Have you ever wondered how metal lathes work? They help create amazing things from metal. The tailstock is an important part of the lathe. But what should you look for when buying a metal lathe tailstock?

Imagine you are in a workshop, shaping metal into smooth forms. The tailstock helps support the workpiece. If it’s not right, your projects could suffer. So, how do you choose the best one?

In this buying guide, we will explore key points to consider. You’ll learn about size, material, and features. Many people overlook these details, but they make a big difference. Selecting the right tailstock can lead to better projects and less frustration.

Did you know that the kind of tailstock you pick can change how you work? It can make tasks easier or more challenging. So, let’s dive in and find out what makes a great metal lathe tailstock!

Comprehensive Buying Guide For Metal Lathe Tailstock

When choosing a metal lathe tailstock, think about your needs. What projects will you tackle? Look for features like easy adjustments and strong build quality. A sturdy tailstock helps you create precise cuts. Did you know that a high-quality tailstock can improve your machining experience? Investing in the right one could make your work smoother and more enjoyable. Remember to check compatibility with your lathe before buying. Happy turning!

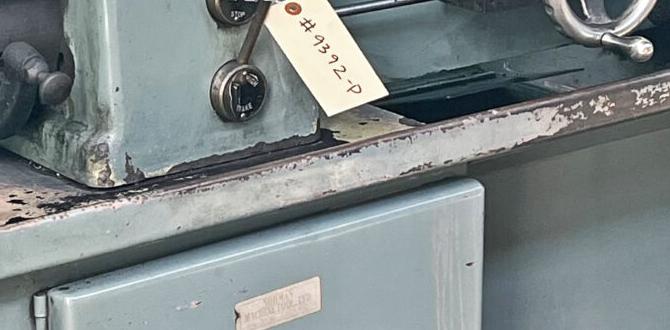

Understanding Metal Lathe Tailstocks

Definition and purpose of a tailstock in metal lathes. Key components and functions of the tailstock.

A tailstock is a part of a metal lathe that supports long pieces of work. It helps keep the material steady during machining. This part has several key functions and components, including:

- Support: Holds the workpiece firmly in place.

- Adjustment: Can be moved to fit different sizes of materials.

- Drilling: Allows drilling holes in the workpiece.

The tailstock is essential for creating accurate shapes and designs. Without it, the work may wobble, leading to mistakes.

What are the main purposes of a metal lathe tailstock?

The tailstock serves many important roles. It stabilizes the workpiece, allows for drilling, and can be adjusted for various sizes. The tailstock ensures precision and safety in any metalworking project.

Types of Tailstocks

Manual vs. automatic tailstocks. Fixed vs. sliding tailstocks.

Tailstocks come in different types, which help in various tasks. First, there are manual and automatic tailstocks. Manual tailstocks need you to move them by hand, while automatic ones adjust by themselves. This saves you time and effort. Next, we have fixed and sliding tailstocks. Fixed tailstocks stay in one place, and sliding ones can move along the lathe. Choosing the right type depends on your project needs.

What are the main types of tailstocks?

- Manual vs. Automatic: Manual requires hand operation. Automatic adjusts automatically.

- Fixed vs. Sliding: Fixed stays in one spot. Sliding can move along.

Key Features to Consider

Material quality and durability. Tailstock alignment and precision. Size and compatibility with various lathe models.

When shopping for a tailstock, focus on three important features. First, look at the material quality and durability. A sturdy construction means your tailstock won’t fall apart during a fun project. Next, check the alignment and precision. An accurate tailstock will keep your work from looking like a wobbly rollercoaster ride. Finally, ensure it fits your lathe model. A mismatched tailstock is like wearing shoes two sizes too big—uncomfortable and not very effective!

| Feature | Why It Matters |

|---|---|

| Material Quality | Durable materials make for a long-lasting tailstock. |

| Alignment | Precision ensures smooth operations and great results. |

| Size Compatibility | Fits your lathe, preventing awkward situations. |

Benefits of Upgrading Your Tailstock

Improved accuracy and performance. Enhanced versatility for different machining tasks.

Upgrading your tailstock can bring many benefits. First, it can improve accuracy and performance. A better tailstock holds your workpiece steady, allowing for cleaner cuts. Second, a new tailstock enhances versatility. You can tackle different machining tasks easily. Whether making simple shapes or complex designs, a good tailstock helps you do it all!

