool paths can speed up work and make cuts smoother? Discovering the best tool paths for ramping cuts can save time and effort. It can also lead to a better finish on your project. So, which paths are the best? Let’s dig into the world of ramping cuts and find out.

Best Tool Paths for Ramping Cuts

Choosing the best tool paths for ramping cuts can make a big difference in your project. Ramping cuts allow for smoother transitions and can reduce tool wear. A good path involves gradual angles, promoting better chip removal and minimizing strain. Have you noticed how a steep ramp can lead to problems? By using the right tool path, you can enhance precision and efficiency. So, next time you design a cut, think about how your path choice makes a real impact!

Understanding Ramping Cuts

Definition and significance of ramping cuts in machining. Comparison with traditional cutting methods.

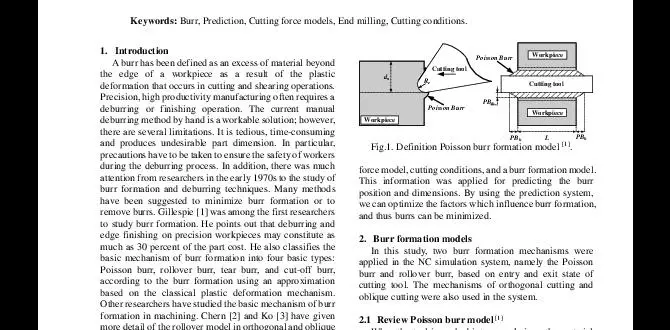

Ramping cuts are special ways to shape materials in machining. They create smooth slopes instead of straight edges. This method is important because it reduces stress on the tool and the workpiece. It also allows for faster movements. Compared to traditional cutting methods, ramping cuts are often more efficient. They help in creating clean finishes and less chip buildup. Overall, ramping cuts can improve the speed and quality of machining jobs.

What are ramping cuts in machining?

Ramping cuts help make cleaner shapes by using angled cuts instead of sharp drops. These cuts work well with many materials, making them a smart choice for machinists.

Benefits of Ramping Cuts:

- Less tool wear

- Improved cut quality

- Faster machining time

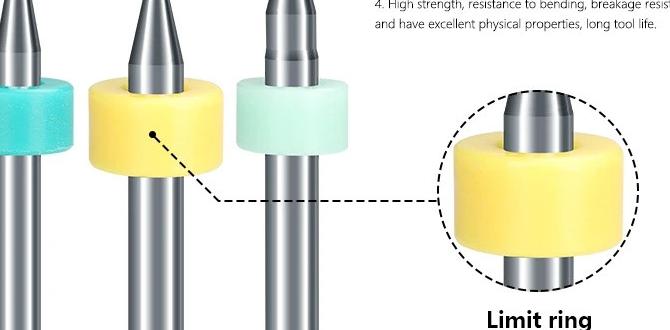

Key Factors Influencing Tool Path Selection

Material type and its impact on tool paths. Machine capabilities and their relevance to ramping cuts.

Choosing the right tool path for ramping cuts matters a lot. Different materials can change how the tools work. For example, harder materials need different paths than softer ones. Machine capabilities also play a big role. If a machine is strong, it can handle tough cuts better. Here are some key factors:

- Material Type: Harder materials often need steep ramping.

- Machine Strength: Strong machines can support complex paths.

- Tool Type: The shape and size of the tool affect path choices.

What is the impact of material type on tool paths?

The material type greatly affects tool paths. Hard materials need different methods than soft ones. Softer materials may allow for more flexible paths.

How do machine capabilities influence ramping cuts?

Machine capabilities greatly impact ramping cuts. A more powerful machine can make cuts with smoother transitions and complex shapes. This leads to better results in various materials.

Types of Tool Paths for Ramping Cuts

Linear ramping paths: benefits and limitations. Circular ramping paths: when to use this option.

Ramping cuts use special tool paths to make smooth moves. One common type is the linear ramping path. It’s simple to follow and works well for many projects. However, it can create a sharp transition that may be risky. On the other hand, circular ramping paths add a gentle curve. Use this option when you need to avoid sudden drops or when your machine needs a softer touch. A little extra roundness can keep your tools—and your parts—happier!

| Tool Path Type | Benefits | Limitations |

|---|---|---|

| Linear Ramping | Simple and effective | Sharp transitions |

| Circular Ramping | Gentle moves | Slower cutting speed |

Optimizing Tool Paths for Efficiency and Precision

Techniques for minimizing cycle time during ramping cuts. Adjusting feed rates and depths of cut for optimal performance.

