Quick Summary

A boring bar for a lathe is a tool used to enlarge and smooth existing holes in your workpiece accurately. This guide breaks down what it is, how to choose one, and the essential steps for safe and effective use on your lathe, making complex internal machining simple for beginners.

Welcome to Lathe Hub! I’m Daniel Bates, and I’m passionate about making machining accessible to everyone. If you’ve ever looked at the inside of a metal part and thought, “How do I make that clean and precise?” you’re in the right place. Today, we’re diving into a seemingly simple, but incredibly important tool: the boring bar. It’s the key to creating accurate, smooth internal diameters on your lathe. Don’t worry if it sounds intimidating; we’ll break it down step-by-step, just like we always do here at Lathe Hub.

What Exactly is a Boring Bar for a Lathe?

Think of a boring bar as a specialized cutting tool that works from the inside out. When you need to enlarge a pre-drilled hole in a workpiece securely held on your lathe, a boring bar is your go-to solution. Unlike external turning tools that shape the outside of your material, a boring bar’s cutting edge goes into the hole. Its primary job is to create a hole of a specific, accurate diameter and finish with a smooth surface. This is crucial for parts that need to fit precisely with other components, like bearings or shafts.

The name itself can be a bit misleading. While “boring” sounds like drilling, in machining terms, it specifically refers to enlarging an already existing hole. Drilling creates a new hole from solid material. So, a boring bar isn’t for starting a hole; it’s for refining and sizing one that’s already there.

Why Use a Boring Bar? The Advantages

You might be wondering why you can’t just use a standard drill bit or an end mill to enlarge a hole. While those tools have their place, a boring bar offers distinct advantages, especially when precision and finish quality are paramount:

- Accuracy and Precision: Boring bars are designed for high-precision work. They allow you to achieve very tight tolerances on hole diameters, which is vital for parts that need to fit together perfectly.

- Superior Surface Finish: Unlike drilling, which can sometimes leave a rough finish, boring with a properly set up boring bar results in a much smoother internal surface. This reduces friction and wear in moving parts.

- Enlarging Existing Holes: They are specifically made for enlarging pre-existing holes, whether those were drilled, cast, or punched. This is a common requirement in manufacturing and repair.

- Reduced Workpiece Stress: Boring generally exerts less stress on the workpiece compared to methods like reaming or aggressive drilling on thin-walled parts. This helps prevent distortion.

- Capability for Deep Holes: Long boring bars are available, allowing you to bore holes in the internal diameters of long or deep parts, which can be challenging with other tools.

- Versatility: With different types of boring bars and cutting inserts, you can machine various materials and achieve different finishes.

Types of Boring Bars

Not all boring bars are created equal! They come in different styles designed for specific tasks and materials. Understanding these types will help you choose the right one for your project.

Solid Boring Bars

These are typically made from a single piece of high-speed steel (HSS) or carbide. They are simple, robust, and excellent for general-purpose boring. Carbide versions are harder and can handle higher speeds and tougher materials.

Carbide Shank Bars

These bars feature a carbide shank with an insert held in a pocket. The carbide shank provides rigidity and damping of vibrations, leading to better surface finishes and allowing for higher cutting speeds. They are ideal for achieving a high-quality finish on a variety of materials.

Steel Shank Bars with Inserts

Similar to carbide shank bars but made with a steel body, these hold replaceable carbide or HSS inserts. They are often more economical than solid carbide bars and offer a good balance of performance and cost. The replaceable inserts mean you can easily swap out worn or chipped cutting edges.

Vibration-Dampening Bars

For very deep holes or when working with materials prone to vibration, specialized boring bars with built-in dampening mechanisms are available. These can significantly improve surface finish by reducing chatter. While often expensive, they are indispensable for certain high-precision applications.

Adjustable Boring Heads

These are not technically boring bars themselves but are common companions. An adjustable boring head mounts to a rigid bar (the boring bar) and allows for fine-tuning of the boring diameter. They are incredibly useful for setting precise diameters without needing to physically adjust the bar itself.

Key Components of a Boring Bar Setup

To use a boring bar effectively, you need to understand its main parts and how they work together:

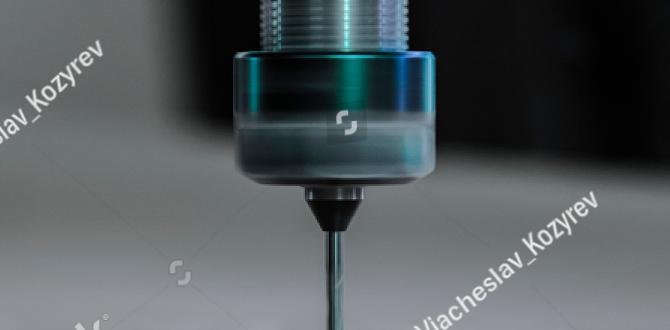

- The Bar Itself: This is the main shank of the tool that extends into the workpiece. Its rigidity and diameter are critical for stability.

