Are you thinking about diving into the world of metalworking? Perhaps you want to create cool projects or fix things around the house. Metal lathes are fantastic tools that can help you achieve amazing results. But how do you choose the right metal lathe cutting tools? It can be tricky!

Many people get confused by the variety of tools available. Each one has its own purpose and use. Did you know that some cutting tools are better for specific jobs? Understanding these differences can save you time and money.

Imagine starting a project, only to find out you don’t have the right tool. It can be frustrating! That’s why we created this buying guide. We will break down everything you need to know about metal lathe cutting tools. By the end, you’ll feel confident in making your choice.

So, let’s get started! The right metal lathe cutting tools are just a few tips away.

Buying Guide: Metal Lathe Cutting Tools You Need Now

Buying Guide for Metal Lathe Cutting Tools

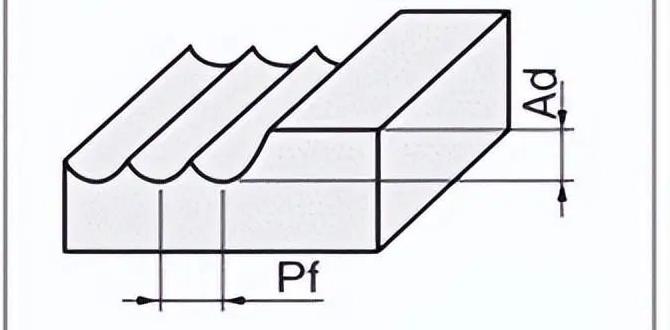

Selecting metal lathe cutting tools can feel overwhelming. First, consider the type of metal you’ll work with. High-speed steel (HSS) tools are versatile and easy to find. Carbide tools, while more expensive, last longer and cut harder materials. Look for tools that suit your lathing projects. Don’t forget to check the tool size and shank style to match your lathe. Have you ever wondered how precise tools can improve your projects? Investing in the right tools can lead to impressive results!Understanding Metal Lathe Cutting Tools

Definition and function of metal lathe cutting tools. Types of cutting tools available for lathes.Metal lathe cutting tools are special devices that remove material from metal pieces. Think of them as the scissors of the machine world! They come in various shapes and sizes for different tasks. The most common types include carbide tips, HSS (high-speed steel), and ceramic tools. Each type serves a unique role, like a superhero team, helping you achieve the best results for your projects.

| Type of Tool | Material | Best Use |

|---|---|---|

| Carbide Tips | Tungsten | Rough cutting |

| HSS | Steel | General work |

| Ceramic Tools | Ceramic | High-speed cutting |

Choosing the right tool can make your projects a breeze, or a total mess. So, remember, tools are like friends—pick the right ones for your adventures!

Factors to Consider When Buying Metal Lathe Cutting Tools

Material compatibility (e.g., steel, aluminum, brass). Tool geometry and design impacts on performance.Choosing the right metal lathe cutting tools can feel like picking the best ice cream flavor—so many options! First, think about material compatibility. Are you working with steel, aluminum, or brass? Each needs different tools. Next, consider the geometry and design of the tools. A well-designed tool can make cutting easier and faster, like having a superhero for your lathe! Here’s a table to help you understand:

| Material | Recommended Tool Geometry |

|---|---|

| Steel | Sharp cutting edges |

| Aluminum | Wide flutes for chip removal |

| Brass | Smooth finishes |

With these factors in mind, you’ll be ready to create amazing projects without a hitch!

Types of Metal Lathe Cutting Tools

HighSpeed Steel (HSS) vs. Carbide tools. Specialized tools for specific applications (e.g., threading, facing).When choosing metal lathe cutting tools, you’ll find two stars of the show: High-Speed Steel (HSS) and Carbide tools. HSS is like the friendly neighbor – affordable and great for many tasks. Carbide, however, is the superstar with strength and durability that loves to tackle tough jobs. Need to thread a screw? Facing a surface? There are specialized tools for that too! They make your work easier and faster. Remember, the right tool can save you time and frustration, so pick wisely!

| Type of Tool | Pros | Cons |

|---|---|---|

| High-Speed Steel (HSS) | Cost-effective, versatile | Wears faster, less durable |

| Carbide | Durable, retains sharpness | Higher cost |

Evaluating Tool Quality and Brand Reputation

Importance of brand reliability in cutting tools. Identifying highquality manufacturing standards.Choosing the right cutting tools is vital. You want tools that last. Reliable brands build trust. They ensure quality, which means better work for you. Look for tools made from strong materials. High-quality standards lead to better results. Remember, a good tool can save you time and effort.

Why is brand reliability important?

Brand reliability is key. It shows that a brand delivers safe and effective tools. You can depend on these brands for consistent performance.

How can I spot high-quality manufacturing standards?

- Check reviews and ratings of the brand.

- Look for durable materials like steel.

- Choose companies with warranties or guarantees.