Efficient ramping cuts can save both time and resources. Start by adjusting feed rates; slower feeds are great for precision, while faster feeds speed things up. Tweak the depth of cut too—sometimes going deep is good, but shallow cuts can make the tool last longer. It’s all about finding balance! Think of it as a dance: too fast and you trip, but too slow is just boring.

| Technique | Benefit |

|---|---|

| Adjusting Feed Rates | Maximizes Efficiency |

| Tweaking Cut Depths | Improves Tool Life |

Common Mistakes to Avoid in Ramping Cuts

Typical pitfalls in tool path selection and execution. How to troubleshoot issues that arise during ramping operations.

Avoiding common mistakes in tool path selection is crucial for smooth ramping cuts. Here are key pitfalls to be aware of:

- Choosing the wrong speed or feed rate can damage tools.

- Neglecting to check for material type may lead to errors.

- Failing to account for tool wear can affect cut quality.

If problems arise during ramping, troubleshoot with these steps:

- Inspect the tool path for any abrupt angles.

- Adjust speeds gradually and avoid sudden changes.

- Examine the machine settings to ensure they are correct.

What are the common mistakes made during ramping cuts?

Some typical mistakes include using the wrong tool speed and not checking the material type. These errors can cause problems, leading to poor cuts and tool damage. Always double-check settings to avoid these issues.

Case Studies: Successful Implementations of Ramping Cuts

Realworld examples highlighting effective ramping cut strategies. Analysis of outcomes and lessons learned from these case studies.

Looking at real examples can be a real eye-opener! One company used ramping cuts in their machining process and saw a 30% boost in efficiency. They chose smooth tool paths which helped reduce vibration. Another manufacturer reported less tool wear with a clever ramp design, which saved them money in replacements. Lessons learned? Keep it smooth, and remember: a happy tool is a long-lasting tool! Check out the table below for more details.

| Company | Strategy Used | Outcome | Lessons Learned |

|---|---|---|---|

| Company A | Smooth ramping cuts | 30% efficiency boost | Keep it smooth! |

| Company B | Clever ramp design | Less tool wear | Happy tools last longer! |

Future Trends in Ramping Cut Techniques

Innovations on the horizon in ramping cut methodologies. The role of automation and AI in enhancing machining processes.

Exciting changes are coming to ramping cut techniques! Soon, we’ll see innovations that make cutting smoother and even more precise. Automation and AI are stepping in, sharpening our processes and making machines work more efficiently—like having a smart buddy who knows all the tricks. Imagine robots that help us cut without getting tired! Who wouldn’t want a tireless helper in the workshop? Plus, these trendy tools might even save us some precious time. Let’s take a peek at how the future is shaping up.

| Trend | Description |

|---|---|

| Smart Tools | Machines that learn from mistakes and improve over time. |

| Automation | Robots doing the boring stuff while we sip lemonade! |

| AI Insights | AI helps in finding the best cuts every time. |

Conclusion

In summary, choosing the best tool paths for ramping cuts is essential for smooth machining. You want to prioritize efficiency and accuracy. Experiment with different angles and speeds to see what works for your projects. Don’t hesitate to explore further resources or tutorials. They can help improve your skills and make your cuts even better!

FAQs

What Factors Should Be Considered When Selecting The Best Tool Path Strategy For Ramping Cuts In Cnc Machining?

When picking a tool path for ramping cuts in CNC (Computer Numerical Control) machining, you should think about several things. First, look at the shape of the part you’re making. This helps you decide how fast the tool can move. Next, consider the material you’re cutting. Softer materials may need a different path than harder ones. Lastly, think about how much material needs to be removed. This helps you choose the best way to get the job done quickly and safely.

How Do Different Ramping Angles Affect Tool Wear And The Overall Integrity Of The Cut?

When you change the ramping angle, it can change how fast a tool wears out. A steeper angle might make the tool work harder, which can cause it to wear down faster. If the angle is too shallow, the cut may not be as clean. A good angle helps keep the tool sharp and makes better cuts.

What Are The Advantages Of Using Helical Ramping Versus Linear Ramping In Milling Operations?

Helical ramping is better than linear ramping for milling because it cuts smoothly. You can move into the material without sudden stops or jerks. This means less wear on the tools we use. It also makes a nicer finish on the pieces we’re working on. Overall, it helps us work faster and more safely.

How Can Simulation Software Help In Optimizing Tool Paths For Ramping Cuts Before Actual Machining?

Simulation software lets us see how machines move before we start cutting. It helps us plan the best paths for the tools. We can test different ways to cut without wasting materials. This way, we can avoid mistakes and make the process faster. Using the software helps us save time and money in real life!

What Are Common Mistakes To Avoid When Programming Tool Paths For Ramping Cuts In Cnc Machines?

When programming tool paths for ramping cuts in CNC machines, avoid these mistakes. First, don’t set the ramp angle too steep. This can make the tool break or move poorly. Also, check the speed of the tool; going too fast is bad. Finally, make sure the machine is ready and set up correctly before starting.