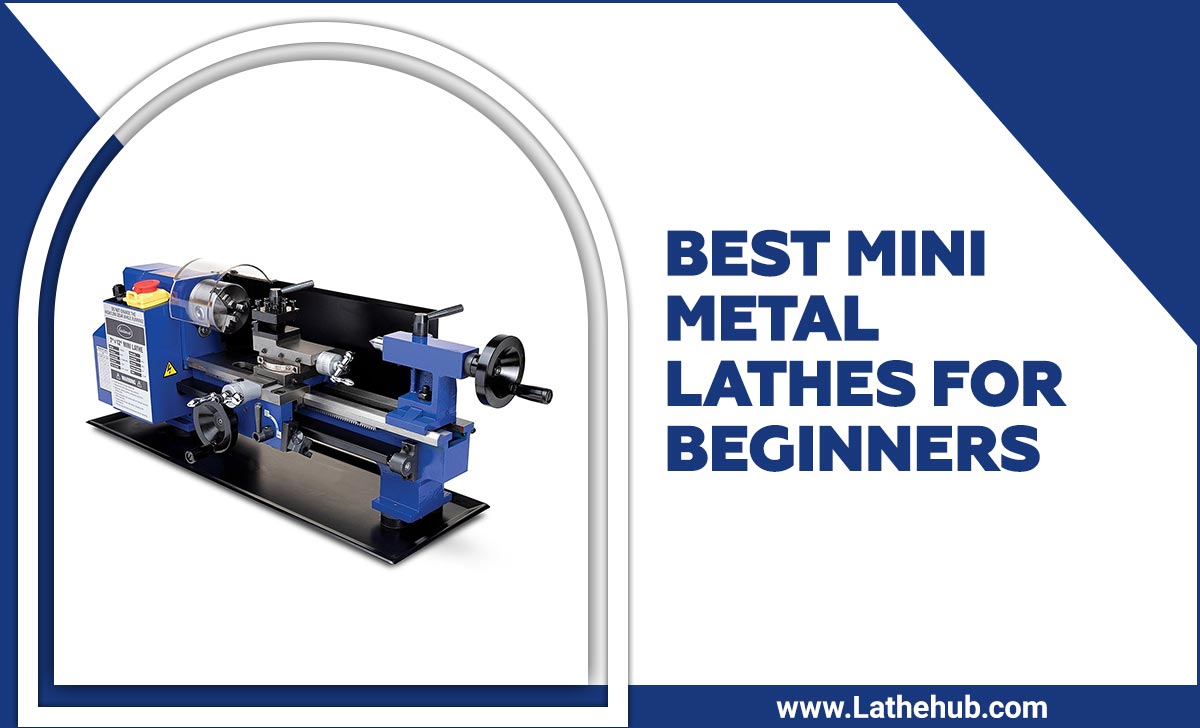

Do you remember when you built your first model or fixed something with your dad? Many people love working with their hands. A metal lathe is a great tool for crafting and fixing. But if you are thinking about buying one, you need to know about the lead screw.

Why does the lead screw matter? This little part helps move the lathe’s cutting tool smoothly. If it’s not right, your projects can go terribly wrong. You might end up with a wobbly piece or a tool that doesn’t cut right. That can be frustrating!

In this buying guide, we will explore everything you need to know about metal lathe lead screws. From what they do to how to pick the best one for your needs, we’ve got you covered. Are you ready to make your crafting adventures even more fun? Let’s dive in!

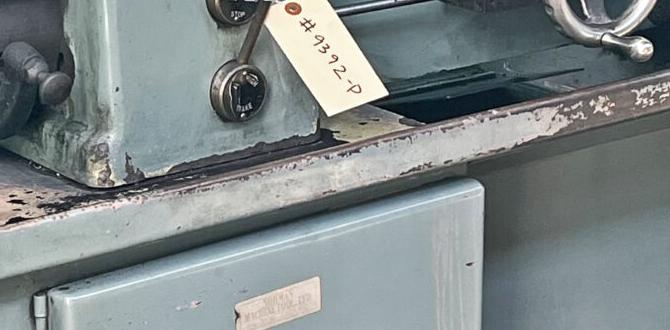

Essential Buying Guide For Metal Lathe Lead Screw Systems

Buying Guide for Metal Lathe Lead Screws

Are you looking to improve your metal lathe experience? Understanding lead screws is key! They help control movement efficiently. A good lead screw enhances precision and durability. Do you know the different types? Some are designed for heavy-duty tasks but may cost more. Others are more affordable but might not last as long. Choosing the right lead screw can boost your projects significantly. Explore options that fit your needs and budget for a better crafting journey!Understanding Metal Lathe Lead Screws

