Do you love creating things with your hands? Metal lathes let you make amazing parts and tools. But how do you choose the right one? The saddle is a key part of any metal lathe. It helps the lathe move smoothly and accurately. Buying a metal lathe saddle can feel overwhelming. With so many options, how can you pick the best one?

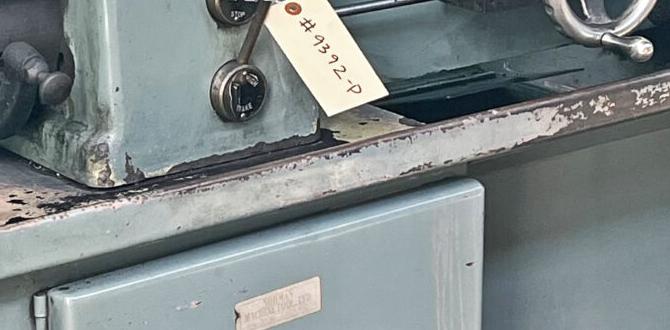

Imagine you’re in a workshop. You see a shiny lathe, but its saddle looks old and worn. Can it still work like new? Often, the saddle makes a big difference in how well your lathe performs. A good saddle means more precise cuts and a better end product.

In this buying guide, we’ll explore what to look for in a metal lathe saddle. By the end, you’ll feel confident about your choice. Let’s dive into the details and make your metalworking dreams a reality!

Buying Guide: Metal Lathe Saddle For Precision Crafting

Buying Guide Metal Lathe Saddle

Are you thinking about purchasing a metal lathe saddle? This part is crucial for smooth and precise machining. A good saddle helps the tool move smoothly across the metal. When selecting one, check for durability, compatibility, and ease of use. Did you know that the right saddle can save you time and reduce wear on other parts? It’s like having the perfect partner in your workshop. Overall, a quality metal lathe saddle makes a big difference in your projects.Understanding Metal Lathe Saddles

Definition and purpose of a metal lathe saddle. Types of metal lathe saddles available in the market.A metal lathe saddle is an essential part of a lathe machine. It holds the tool or workpiece in the right position. This helps shape metal accurately. There are different types of saddles available to fit various lathes. These include:

- Flat saddles – simple design for stability.

- Compound saddles – allows for more angles.

- Sliding saddles – move easily for precision work.

Choosing the right saddle matters for better results in your projects.

What is the purpose of a metal lathe saddle?

The metal lathe saddle supports tools and workpieces. It ensures they stay in the right place while cutting. This way, you get smooth and clean shapes.

What types of metal lathe saddles do I need?

Look for a saddle based on your lathe type. For example, beginners might prefer a flat saddle for ease. Meanwhile, advanced users might find a compound saddle more helpful.

Key Features to Consider

Material quality and durability. Size and compatibility with different lathes.Choosing a metal lathe saddle? Focus on a few key features. First, the material quality and durability are vital. Look for strong metals that can withstand heavy use. Next, the size and compatibility matter. Ensure it fits your lathe perfectly. A good fit helps with smooth operation.

- Strong iron or steel lasts longer.

- Check size before you buy.

- Compatibility with your lathe is crucial.

Why is material quality important?

Material quality ensures your saddle can handle tough jobs. A durable saddle makes your work easier and lasts longer.

What size should I look for?

The size must match your lathe. A good fit leads to better performance and safety while working.

Benefits of Upgrading Your Metal Lathe Saddle

Enhanced precision and accuracy in machining. Improved stability and reduced vibrations during operation.Upgrading your metal lathe saddle can make a big difference. With a new saddle, you’ll see enhanced precision and accuracy in your machining tasks. Imagine making parts that fit perfectly! Better saddles also improve stability and reduce those pesky vibrations during operation. Less wobble means smoother cuts, and who wouldn’t like their lathe to hum a happy tune instead of shaking like a maraca? It’s like giving your machine a spa day!