- The Cutting Insert or Tip: This is the part that actually removes material. It can be brazed-on (like on some solid HSS bars) or a replaceable carbide insert held in place by a screw or clamp.

- The Holder/Shank: This is the portion of the boring bar that secures into the lathe’s tool post. It needs to be rigid and accurately aligned.

- Clamping Mechanism: This is what holds the insert securely in the bar. It could be a grub screw, a wedge, or a clamp.

Choosing the Right Boring Bar for Your Lathe Project

Selecting the correct boring bar is crucial for success. Here are the main factors to consider:

Material of the Workpiece

Soft Metals (Aluminum, Brass): You can often get away with HSS or standard carbide inserts. Speeds can be higher.

Harder Metals (Steel, Stainless Steel): Use tougher carbide inserts, and consider vibration-dampening bars for deeper bores. Lower speeds and appropriate feeds are essential.

Exotic Materials: May require specialized inserts (e.g., ceramic, CBN) and specific speeds/feeds.

Hole Diameter and Depth

Small Diameter Holes (Under 1/2 inch): Require slender bars. Vibration can be a major issue, so rigidity is key. Consider bars with smaller insert sizes.

Large Diameter Holes: Generally easier as they allow for more robust bars.

Deep Holes: Longer bars are needed, and vibration becomes a significant challenge. Vibration-dampening bars are often necessary for consistent results. A good rule of thumb:

The length of the boring bar that extends beyond the tool holder should ideally not exceed 3-4 times its diameter to maintain rigidity. For deeper bores, you might need specialized bars or techniques. For more on tool overhang and rigidity, consider resources from organizations like the National Institute of Standards and Technology (NIST), which provides extensive research on manufacturing processes.

Required Accuracy and Surface Finish

For very tight tolerances and a mirror-smooth finish, you’ll want a high-quality carbide bar, potentially a vibration-dampening one, and sharp, appropriate inserts. For less critical applications, a solid HSS bar might suffice.

Lathe Size and Tool Post Capacity

Ensure the shank of the boring bar fits securely in your lathe’s tool post and that your lathe has the power and rigidity to handle the cutting forces. A small hobby lathe might struggle with a large, heavy-duty boring bar.

Essential Tools and Setup for Boring

Before you start boring, gather these items:

- The Chosen Boring Bar: Make sure it’s the right size and type for your job.

- Indexable Inserts: Have a few spares. Ensure they are the correct geometry and coating for your material.

- Tool Holder: The piece that holds the boring bar shank in the lathe’s tool post.

- Lathe Chuck: To firmly hold your workpiece.

- Tailstock (Optional but Recommended): For longer workpieces or when extra support is needed, a drill chuck or live center in the tailstock can help stabilize the workpiece.

- Dial Indicator or Caliper: For precise measurement.

- Safety Glasses: Absolutely non-negotiable.

- Machinist’s Gloves (Optional, use with caution): For handling rough stock, but remove when operating the lathe. Better yet, keep hands clear.

- Magnifier or Magnifying Lamp: To inspect inserts and cuts.

- Cutting Fluid/Lubricant: Essential for most metal boring to cool the tool and workpiece, and to flush away chips.

Setting up your boring bar is just as important as choosing it. Here’s a common method:

- Mount Your Workpiece: Securely mount the part you want to bore in the lathe chuck. Ensure it’s centered.

- Insert the Boring Bar: Place the boring bar shank into its holder and then mount the holder in the lathe’s tool post.

- Align the Boring Bar: This is CRITICAL. The boring bar must be perfectly centered with the spindle axis. Use a height gauge or carefully place a solid parallel across the lathe centers and adjust the tool post until the boring bar is exactly at the same height. Many machinists use a dial indicator to confirm perfect alignment. The tip of the boring bar should be precisely at the center height of the lathe.

- Secure the Insert: If you have a removable insert, carefully install it according to the manufacturer’s instructions. Ensure it’s properly seated and tightened. A loose insert is extremely dangerous.

- Position the Tool: Move the boring bar into the pre-drilled hole, ensuring the cutting edge is just inside the hole’s edge.