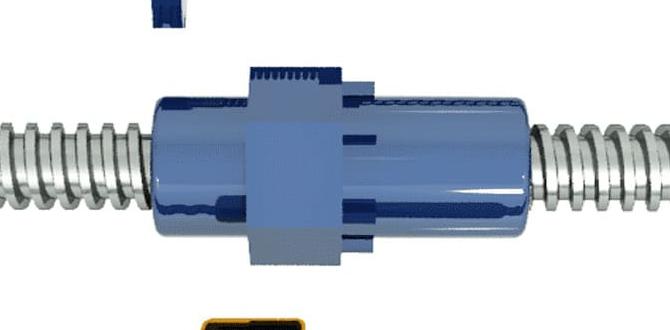

Definition and function of lead screws in metal lathes. Types of lead screws available in the market.Lead screws help move parts on a metal lathe. They ensure precise cuts and adjustments. Without them, working accurately would be hard. There are different types of lead screws you can find:

- Acme Lead Screws: These are strong and durable, making them great for heavy loads.

- Ball Screws: These reduce friction and increase speed for smoother operations.

- Square Threads: They offer good power transmission, often found in heavier machines.

Choosing the right lead screw can improve the performance of your lathe. Think about what you need before buying.

What do lead screws do in metal lathes?

Lead screws aid in precise movements, making metal lathes function accurately for various tasks.

Factors to Consider When Buying a Lead Screw

Material quality and durability options. Thread pitch and its importance for machining precision. Length and compatibility with existing lathe models.Choosing the right lead screw can make your work easier and more precise. Here are key points to keep in mind:

- Material Quality: Strong materials last longer. Look for metal that can handle wear and tear.

- Thread Pitch: This affects how smooth your cuts are. Smaller pitches offer better accuracy.

- Length: Ensure the screw fits your lathe model. Measure twice before buying.

Consider these factors to get the best results from your metal lathe.

What should I look for in a lead screw?

Focus on material quality, precision thread pitch, and length. These factors help your lathe run smoothly and last longer.

Different Types of Lead Screws Explained

Acme lead screws vs. trapezoidal lead screws. Ball screws versus traditional lead screws.Lead screws come in various types, each useful for different tasks. Acme lead screws have a trapezoidal shape. This design helps them move easily and handle heavy loads. Trapezoidal lead screws are similar but can provide more precision. Ball screws are even better. They use tiny balls to reduce friction. This means they are faster and require less power than traditional lead screws. Both types serve unique purposes in machines. Choosing the right one is key for smooth operations.

What are the main differences between acme and trapezoidal lead screws?

Acme lead screws are good for heavy loads, while trapezoidal screws offer more precision. Acme screws are commonly used for general tasks, whereas trapezoidal screws suit applications needing high accuracy.

Why are ball screws better than traditional lead screws?

Ball screws have lower friction, leading to higher speeds. They require less power to operate than traditional lead screws, making them more efficient.

Installation Tips for Metal Lathe Lead Screws

Tools and equipment required for installation. Common installation mistakes to avoid.Start with the right tools for a smooth installation. You’ll need a wrench, screwdriver, and a good sense of humor! Don’t forget to wear safety goggles—your eyes are precious! Common mistakes often include not aligning parts properly. Make sure everything fits like a glove to avoid future headaches. Lastly, double-check your work. If you skip this step, you might as well be looking for a needle in a haystack!

| Tools Needed | Common Mistakes |

|---|---|

| Wrench | Misalignment of parts |

| Screwdriver | Not securing screws properly |

| Safety goggles | Skipping the double-check |

Maintenance Practices for Longevity

Regular inspection and lubrication schedules. Signs of wear and when to replace lead screws.To keep your metal lathe working well, it’s essential to check it often. Set up a schedule for inspections and lubrications. This helps you find any problems early. Look for signs of wear on lead screws. Do they feel rough? Are they bent? If they are, it’s time to replace them. Keeping track of these things can help your lathe last longer.

