Have you ever struggled with dull tools while working on your wood projects? It’s frustrating, isn’t it? Choosing the best wood lathe tool sharpening system can change that. A sharp tool makes woodturning smooth and fun. Imagine effortlessly shaping wood into beautiful items.

Did you know that a sharp tool can be the difference between a great project and a disappointing one? A good sharpening system helps you keep your tools ready for action. This can save you time and effort. When your tools are sharp, they work better and last longer.

In this article, we will explore different sharpening systems. We’ll look at what makes them the best. You’ll find tips and insights to help you choose the right one for your needs. So, are you ready to discover the best wood lathe tool sharpening system for your workshop?

The Best Wood Lathe Tool Sharpening System For Precision

Best Wood Lathe Tool Sharpening System

Choosing the right wood lathe tool sharpening system can transform your woodworking experience. A good sharpening system keeps tools sharp, which makes turning wood easier and more enjoyable. You’ll learn about various honing jigs and sharpening stones that best fit your needs. Did you know a sharp chisel can make carving a breeze? With the proper maintenance, tools last longer, saving you time and money. Discover how simple sharpening steps lead to perfect, smooth cuts!Understanding Wood Lathe Tool Sharpening

Importance of sharpening wood lathe tools. Common mistakes in tool sharpening.Sharpening wood lathe tools is very important. Sharp tools make carving easier and safer. They help you create smoother cuts and improve your projects.

Some common mistakes in sharpening include:

- Not using the right angle. A wrong angle can damage the tool.

- Sharpening too much. This can wear down the tool faster.

- Using dull stones. Always keep your stones clean and sharp.

By avoiding these mistakes, you’ll keep your tools in good shape and get better results.

What is the effect of dull wood lathe tools?

Dull tools can cause accidents and make your work harder. They can also create rough surfaces that need more time to fix.

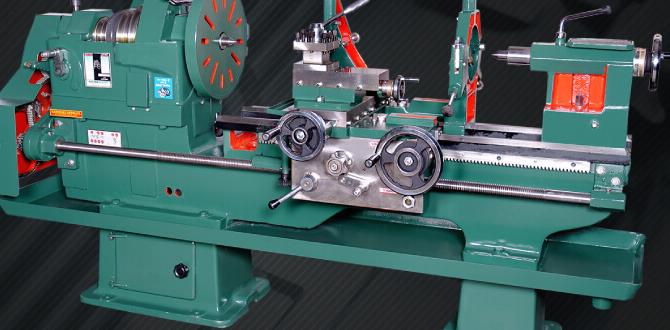

Types of Wood Lathe Tool Sharpening Systems

Manual sharpening systems: pros and cons. Electric sharpening systems: benefits and drawbacks.When it comes to sharpening wood lathe tools, you’ll find two main types: manual and electric systems. Manual sharpening is like using a trusty old spoon—it’s reliable! You can control the angle and pressure, but it needs practice to master. It can be slow, and no one enjoys blisters! On the flip side, electric sharpeners are speedy and offer consistent results. However, they might cost more and can dull tools if used too much. Both have their perks and quirks!

| Type | Pros | Cons |

|---|---|---|

| Manual | Affordable, full control | Time-consuming, requires skill |

| Electric | Fast, consistent results | Expensive, risk of over-sharpening |

Choose wisely, and your tools will be sharper than your best jokes!

Key Features to Look for in Sharpening Systems

Grinding wheel specifications and types. Adjustable rests and angles.When choosing a sharpening system, look for specific features to make your tasks easier. Here are two key points:

- Grinding Wheel Specifications: Wider wheels can grind faster. Choose wheels made from materials like aluminum oxide for durability.

- Adjustable Rests and Angles: You want rests that move easily. Adjustable angles give you precise control for better sharpening.

These features improve performance and help keep your tools sharp longer.

What are the best grinding wheel types for sharpening?

Aluminum oxide and ceramic wheels are the best choices. They both last long and sharpen quickly.