Step-by-Step Guide: Boring a Hole on Your Lathe

Now, let’s get to the actual cutting. Safety first, always!

Step 1: Preparation and Safety Check

Put on your safety glasses. Ensure the workpiece is securely clamped. Check that the boring bar is firmly seated in its holder and the holder is tight in the tool post. Make sure no tools or rags are draped precariously near the moving parts of the lathe.

Step 2: Set Your Lathe Speeds and Feeds

This depends heavily on your material, insert type, and boring bar size. As a general starting point for steel with a carbide insert:

- Speed: Lower RPMs, often in the range of 100-300 RPM for larger diameters, and up to 500-800 RPM for smaller diameters. Always consult insert manufacturer charts. For example, Sandvik Coromant, a leading tooling manufacturer, provides extensive data on their website, which you can find via a search for their technical data.

- Feed Rate: Start conservatively. For general boring, a feed rate of 0.004 to 0.010 inches per revolution (IPR) is common. Too fast can break inserts or cause chatter; too slow can rub and overheat.

Step 3: Apply Cutting Fluid

Start the flow of cutting fluid to the cutting area. This is vital for cooling, lubrication, and chip evacuation, especially when working with metals.

Step 4: Make the First Cut (The “Soak”)

With the lathe spinning at your chosen speed and feed, carefully advance the boring bar into the hole. The goal here is to take a light cut to establish the correct diameter. Engage the feed (either longitudinal or cross-feed, depending on your setup) and let the tool do its work. Watch and listen for any signs of chatter or excessive force.

Step 5: Measure and Adjust

Once you’ve bored a reasonable length (or to your desired depth), retract the boring bar. Stop the lathe. Use your caliper or internal micrometer to carefully measure the diameter of the bored hole. Compare this to your target dimension. You will likely need to make adjustments:

- If the hole is too small: The boring bar’s cutting edge needs to be positioned slightly further out. If using an adjustable boring head, adjust its dial. If using a fixed-style bar, you might need to slightly reposition the boring bar in the tool post (though this risks messing up center height) or, more commonly, make very fine adjustments to the cross-slide dial and take another light pass.

- If the hole is too large: You’ve gone too deep with the cut. You may need to start again with a new workpiece or accept the oversized dimension. Precision boring often involves taking very light “finishing” passes.

Step 6: Take Finishing Passes

Once you are close to the target diameter, take very light finishing passes. This means reducing the depth of cut significantly (e.g., to 0.005 – 0.010 inches) and possibly adjusting the feed rate. These passes refine the surface finish and bring the diameter to its final, precise size.

Step 7: Final Measurement and Inspection

After the last finishing pass, stop the lathe, retract the boring bar, and carefully measure the hole again. Ensure it meets your specifications for diameter and surface finish.

Common Boring Problems and How to Fix Them

Even experienced machinists run into issues. Here are some common problems and their solutions:

| Problem | Cause | Solution |

|---|---|---|

| Chatter/Vibration |

|

|

| Poor Surface Finish |

|

|

| Oversized Hole |

|

|

| Undersized Hole |

|

|

Boring Bar Maintenance

Just like any tool, your boring bar needs a little care to keep performing its best:

- Cleanliness: After each use, clean the bar and its holder to remove chips and coolant residue. A brass brush is good for this.

- Insert Inspection: Routinely check inserts for any signs of wear, chipping, or dullness. Replace them before they cause problems.

- Storage: Store boring bars in a dry place, ideally in a protective case or holder to prevent damage to the tip or shank.

- Shank Care: Ensure the shank that goes into the tool post is clean and free of burrs so it seats properly.

Safety First: Never Compromise!

Machining involves inherent risks, and boring is no exception. Always remember:

- Eye Protection: Always wear safety glasses. A full face shield is even better for added protection.

- Clear Workspace: Keep your lathe area clean and free of obstructions.

- No Loose Clothing or Jewelry: These can get caught in rotating machinery.

- Secure Workholding: A loose workpiece can become a dangerous projectile.

- Sharp Tools ONLY: Dull tools require more force, increase the risk of breakage, and generate excess heat.

- Understand Your Machine: Know how to operate your lathe’s emergency stop.

- Chip Management: Use a chip brush or shop vacuum to remove chips, not your hands.

- Never Reach Over a Running Spindle: Always ensure the machine is stopped before making adjustments or measurements.

For comprehensive safety guidelines, you can refer to resources from organizations like the Occupational Safety and Health Administration (OSHA