Cost Considerations for Metal Lathe Cutting Tools

Budgeting for tools and the longterm investment aspect. Understanding pricing variations based on material and brand.Buying metal lathe cutting tools can feel like shopping for candy. You want the best, but you also need to keep your wallet happy! Start by deciding your budget. Cheaper tools might save you money now, but better tools last longer. Consider this: top brands often charge more due to quality. Here’s a quick look at how pricing can vary:

| Material | Low-End Price | High-End Price |

|---|---|---|

| High-Speed Steel | $20 | $50 |

| Carbide | $30 | $100 |

| Cobalt | $40 | $150 |

Choosing wisely now means fewer trips to the tool store later. It’s all about weighing short-term costs against long-term benefits. Remember, a wise buyer knows that investing in quality pays off. Happy shopping!

Where to Purchase Metal Lathe Cutting Tools

Comparison of local suppliers vs. online marketplaces. Evaluating warranties and return policies.Finding the best place for metal lathe cutting tools can be tricky. Local suppliers offer hands-on help, while online marketplaces provide a wider selection. You might enjoy chatting with friendly staff or comparing prices from your home. Remember to check:

- Warranties to protect your purchase.

- Return policies in case something goes wrong.

Where is the best place to buy metal lathe cutting tools?

Local stores provide immediate assistance while online shops often have better deals and variety.

Maintenance Tips for Longevity of Cutting Tools

Best practices for cleaning and storing tools. Recognizing when to sharpen or replace cutting tools.Keeping your cutting tools in shape can be as fun as a game of Tetris! First, always clean your tools after use. Wipe away dirt and shavings to keep them happy. Store them in a dry place to avoid rust. You’ll know it’s time to sharpen them if they start to feel like a dull potato. If they make cutting a struggle, it might be time to let them retire. Here’s a quick table to help:

| Task | Frequency |

|---|---|

| Clean Tools | After each use |

| Check Sharpness | Before each session |

| Replace Tools | When damaged or worn |

Following these tips can keep your tools sharper than a ninja’s sword! Stay consistent and your tools will last a long time.

Common Mistakes to Avoid When Buying Cutting Tools

Overspending on unnecessary features. Not considering the specific needs of your lathe work.Buying cutting tools can be tricky. One big mistake is overspending on features you won’t use. It’s like buying a sports car just to drive to the grocery store. You want useful tools, not fancy gadgets! Another common error is not thinking about your specific lathe needs. Each project is different. Using the wrong tool can make you feel like you’re trying to make spaghetti with a hammer! So be smart and choose wisely.

| Mistake | Description |

|---|---|

| Overspending | Buying tools with features you won’t use. |

| Ignoring Needs | Choosing tools that aren’t for your specific tasks. |

Expert Recommendations on Choosing the Right Tool

Insights from professional machinists and industry experts. Recommended toolsets for beginners vs. experienced users.Choosing the right cutting tool can feel like picking the perfect pizza topping—almost as tricky as deciding between pepperoni and extra cheese! Professionals suggest starting with versatile sets for beginners, like high-speed steel tools, so you can handle a variety of projects. For those with more experience, a set with carbide inserts might be a better fit. This selection can speed up work and improve accuracy.

| Skill Level | Recommended Toolset |

|---|---|

| Beginner | High-Speed Steel Tools |

| Experienced | Carbide Inserts |

Remember, the right tools make a world of difference. Happy machining!

Conclusion

In conclusion, a buying guide for metal lathe cutting tools helps you choose the right tools for your projects. Look for quality, size, and material when selecting. Remember to consider your specific needs and budget. Now that you know these tips, explore more resources or visit a local store to see tools in person. Happy crafting!FAQs

What Are The Different Types Of Cutting Tools Available For Metal Lathes, And How Do I Choose The Right One For My Project?There are several types of cutting tools for metal lathes. Some common ones are high-speed steel (HSS) tools, carbide tools, and ceramic tools. HSS tools are great for beginners because they are easy to sharpen. Carbide tools last longer and cut harder metals, but they can be more expensive. To choose the right tool, think about the metal you are working with and how precise you need to be.

How Do I Determine The Appropriate Material For Metal Lathe Cutting Tools Based On The Type Of Metal I Am Working With?To pick the right material for your cutting tools, first, think about the metal you’re working with. Softer metals like aluminum need sharper tools, often made from high-speed steel (HSS). For harder metals, you might want tools made from carbide because they last longer. You can check the metal’s hardness to help you decide. Always choose a tool that matches the metal for the best results!

What Factors Should I Consider When Evaluating The Durability And Lifespan Of Metal Lathe Cutting Tools?When you check how long metal lathe cutting tools last, think about the material they’re made from. Harder materials usually last longer. Also, consider how you plan to use them. If you use them a lot or in tough conditions, they might wear out faster. Lastly, look for tools that have good reviews from other users.

Are There Particular Brands Or Manufacturers Known For Producing High-Quality Metal Lathe Cutting Tools?Yes, some brands make really good metal lathe cutting tools. You might hear about brands like HSS (High-Speed Steel), which are tough and last a long time. Other good names are Kennedy and GTI. These companies are known for making tools that help you cut metal easily and well.

How Can I Properly Maintain And Sharpen My Metal Lathe Cutting Tools To Ensure Optimal Performance?To keep your metal lathe cutting tools working well, check them often for dullness or damage. When they get dull, you can sharpen them using a sharpening stone or a file. Make sure to clean the tools after use to remove dirt or metal shavings. You should also store them safely to avoid any chips or scratches. Regular care helps the tools last longer and work better.