- Check for noise while using.

- Feel for smooth movement.

- Look for visible damage.

How often should lead screws be lubricated?

Lead screws should be lubricated every 50 hours of use. Regular oiling keeps them smooth and prevents wear.

Cost Considerations and Budgeting

Price ranges for different types and brands. How to balance cost with quality and functionality.Thinking about the cost of a metal lathe lead screw? You’re not alone! Prices can swing widely based on the type and brand. You might find a basic model for around $200, while top-tier options can soar to $2,000 or more. Balancing cost with quality is like trying to ride a unicycle while juggling. Seems tough, but it’s doable! Look for features that suit your needs without breaking the bank. Below is a quick price comparison:

| Type | Price Range | Quality |

|---|---|---|

| Basic Lead Screw | $200 – $500 | Good for starters |

| Mid-Range Lead Screw | $500 – $1,200 | Durable and efficient |

| High-End Lead Screw | $1,200 – $2,000+ | Top-notch performance |

Remember, quality often shines brighter than price. You don’t want a lead screw that feels like it was made from Lego bricks. Choose wisely!

Frequently Asked Questions About Lead Screws

Common queries new buyers have. Troubleshooting tips for lead screwrelated issues.New buyers often have questions about lead screws. Here are some common ones:

Is it normal for my lead screw to wobble?

Yes, a slight wobble can happen. It may mean the screw is not aligned correctly. Check if it’s secure in its mount.

What if my lead screw won’t turn?

If it won’t turn, check for obstructions. Dirt or debris may block movement. Cleaning can help solve this issue.

How can I maintain my lead screw?

Regular maintenance helps keep it in good shape. Here are some tips:

- Keep it clean.

- Lubricate it often.

- Check for wear and tear.

With these tips, you can enjoy using your lead screw more efficiently!

Conclusion

In conclusion, a buying guide for metal lathe lead screws helps you choose the best one for your needs. Remember to check the size, material, and compatibility with your lathe. By doing your research, you can make an informed choice. If you want to learn more, explore reviews or tips on installation. Happy lathe crafting!FAQs

Sure! Here Are Five Related Questions About Buying A Metal Lathe Lead Screw:When buying a metal lathe lead screw, check its size to make sure it fits your lathe. You should also look for the material, as some are stronger than others. Price matters, so compare options to find one that suits your budget. It helps to read reviews from other buyers to see if they liked it. Finally, ask about the warranty, which can protect you if something goes wrong.

Sure! Please provide me with the question you’d like me to answer.

What Are The Key Factors To Consider When Selecting A Lead Screw For A Metal Lathe?When choosing a lead screw for a metal lathe, you need to think about a few important things. First, consider the length of the lead screw. It should fit your lathe well. Next, check the thread size. Larger threads can handle heavier tasks. Also, think about the material. Strong materials will last longer. Finally, make sure it moves smoothly and fits your style of work!

How Do The Materials Used In Lead Screws Affect Their Performance And Durability?The materials in lead screws matter a lot. When we use strong materials like steel, the screws last longer. They can handle heavy loads without breaking. Softer materials might wear out quickly and cause problems. So, choosing the right material helps make lead screws work better and last longer!

What Are The Differences Between Acme Screws And Ball Screws In Terms Of Efficiency And Precision For Metal Lathes?Acme screws are simple and good for basic tasks. They can handle heavy loads but may not be very precise. Ball screws are better for precision. They use small balls to move smoothly, so they are more efficient for detailed work. If you want speed and accuracy on a metal lathe, ball screws are usually the best choice.

How Can I Determine The Appropriate Lead Screw Length And Diameter For My Specific Lathe Model?To find the right lead screw length and diameter for your lathe, first check the manual. It usually has the needed measurements. If you don’t have the manual, measure the old lead screw if possible. For diameter, look for what fits snugly but can still move easily. If you are unsure, ask someone at a hardware store for help.

What Are The Common Signs Of Wear And Failure In Lead Screws, And How Can I Maintain Them For Optimal Performance?Lead screws are important parts that help machines move. Common signs of wear include squeaking sounds, rough movement, and visible damage. To keep them working well, you should clean them regularly and add grease to help them move smoothly. Check for any bent or broken parts and replace them if needed. Taking care of lead screws means they last longer and work better!