Top Wood Lathe Tool Sharpening Systems Reviewed

Indepth review of popular brands and models. Comparison of performance, price, and user satisfaction.When it comes to sharpening your wood lathe tools, many brands stand out. Each model has its strengths, like how some are faster and others are user-friendly. Let’s compare a few popular options based on performance, price, and user satisfaction. Remember, a happy tool owner is a sharper tool owner!

| Model | Performance | Price | User Satisfaction |

|---|---|---|---|

| Model A | Fast & Accurate | $100 | ★★★★☆ |

| Model B | Very Easy to Use | $85 | ★★★★★ |

| Model C | Good Balance | $120 | ★★★★☆☆ |

Overall, many users agree that finding the right tool sharpening system can make all the difference. After all, dull tools don’t just annoy you; they make you unhappy woodworkers! So, let’s dig deeper into these reviews and find out which one suits your needs best.

Step-by-Step Guide to Sharpening Wood Lathe Tools

Preparation and setup for sharpening. Techniques for different tool types (gouges, chisel, etc.).Before sharpening your wood lathe tools, gather your supplies. Ensure you have a sharpening system, safety goggles, and perhaps a coffee to stay awake! Set your tools up on a flat surface to avoid any disasters—no one wants a flying chisel at lunch! For different tools, like gouges and chisels, use specific techniques. A slight angle for chisels, and a round motion for gouges works wonders. Remember, a happy tool is a sharp tool!

| Tool Type | Sharpening Technique |

|---|---|

| Gouges | Round motion to maintain curve |

| Chisels | Slight angle for a fine edge |

Maintenance Tips for Sharpening Tools

Cleaning and care of sharpening systems. Lifespan and replacement indicators for parts.Keeping your sharpening system in top shape is key for successful tool maintenance. First, give it a good clean. Dirt and grime can really dull your tools—like a sad party clown! Regularly check for worn parts, too. If a wheel looks uneven, it’s time for a change. Remember, a smooth cut makes wood happy!

| Part | Replacement Indicator |

|---|---|

| Grinding Wheel | If it’s uneven or worn down more than 1/8 inch |

| Drive Belt | If you hear squeaks or it feels loose |

| Motor | If it struggles to start or runs hot |

Cost Analysis of Different Sharpening Systems

Budgetfriendly options for hobbyists. Premium systems for professional use.There are many sharpening systems for wood lathes. Prices can vary widely. Hobbyists looking for budget-friendly options can find systems for around $50 to $150. These tools often have basic features, but they get the job done well. For professionals, premium systems can range from $200 to over $500. These advanced tools offer more features and better precision. Choosing the right system depends on your skill level and needs.

What are budget-friendly options for hobbyists?

Budget-friendly sharpening systems are available starting at $50. They are great for beginners. These tools might be simple, but they work effectively for hobby projects.

Premium tools for professionals

- Prices start at $200.

- Offer advanced features for precision.

- Designed for regular use in workshops.

In conclusion, your choice of system should match your experience and budget. There is a solution for everyone!

Frequently Asked Questions about Wood Lathe Tool Sharpening

Common queries and expert answers. Troubleshooting issues with sharpening techniques.Many people have questions about sharpening wood lathe tools. How often should I sharpen my tools? It’s best to sharpen them before each use. What are common sharpening mistakes? Not using the right angle is a big one.

- Check your tool for chips.

- Make sure your sharpening system is stable.

Conclusion

In conclusion, finding the best wood lathe tool sharpening system is essential for every woodworker. A good system keeps your tools sharp and makes turning easier. Look for features like ease of use and durability. We recommend researching brands and reading reviews. Try out different systems to see what works best for you. Happy woodworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of The Best Wood Lathe Tool Sharpening Systems:Sure! When sharpening wood lathe tools, you want to use a good system. A popular choice is a slow-speed grinder. It helps keep tools cool while sharpening. You can also use honing guides to get a perfect angle. Remember, sharp tools make wood turning easier and more fun!

Sure! Please provide the question you would like me to answer.