| Benefits | Description |

|---|---|

| Enhanced Precision | Gives you better fitting parts. |

| Improved Stability | Reduces vibrations for smoother operation. |

Important Specifications to Look For

Weight capacity and load distribution. Dimensions and fitting options.Choosing a metal lathe saddle? Pay attention to its weight capacity and how it distributes load. If it can’t handle the weight, you might end up with a surprise that’s heavier than a sumo wrestler on a seesaw! Also, look at the dimensions and fitting options—these ensure your metal lathe will snugly fit in your workshop like a cat in a sunbeam.

| Specification | Importance |

|---|---|

| Weight Capacity | Ensures stability and safety. |

| Load Distribution | Prevents wear and tear. |

| Dimensions | Facilitates proper fit. |

| Fitting Options | Allows customization in setup. |

Common Mistakes to Avoid When Buying

Misjudging size compatibility. Ignoring user reviews and expert recommendations.One big mistake is misjudging the size compatibility of your saddle. Always check if it fits your metal lathe first. Buying a saddle that’s too big or too small is like trying to wear your dad’s shoes—your feet might not even fit!

Another pitfall is ignoring user reviews and expert advice. User reviews are like treasure maps—they guide you to the best products. Experts have experience, so listen up! You wouldn’t ask a cat for dog training tips, right?

| Common Mistake | Why to Avoid |

|---|---|

| Misjudging Size | Can lead to poor performance. |

| Ignoring Reviews | You miss out on valuable insights! |

Frequently Asked Questions (FAQs)

Answers to common queries about metal lathe saddles. Maintenance tips and best practices.Many people wonder about metal lathe saddles, and that’s totally normal! Here are some answers to common questions. First, how often should you maintain your saddle? It’s best to check it every few weeks. This keeps it happy and working well! Normally, keeping it clean can avoid a lot of problems. If your saddle starts making weird sounds, it may be time to inspect it. Remember, a well-cared saddle can last for years! Need more tips? Here’s a fun table:

| Tip | Frequency |

|---|---|

| Clean it | Every few weeks |

| Check for wear | Monthly |

| Lubricate parts | Every 3 months |

Staying on top of these tips means less time worrying and more time crafting! Now that’s a win-win, right?

Where to Buy Metal Lathe Saddles

Recommended online retailers and local suppliers. Tips for assessing seller reliability and product authenticity.Buying a metal lathe saddle can feel like a treasure hunt! For the best deals, check out online retailers like Amazon or eBay. Local suppliers might surprise you too! A quick visit can be fruitful. But remember, not all sellers are created equal. Look for customer reviews. If they have lots of happy buyers, that’s a good sign! Likewise, beware of prices that seem too good to be true. They usually are, just like my attempts at baking!

| Online Retailer | Local Supplier |

|---|---|

| Amazon | Hardware Stores |

| eBay | Specialty Shops |

| AliExpress | Local Craft Fairs |

Checking seller reliability is key! If a seller has a return policy, it often means they trust their product. Also, ask about warranty or authenticity. After all, you want a sturdy saddle that won’t freak out on you like my pet parrot during a thunderstorm!

Additional Resources and Further Reading

Links to relevant articles and guides. Recommendations for forums and communities for enthusiasts.For those eager to learn more about metal lathes, there are helpful resources available. Reading articles can provide even more insight. Online forums connect you with other enthusiasts who share tips and advice. Some great places to check out include:

- Lathes.co.uk – Comprehensive lathe guides

- Reddit’s Metalworking community

- Hobby Machinist – Forums and support

These resources offer valuable information and support for your journey.

Where can I find helpful articles on metal lathes?

Helpful articles on metal lathes can be found on specialized websites and forums. They often cover different models and techniques. A search for “metal lathe guides” can yield many results.

Conclusion

In conclusion, a buying guide for metal lathe saddles helps you choose the right one. Focus on compatibility, material quality, and size. Remember to consider your specific needs, like budget and projects. We encourage you to do more research and read reviews to make an informed decision. Happy crafting with your new lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe Saddle:Sure! When buying a metal lathe saddle, think about its size and fit for your lathe. You also want to check how strong and sturdy it is. Look for good reviews from others who have bought it. Make sure it matches your budget, too. Finally, ask if there is a warranty, so you are protected if something goes wrong.