Why upgrade a tailstock?

To achieve better precision and increase your ability to work on various projects.

Key benefits include:

- Better stability while machining.

- Ability to use various attachments.

- Improved overall quality of work.

Cost Factors for Metal Lathe Tailstocks

Price range for different types and models. Importance of balancing cost with features and quality.

Metal lathe tailstocks vary in price based on type and features. Basic models start around $100, while high-end options can reach $500 or more. It’s important to think about quality and features. A cheaper tailstock may lack important tools you need. Here are some factors to consider:

- Material quality

- Ease of use

- Durability

- Included attachments

Finding the right balance between cost and features helps ensure you get the best value for your money.

What should I consider when buying a metal lathe tailstock?

Consider quality, durability, and features to make a smart choice. These factors ensure you get a tailstock that lasts and does its job well.

Maintenance Tips for Longevity

Regular maintenance practices to ensure optimal performance. Troubleshooting common issues with tailstocks.

Keeping your tailstock in great shape is like feeding your pet. It needs care! Regular maintenance is key to ensuring smooth performance. Check for wear and tear often. A little oil here and there can do wonders. If you find a problem, don’t panic! Many common issues are easy to fix. Look for loose parts or dirt buildup. A good cleaning can save the day!

| Issue | Solution |

|---|---|

| Loose tailstock | Check and tighten screws |

| Dirt buildup | Clean with a soft cloth |

| Sticking movement | Lubricate with machine oil |

Remember, a happy tailstock gives you happy projects!

Customer Reviews and Testimonials

Insights from users on various tailstock models. Case studies showcasing user experiences and recommendations.

Users often share their experiences with different tailstock models. Many praise the smooth operation and precise adjustments. Here are some findings:

- One user liked the sturdy build of their tailstock. They felt it was reliable for tough projects.

- Another found a particular model easy to set up and adjust. They recommend it for both beginners and pros.

- A customer noted excellent support from the manufacturer. Quick responses made a big difference for them.

These insights help in choosing the right tailstock for your metal lathe. Real-life experiences give a clearer picture than just specs.

What helps a good tailstock stand out?

Stability, precision, and ease of use are key factors that users look for in a tailstock.

Conclusion

In summary, a good metal lathe tailstock is essential for precision work. Look for key features like adjustability and sturdiness. Always consider your project needs when buying. We recommend researching models and reading reviews for the best choice. Next, explore tutorials on how to use your tailstock effectively. Happy turning, and enjoy your crafting journey!

FAQs

What Are The Key Features To Look For When Choosing A Metal Lathe Tailstock?

When choosing a metal lathe tailstock, you should look for a few important things. First, check how easy it is to move and adjust. You want it to slide smoothly. Second, make sure it holds tools tightly so they don’t slip. Lastly, see if it has good build quality, so it lasts a long time.

How Do Different Tailstock Designs Impact The Precision And Stability Of Lathe Operations?

Different tailstock designs can change how well a lathe works. Some tailstocks keep the workpiece steady, which helps make cuts more accurate. If the tailstock is strong and well-built, it won’t wobble. This means your projects will look better and fit together nicely. A good tailstock helps us create things with more precision.

What Is The Importance Of Tailstock Alignment, And How Can It Be Adjusted On A Metal Lathe?

Tailstock alignment is important because it helps make sure our workpieces are straight and accurate. If it’s not aligned, the piece can bend or break. We can adjust the tailstock by loosening some screws and sliding it until it lines up properly. Then we tighten the screws again to keep it in place. This way, our projects will look better and work well!

Are There Specific Materials Or Construction Qualities That Enhance The Durability Of A Tailstock?

Yes, certain materials make a tailstock stronger. For example, using steel is good because it’s tough and lasts a long time. Good design also helps. If the parts fit tightly, they can work better and last longer. We should check these things for a durable tailstock.

How Do I Determine The Compatibility Of A Tailstock With My Existing Metal Lathe Model?

To find out if a tailstock fits your metal lathe, you need to check a few things. First, look at the size of your lathe model. Then, see if the tailstock is meant for that size. You can check the manual for your lathe and the tailstock. It’s also a good idea to ask the store or look online for help.