What Are The Key Features To Look For In A Wood Lathe Tool Sharpening System?When you look for a wood lathe tool sharpening system, check for three key features. First, see if it has adjustable speeds. This helps you sharpen tools better. Second, make sure it has good safety features to keep you safe while sharpening. Finally, look for a system that is easy to use and set up. This way, you can sharpen your tools quickly and easily!

How Do Different Sharpening Methods (E.G., Grinding Vs. Honing) Affect The Performance Of Wood Lathe Tools?Different sharpening methods can change how well wood lathe tools work. Grinding makes a new edge by removing a lot of metal quickly. This is great for fixing dull tools but can make them hot and lose strength. Honing, on the other hand, carefully smooths the edge without removing much metal. It helps tools stay sharp longer and cuts better.

What Are The Advantages Of Using A Sharpening Jig Versus Freehand Sharpening For Lathe Tools?Using a sharpening jig helps you sharpen tools more evenly. It keeps your hands steady, so you make fewer mistakes. You can also set the angle, which means your tools will be sharp every time. This makes it easier and faster for you to work on your projects. Overall, a sharpening jig helps you get better results without much effort.

Are There Any Specific Sharpening Systems Recommended For Beginners In Woodturning?Yes, beginners in woodturning can use simple sharpening systems. A good choice is a bench grinder with a sharpening jig. This tool helps you hold your tools steady while you sharpen them. You can also try a hand-held sharpening stone, which is easy to use. Remember to practice and take your time!

How Can I Maintain The Longevity And Effectiveness Of My Wood Lathe Tools Through Proper Sharpening Techniques?To keep your wood lathe tools working well, you should sharpen them regularly. Use a sharpening stone or a file to keep the edges nice and sharp. Always check the angle of the blade to make sure it cuts smoothly. After sharpening, clean your tools to remove any dust or shavings. Finally, store them in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of The Best Wood Lathe Tool Sharpening Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When sharpening wood lathe tools, you want to use a good system. A popular choice is a slow-speed grinder. It helps keep tools cool while sharpening. You can also use honing guides to get a perfect angle. Remember, sharp tools make wood turning easier and more fun!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Wood Lathe Tool Sharpening System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you look for a wood lathe tool sharpening system, check for three key features. First, see if it has adjustable speeds. This helps you sharpen tools better. Second, make sure it has good safety features to keep you safe while sharpening. Finally, look for a system that is easy to use and set up. This way, you can sharpen your tools quickly and easily!”}},{“@type”: “Question”,”name”: “How Do Different Sharpening Methods (E.G., Grinding Vs. Honing) Affect The Performance Of Wood Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different sharpening methods can change how well wood lathe tools work. Grinding makes a new edge by removing a lot of metal quickly. This is great for fixing dull tools but can make them hot and lose strength. Honing, on the other hand, carefully smooths the edge without removing much metal. It helps tools stay sharp longer and cuts better.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Sharpening Jig Versus Freehand Sharpening For Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a sharpening jig helps you sharpen tools more evenly. It keeps your hands steady, so you make fewer mistakes. You can also set the angle, which means your tools will be sharp every time. This makes it easier and faster for you to work on your projects. Overall, a sharpening jig helps you get better results without much effort.”}},{“@type”: “Question”,”name”: “Are There Any Specific Sharpening Systems Recommended For Beginners In Woodturning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, beginners in woodturning can use simple sharpening systems. A good choice is a bench grinder with a sharpening jig. This tool helps you hold your tools steady while you sharpen them. You can also try a hand-held sharpening stone, which is easy to use. Remember to practice and take your time!”}},{“@type”: “Question”,”name”: “How Can I Maintain The Longevity And Effectiveness Of My Wood Lathe Tools Through Proper Sharpening Techniques?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your wood lathe tools working well, you should sharpen them regularly. Use a sharpening stone or a file to keep the edges nice and sharp. Always check the angle of the blade to make sure it cuts smoothly. After sharpening, clean your tools to remove any dust or shavings. Finally, store them in a dry place to prevent rust.”}}]}