Sure! Please share the question you’d like me to answer, and I’ll help you with it!

What Factors Should I Consider When Choosing A Metal Lathe Saddle For My Specific Lathe Model?When picking a metal lathe saddle, think about your lathe’s size and model. You want it to fit perfectly. Check the weight capacity to make sure it can hold what you will be using. Look at the materials for strength and durability. Finally, read reviews to see what other users think.

How Do I Determine The Appropriate Size And Weight Capacity Of A Metal Lathe Saddle For My Machining Projects?To find the right size and weight capacity for a metal lathe saddle, first think about what you’re making. You need to consider the largest part you’ll work on. Check how heavy the pieces are too. A larger saddle can hold bigger and heavier pieces better. Always use a saddle that is strong enough for your biggest projects.

What Materials Are Commonly Used In The Construction Of Metal Lathe Saddles, And How Do They Impact Performance?Metal lathe saddles are often made from cast iron and steel. Cast iron is strong and dampens vibrations, which helps make smoother cuts. Steel can be lighter and still very tough, making it easier to move the lathe. Using these materials helps the lathe work better and last longer.

Are There Specific Brands Or Manufacturers Known For Producing High-Quality Metal Lathe Saddles?Yes, some brands are famous for making good metal lathe saddles. Companies like Jet, Grizzly, and Sieg make reliable ones. These brands are known for being strong and lasting a long time. You can trust them if you want a sturdy metal lathe saddle.

What Maintenance Practices Should I Follow To Ensure The Longevity And Precision Of My Metal Lathe Saddle?To keep your metal lathe saddle working well, clean it often. Use a soft cloth to wipe away dust and oil. Check for loose screws and tighten them if needed. Always use the right oil to keep parts moving smoothly. Lastly, keep the lathe in a safe, dry place to avoid rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Buying A Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When buying a metal lathe saddle, think about its size and fit for your lathe. You also want to check how strong and sturdy it is. Look for good reviews from others who have bought it. Make sure it matches your budget, too. Finally, ask if there is a warranty, so you are protected if something goes wrong.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer, and I’ll help you with it!”}},{“@type”: “Question”,”name”: “What Factors Should I Consider When Choosing A Metal Lathe Saddle For My Specific Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a metal lathe saddle, think about your lathe’s size and model. You want it to fit perfectly. Check the weight capacity to make sure it can hold what you will be using. Look at the materials for strength and durability. Finally, read reviews to see what other users think.”}},{“@type”: “Question”,”name”: “How Do I Determine The Appropriate Size And Weight Capacity Of A Metal Lathe Saddle For My Machining Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right size and weight capacity for a metal lathe saddle, first think about what you’re making. You need to consider the largest part you’ll work on. Check how heavy the pieces are too. A larger saddle can hold bigger and heavier pieces better. Always use a saddle that is strong enough for your biggest projects.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Construction Of Metal Lathe Saddles, And How Do They Impact Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe saddles are often made from cast iron and steel. Cast iron is strong and dampens vibrations, which helps make smoother cuts. Steel can be lighter and still very tough, making it easier to move the lathe. Using these materials helps the lathe work better and last longer.”}},{“@type”: “Question”,”name”: “Are There Specific Brands Or Manufacturers Known For Producing High-Quality Metal Lathe Saddles?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some brands are famous for making good metal lathe saddles. Companies like Jet, Grizzly, and Sieg make reliable ones. These brands are known for being strong and lasting a long time. You can trust them if you want a sturdy metal lathe saddle.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should I Follow To Ensure The Longevity And Precision Of My Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe saddle working well, clean it often. Use a soft cloth to wipe away dust and oil. Check for loose screws and tighten them if needed. Always use the right oil to keep parts moving smoothly. Lastly, keep the lathe in a safe, dry place to avoid rust.”}}]}